Nope, not if you go full kit, and I assume you mean controller board then as well.

Awesome thanks

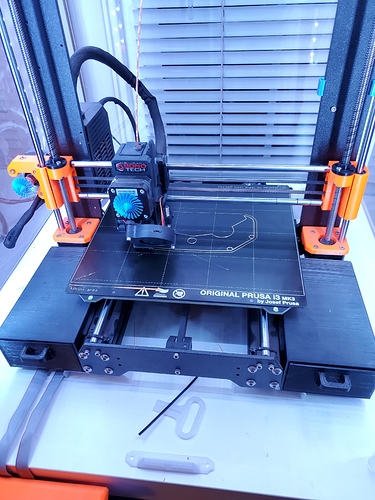

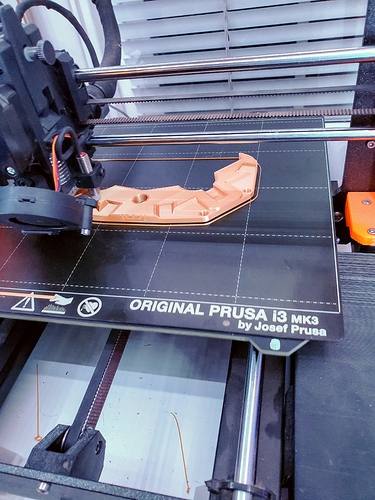

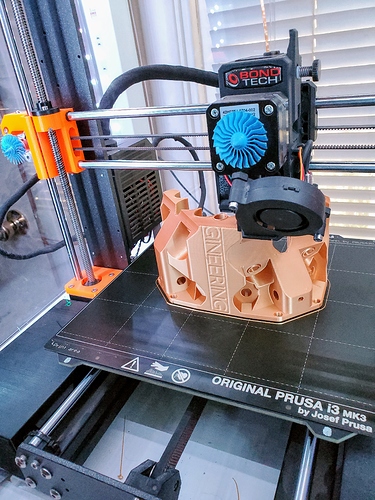

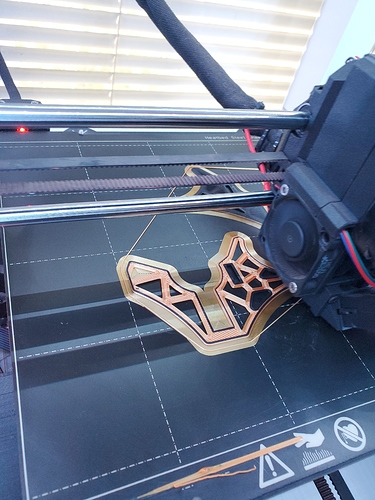

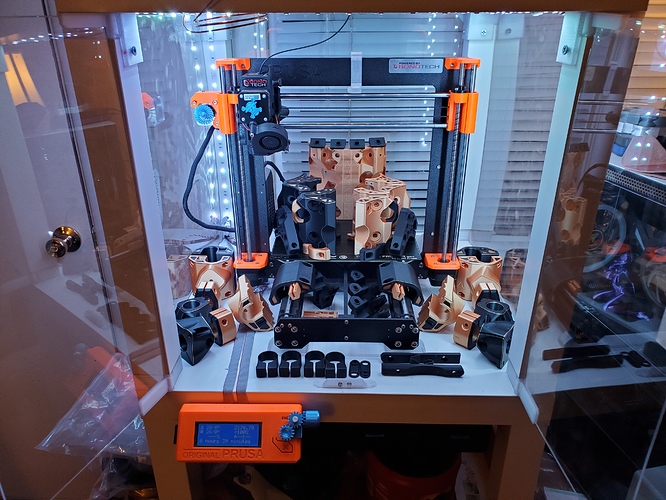

The journey and experience so far has been (aside from a couple failed cores 1 caused by me the other an unknown layer shift.) awesome! I tried to give it some Gusto and experimented with color change for the first time. I am pleased with the results.

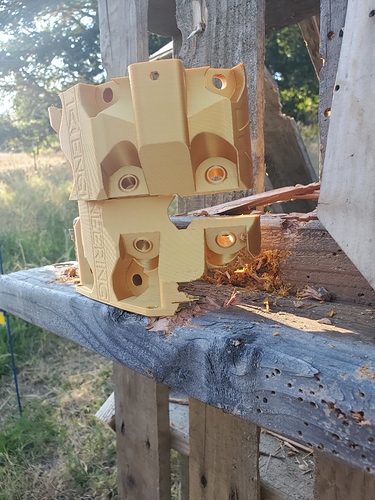

I mentioned at one point that i was going to introduce my failed core to some lead… I wasn’t shooting what i was planning but introductions were certainly made.

When will 25mm release ??

Desperately waiting for the 25mm version. Please release asap so we can test an give feedback on it.

25 mm will be released when

1: Enough burly -> primo upgrades are operational in the wild.

2: Full primo kit has been released for sale in Ryan’s shop.

3: Enough full primo builds are operational.

So we are looking at a number of weeks still, since we are just closing in on the first of three goals, i.e. enough burly/primo upgrades done.

I am not sure whether you were asking for a Makita collet, but I had to order one here: https://www.elairecorp.com/makitaroutercollets.html

There does not seem to be another manufacturer, I am based in Germany.

Am I reading the calculator correctly that the makita router takes up less space than the DW660? if so, what is it’s downside as compared to the 660 (other than price?)

Price.

Even though it takes up less space it is about 8mm further away from the gantry, so the 660 should still be the best option.

My priorities are rigidity, then price.

Hi, I’m new to the forum here. I’ve been following this thread for a while and am preparing to build a Primo. I have a question about the table that isn’t really addressed on the documentation page regarding tables: how flat/level does it need to be? I have built a table mostly out of 2x6 boards, including a table top consisting of several 2x6 boards. The boards aren’t perfectly flat or uniform in thickness, so I’ve done some work a with router and sander to smooth it out, but I’m not sure if it’s enough. Maybe I need to just put a layer of MDF on top. Or, if I could properly level the side rails when I build the MPCNC, could I use the MPCNC to cut away a flat area from the tabletop?

You can put a layer of MDF on top of it to provide a mostly flat surface. Then, once you have the Primo built, you can setup a leveling job and have the CNC work its way across the entire surface milling it flat relative to the CNC itself. That will also account for any imperfections in the leveling of the rails.

how long before the new parts for the 3/4 conduit parts are ready for shipping ?

Plan on several weeks. I believe the plan is to release the full kits for for the J version, then the 25mm version, and finally the "C"onduit version. There is no published timeline.

I am looking forward to upgrading, but I don’t have time to rebuild right now. I am leaving my upgrade kit in the shop for someone else

Basically, that is the way to go.

BUT:

If your machine’s feet are not in one plane, you will / may get a folded surface. Generating a really flat base is not as trivial as it looks. Starting with a good known level plane base plate is useful.

Is that sequence guided by the thought that there are more US-customers’ revenues to be expected from inchy versions than from millimetric ones made in the ROW? If so, understandable, yet not so nice for us non-imperialists

As flat level as you need it. It is a loaded question. I have never really done anythign special to level any of my builds other than do my best to make it flat. My projects are either through cuts, not real leveling needed, or carves that first get surfaced, again, no leveling needed since you are cutting the part level.