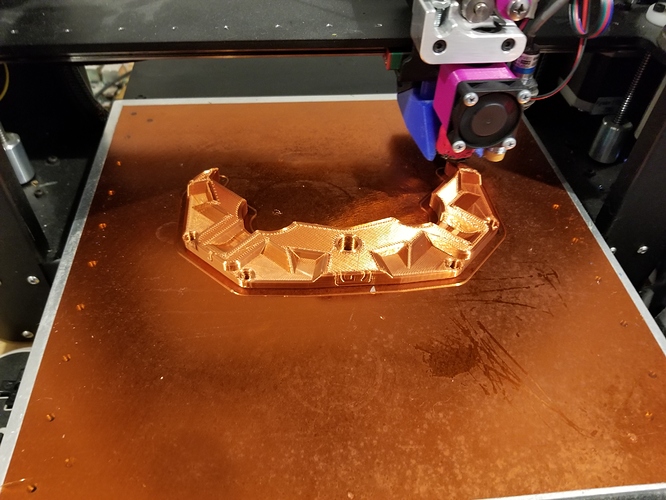

Started on the hardest first. Core at 70% rectilinear, 4 perimeters, 4 layers top/bot. Quoted right around 24hrs.

It really depends on what you are going to do with it, Rick. If you’re going to be doing wood projects then the ideal size is quite a bit different than working in brass or aluminum. It’s easier to start with your needs, then look at sizing the design based on them.

Bill I figure there was a basic size most was going with being smaller then the LR. Will be doing wood as main and if I can figure out if I can do name tags for dog collars then I will give that a shot. I replied back to Ryan’s post though it didn’t seem to show his main topic… It was in response on length of belt to order that it seems everybody is going overboard or just making sure they’re buy enough.

If just for wood a decent size is 24" square. An awful lot of projects will fit that size, and ti’s not going to be too unstable if you need to do something really fine. If you’re going to be working metal then maybe half that size is better. Either way make sure the height isn’t any more than needed for tool changes.

May the odds be ever in your favor!

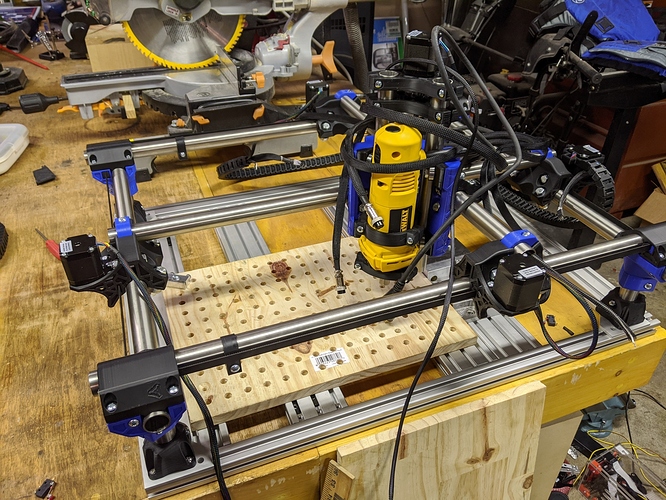

Mine is roughly 24" square. That’s good for wood, and does a fairly good job for engraving metal.

Are we just using bury mounts for now? I dont see primo mounts of any kind anywhere

https://docs.v1engineering.com/mpcnc/PParts/#spindle-options

For things like lasers, pens, needle cutters, you can use the burly mount.

Im aiming for the 660 but that link just reverts me back to the top of the same page

https://www.prusaprinters.org/prints/33165-dewalt-660-mount-for-the-mpcnc-primo

The github looks good too:

As small as you need it. I found now that I have a LR 2x4’, I don’t really need a very big Primo. So I say ideal is the dims from the calc, or smaller. With that you should be able to get the full sized LR extremely square. Squaring a 5’ axis is much easier than a 18" axis. I do agree that you should have both machines though!

https://docs.v1engineering.com/mpcnc/PParts/#spindle-options

In that box I have the mounts I am making in all three places. When I have made all that I think I am going to I will put up some sort of table but for now the 660, both import spindles, and the makita rt700 series have mounts. I still want to add the 611 and a pen/dragknife mount as well as a blank. The blank is going to need some documentation though so it is last.

Thanks for keeping the 611 on your radar. I’m slapping my 660 in the upcoming primo, but I’ve kinda started liking my 611 in the teeny tiny, at least until somebody has the time and inclination to sketch a write up on the pid. Right now digging through that thread is a recipe for me screwing up at least 3 steps and breaking something or starting a fire.

Thanks everyone. 24" squared sounds good. Always have the LR for bigger stuff. Just hated having too big for small projects to where I think be better/cheaper on changing spoil boards.

Seen so many post on calculator. Is it working? Going check see length of pipe for 24" square. (If pipe itself not 24")

Saw that - first on twitter. Is the angle between the ring and the brackets where the fixation screw lives ideal? Would a more streamlined version be, if not better, not worse for the transfer of the compressing force? - BTW, I smiled at your self-classification of your skills…

I once read somewhere that sharp angles are prone to make the object more fragile.

N.B., I am not criticizing - just curious!

Cheers,

U.

Never change a running system. The trend will lead to stacked multi-MPCNCs, with the latest mounted on top. Has anybody ever thought about that?

It is not a good option it has a large gantry offset and will also eat into the build area. The 660 is still the best option with the good import spindle and the makita being second best. After that I do not really recommend anything else.

I was kinda split on that.

May be better in the long run. Don’t have to wear out one tool as fast. Having both Primo and LR.

It avoids the trucks and the corner of the corner, when at 0,0.

Not sure what you are saying here?