If I would do it all over again I think some CA glue in there first would be the perfect solution, but who am I kidding, I’m not printing it again.

Yeah, they make black ca too.

They also make a Flexseal spray that works great for sealing up the inside of prints.

I must say, way more printers are having issues with this than I expected. I think the YouTube printer reviewers need to add this part to there printer reviews. I thought the only complaint would be the amount of time, not failures.

Don’t take my epoxy screw up as an issue with the part or the printer. I was just trying to get cute with it and it never crossed my mind that the layers weren’t water tight. Before the epoxy it looked beautiful and was 100% functional, no issues at all. It’s still 100% functional, just maybe not as beautiful since I Bob Rossed it.

When you start selling the plastic in the store offer a “core only” option?

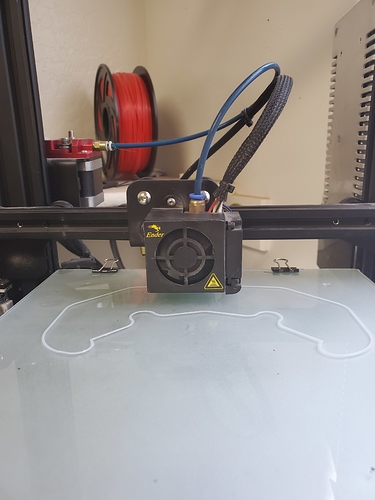

Mine worked on the second try. The image above is blurry, but the part is good. First try was simply a failure in build plate adhesion after 20 hours or so.

I am not an experienced 3D printing guy either, so I don’t think it is too difficult.

Of the 53 parts I printed I had 1 failure and it was due to me not being there to change filament rolls when it ran out. I tried to save it editing gcode and trying to start the print at the right height but I was off layer and it never stuck. And I do not spend ANY time dialing in my printer since I set it up a couple years ago. You’re parts are incredibly designed and robust. If someone is having continual issues, I have to believe it is a printer issue and not a part issue.

I agree with what bill said I have printed all your parts successfully on two different machines. To many variables on how people’s machines are setup or with slicer settings.

Haven’t done the core yet but will be starting tonight and keep you posted on a when it’s done. I don’t have the hardware yet so not sure how the actual parts will fit but the prints themselves feel solid and printed clean.

There’s a raw probability involved too. A part that takes 4x longer to print is 4x more likely to fail (and that doesn’t take into account any of the troubles of printing tall parts). Add to that, you might be printing at heights you haven’t used before (the David problem), and the fact that the torque from the nozzle on a print 140mm on the bed is much higher, and you’re going to get some failures.

Have you had any troubles with your production machines, Ryan?

What about a 2 piece core held together with some big bolts or something?

None yet. I have 3 of them running the parts 24/7 since release.

I think selling just the core in the store would be an awesome option.

And we can special order the color we want…right?

yep you get a choice between black and black

Lost PLA casting in aluminum!

Woah. That would require some above average casting skills, but i like the idea.

Ok, Henry

This would be cool, a core made of solid aluminium.

Using the design as it is, the core would have a weight of 1259g if made of aluminium.

Based on the specific weight of 2.7g/cm³ and the calculated volume of 466.16 cm³ by ’ STL Volume Model Calculator’ on github.

Too heavy? But rigid…

Gosh darn it… I’m now infamous…

I too have thought that an option to buy just the core would be a good one. There’s a lot of people that might not consider building the machine because of the one part. I know I have mine printed now, but I would not have hesitated to buy just the core when I ordered the rest of the parts. Any print longer than 12 hours starts to get intimidating for most people. I mean… you mess it up and you just killed a 300-400g of filament. That’s nearly $6-$10 depending on the brand you use.

My machine is actually pretty reliable, but you have to figure that 130+ hours worth of printing for this machine is more printing than some people do in an entire month of normal prints. If your machine has any weaknesses, this project is likely to find them.

I still think my Y layer shift was due to the stepper driver heating up. Taking the side of my enclosure off fixed my issue with that and I haven’t seen it since.