yep it is

Cheaped out and went with the Sunsu CF.

In my haste to disassemble my old machines and get ready for the Primo, I forgot to cut my Lowrider2 611 plate, but the rest is good to go.

The Sunsu is 1kg, so I have enough to print the baseplate and play around in the garage while the core is printing.

Hopefully, it goes ok.

I’m holding you responsible.

PETG is more flexible than pla. My petg parts were printed with 4 perimeters and were still flexible. I upped them to 5 or 6. Primo is all pla now though.

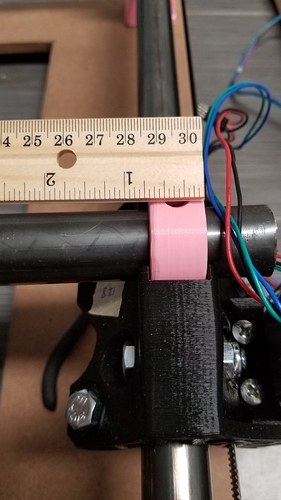

So how exact do the cuts have to be…hand sawing is not the easiest lol. Even used the hose clamp trick. Its suppose to be 34.5 (y Gantry). do I just use this piece for 34.25 (x Gantry) and take it down with the bench grinder.

Edit: the tape measure shifted a bit was kind of hard taken a pick but it’s off by about 1/32 maybe a little more

Yeah at 90% infill, 6 solid top and bottom and 6 walls, my 611 plate bowed so badly, it was a joke.

Went ahead and ordered CF PLA for the core. Rest of my Primo parts seem ok in PETG.

I haven’t built one. But after proof reading the instructions I think the most critical lengths are the feet. The X and Y parts are on long grips so 1/32" shouldn’t be a problem. But maybe someone that has built it would know better.

You can also cut a little wide of the line and then trim it up with a belt grinder or a file and a ton of patience.

Right when I was ready to start printing the Primo in PLA, I couldn’t make a good print to save my life. I tightened things (belts, bolts) and rebuilt the hot end (heat break, heater core, thermistor, nozzle). First 5 prints had a nozzle/hot end plug after about an hour. I changed the retraction settings back to 0.5mm down from 2mm. Now it is printing beautifully. Prusa MK2

I used CF PLA from amazon and they are still in stock

https://www.amazon.com/gp/product/B0837QMVWR/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

Good to know.

The new mk3s firmware screwed up belt status. I spent a day over tightening everything until it was about to snap, finally I realized it was software.

Plus side, if prints don’t go well, belts are so dialed in, that I can rule them out, immediately.

I do have some old pla settings with higher ands faster retraction, but you’re saying you went lower. I’ll keep that in mind if I have issues.

I know what the problem is. My textured PEI sheet. I just love it so much. Spring steel should be easier.

Although, with CF, it looks like, from my limited, after the fact, research, that I need to use .5mm+ nozzle size and hardened steel; or a disposable nozzle. Luckily, all of my .5mm nozzles were super cheap.

Thanks! I went ahead and ordered the Sunsu, earlier.

You can be off a lot. I messed up the placement of my feet in one axis and decided to live with it.

I think an error of 1/2" is fine and 1" would be ok too. I’d bet even 1.5" (centered so 0.75" each end) is probably ok.

Just realized you are talking about the gantry rails, in which case I’d say 1/2 inch (0.25 inch each end) is about the limit I’d feel comfortable with.

That sounds reasonable.

I wish I had left that much out on the gantry it would be easy to make a mount for the cable chain or for the measuring tape.

You could mount the other brother Daryl

I erred on the side of long and cut on the outside of the sharpie line.

Can you tell me the print parameters for the 0.5mm nozzle?

Feedrate 38mm/s

Layerheight?

Quality?

Etc.

Thanks for your awesome work

I did the same as Jamie, I have probably a half inch of plastic showing on one side at the corners. As long as your tubes are solidly captured, a little off isn’t going to hurt anything.

Thanks everyone for the input. Guess I won’t stress it to much then. I held off making any more cuts to see what everyone had to say. Thanks again!

Where will the tool mount be posted Ryan? Thingiverse. or other?