I agree that a lot of printers benefit from Z-axis braces. I’ve added them to mine (Monoprice Maker Select V2). Unfortunately that didn’t save me from 2 failed attempts at printing the core. My problems seem to be clearly related to the Y-axis motor. For now I’m assuming it’s an overheating problem and will try to address that before I try again.

For those of you that used DOM style tubes (i.e. not stainless) – what did you do to prep them for the paste wax?

I’m thinking I need some brake cleaner or something similar to de-grease them before applying the wax

I think isopropyl would be good maybe 90%+

I ordered from there - exactly the same material, but minimum primo lengths. The cuts look accurate and pretty square, but will need a good bit of finish work. Most of the cuts have a small tab where the tube broke off before it was fully cut through.

That’s what I did

Ugh! I was able to make 3 cuts with one of those before I had blisters on my hands. I broke down and bought a new one with a longer handle. It was worth the money! Made the cuts so much easier.

I thought the blisters were a feature not a bug. Should have also included a link to some leather gloves.

Nice, and just a regular CR-10, but after replacing stuff and soldering, along with the control box being outside the enclosure type thing its in, I think I just had a cable length issue. I lost maybe 5% print area on the right side due to shortening cables.

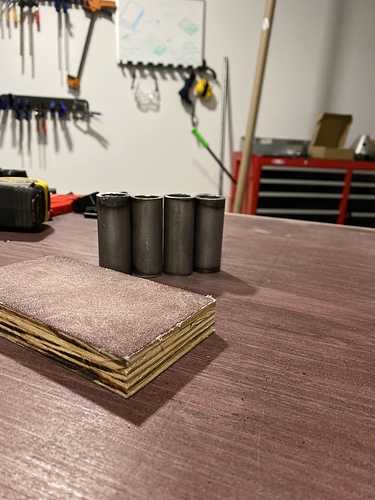

Is 1/2 thick enough for a spoil board? Should I double it up? I want to use clamps and install them barrel screws inside the board as well. The store didn’t have any usable 3/4.

1/2" may be good enough. Depends on your use case.

I used 3/4". I’ve surfaced this board a few times, so it’s not 3/4" anymore. I’m using 15 mm threaded inserts with a 4mm inset so I don’t hit them with a bit if I dig too deep.

15+4 = 19mm… 3/4" is ~19mm. After my surfacing, I’m finding that I’m bottoming out the threaded insert on the layer of wood below it. I actually noticed that the threaded inserts slightly raised the spoilboard.

So this is fun, got my 1" OD tubing from Metal Supermarkets… the OD is 26.5. I was very clear that the ONLY thing I cared about was a 1" OD.

Turns out its 1mm out on 3 pieces only, other 9 are spot on.

That’s still concerning… I wouldn’t have expected that much inconsistency…

Correct me if I am worng but what I understand the original tool holder will not work with the Primo? I have spent way to many hours developing a spindle holder/laser/dust boot to start again. Anyone have a work around?

The Burly tool holder does work with the Primo. I have it mounted and it’s fine.

I’m not sure if the entire Z axis (including lead screw location) is interchangeable, but the distance between the tubes, the mounting plate and holes in the Z tubes are compatible.

I’m using my entire burly z so my 660 is free for figuring out how to follow along with the speed control.

I have the orginal 525. Is this 525 tool holder compatible?

Pretty sure it is, since the 525 to Burly was an incremental update that strengthened some parts but didn’t break compatibility with any major dimension changes.

Mirror truck printed fine, so I’d guess it’s my out of date cooling at cause for the failure on the non-mirror trucks. In sadder news, got ~50% through final truck and ran out of filament. And it’s no longer available on amazon  or elsewhere.

or elsewhere.

There’s an off brand purple silk that literally uses the same photo as the CC3D silk I bought previously, but I dunno that it’s worth the $25 risk.