Nope. I use 25.4, so I built it first. Edits to make a 25mm are easy so that is next, the 23.5 gave me some issues so I will have to put in more time so it gets to wait until I have time.

You can take your time till mid August, then my printer arrives.

FWIW, My first MPCNC was really wonky and I didn’t notice until I took it apart. It worked great for me, and there’s plenty to learn before making something absolutely “flat”.

Get it about 80% there (whatever that means to you) and you’ll have a good bang for your buck. You can clean up some unflatness by surfacing the spoil board. But if you zoom far enough in, every single build has errors. Don’t kill your momentum worrying about the flatness when you can just cut a tad deeper, and never notice.

Well, I accidentally a core.

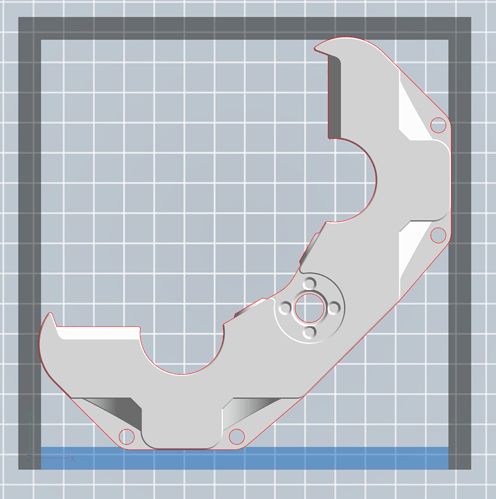

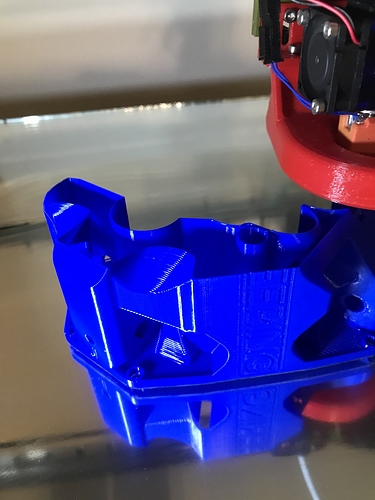

My only working printer is a hand-me down FlashForge Adventurer 3. I wanted to see what problems I’d have running a long print, so I threw the core STL into FlashPrint, set some slightly unrealistic settings (“High quality” and 75% “3D Infill”). I grabbed a roll of white PLA that’s been on my shelf for at least 5 years, though still unopened, and set it running over the holiday weekend. Estimated print time was 48 hours. Actual was about 62 hours. And… no issues.

Since I didn’t expect this to finish, I hadn’t put a lot of effort into calibrating the dimensions before I ran it. Are there some dimensions I can measure on this to verify calibration?

As an aside, that calibration test won’t fit on the FF A3 bed, but the core did, rotated 45 degrees.

Wow! That’s pretty awesome. And man, no room to spare!

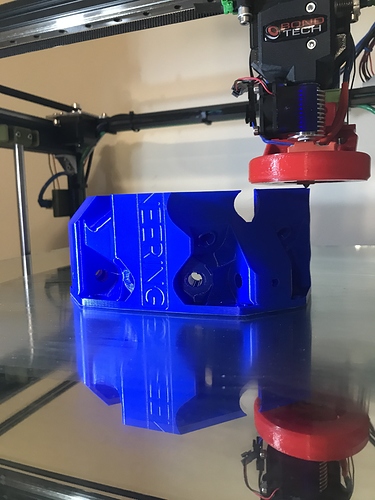

Printed my last part today! Have the table built, the tubes cut, and parts all printed.

Now, I just need the bolts, nuts, screws, and other assorted hardware… Order coming your way, Ryan!

My question was triggered by Stefan’s remarks on step sequences. But I guess it’s alone your decision what you do when, right?

Of course there is no doubt about the genuine priority for 25.4mm (aka 1") tubes on your side of the pond. Glad to hear that 25mm is one of the next essential targets.

Definitely not.

A simple way to at least avoid a surface folded along a diagonal of the working area could be to fix a u-shaped aluminium rail (which should be unbent) between diagonally opponent corners. Make sure a point representing the tool tip is equidistant from the ends of the rail, then look at its center. Same distance? Fine. If not, lower or raise the corners that are part of the folding line.

Certainly not directly necessary when using good plywood, but in the case of the OP who composed his table from single beams, it might help.

The fantastic property of the MPCNC is that you can easily modify and correct any crucial element, always within reasonable limits, of course.

Pure 2D-cutting is uncritical, but the first additional layer can make you scratch deep marks first in your material, then in your head…

Also remember you don’t actually need it level, just flat in relation to your tubes.

How worried should I be that my pipe is 25.6mm instead of 25.4mm? Would you guys advise that I just eat the loss and get the proper pipes now, save myself the heartache? Or can I make this work?

That should be close enough.

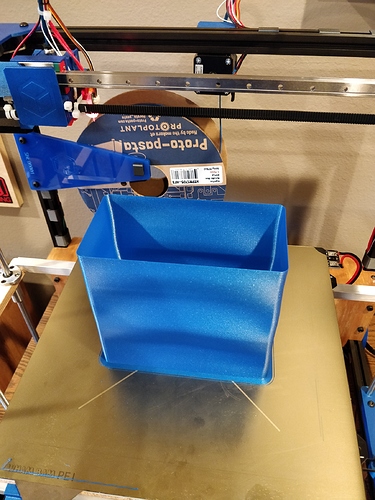

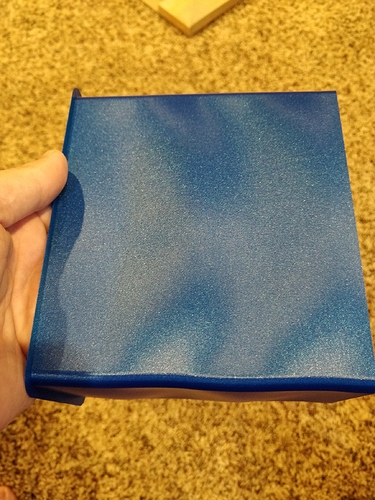

Well, this test object was useful to tell me I can print something that big. And it is pretty neat. But it did the same wobble thing Barry did. It also isn’t useful for squaring, because it is just too floppy. I checked the corners to corners and it looks dead on, but it also is very easy to deform, so I don’t trust the results.

Interestingly, it oscillated in a pretty structured pattern.

Welp, plan B. Thicker.

It is interesting if you look down a corner, it is totally straight, but the other sides were rotating around the corners. When sides 1,3 were widest, sides 2,4 were in the most and vice-versa.

Needs some super sparse infill.

That is an awesome color scheme. What pla is that?

Mika3D silk gold and carbon fiber black

Two layers instead of vase and something like 1% infill…