Hi Guys,

Wish me luck, as the title says new build pending. I’m just waiting for a few bits to arrive and the rest of the printed parts to print.

I am thinking of making the YZ and maybe XZ plates out of acrylic. Just not sure on the thickness; maybe 10mm for YZ and 6mm for XZ, but open to suggestions. I will initially be running a SKR, but I may swap this out for a jackpot board at a later date. hopefully adding a Raspberry Pi to the build. Any recommendations on software for the Pi?

Any other advice is always welcome over here.

I look forward to learning all about the world of MPCNC and chatting with you all.

Best of luck! I made both sets of plates out of 12.7mm MDF and painted them black to match my PLA material and for a bit of moisture protection. I have to think 10mm cast acrylic would do it for strength and stability, not sure about the 6mm though…

I’m throwing a Raspberry Pi 4 8GB unit at mine for Repetier-Host testing on a Linux OS and a VNC link to my Windows system for CAD/CAM design adjustments on the fly while in the garage.

No luck needed (unless you plan to chew the acrylic out with your bare teeth). Have fun, and document every step along the way so we can share your success!

In some cases the way is the goal also. ![]()

sounds good buddy i’m hoping I can find or install somthing like fluid or mainsail on the pi to give me wireless and also add a bltouch or similar for bed pobing

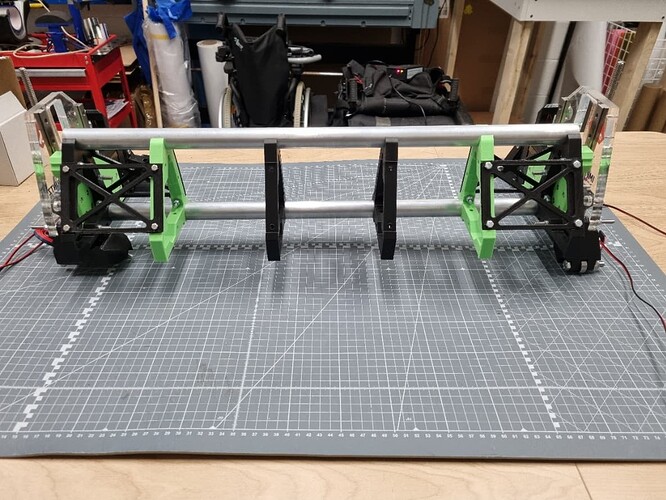

oooooh look whats just arrived

Just waiting for a few more bits of hardware to get here then I can start this build

https://www.amazon.co.uk/dp/B09X5LQS1T?psc=1&ref=ppx_yo2ov_dt_b_product_details

also purchased these https://www.amazon.co.uk/dp/B09XMTKRL5?ref=ppx_yo2ov_dt_b_product_details&th=1

No idea which one does what lol but i’m sure youtube will teach me ![]()

#happydays

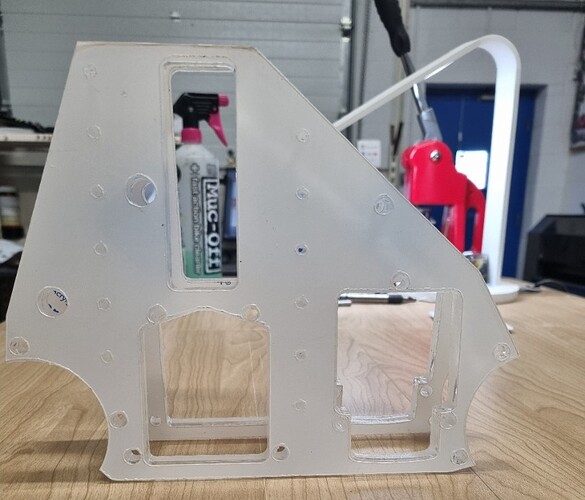

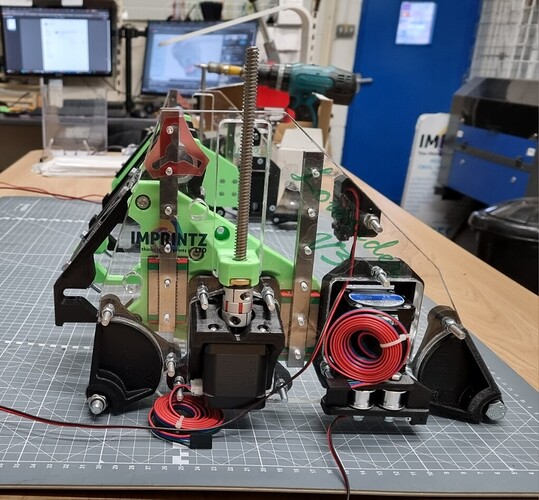

-YZ plates cut on my 50 watt chinese co2 laser using 12mm Cast acrylic.

I was really surprised it cut it and almost all the way through on 1 pass

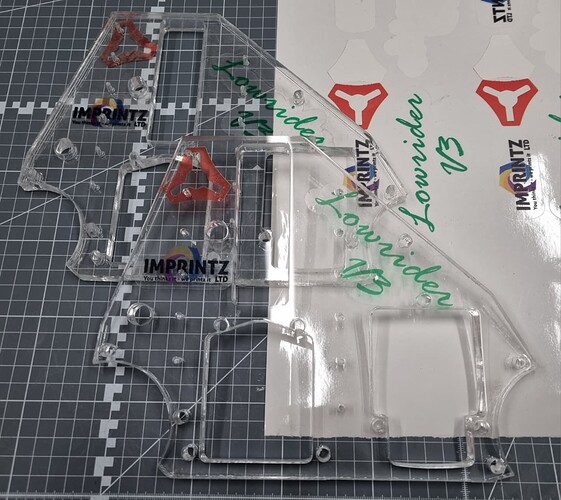

Finaly Made a start ![]()

![]()

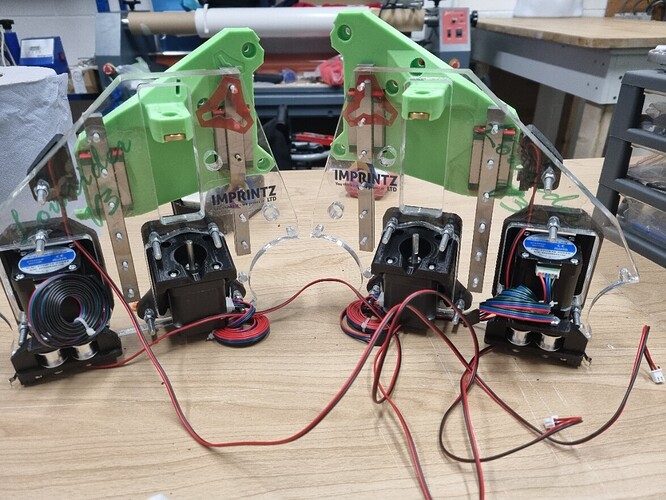

i’ve ordered the parts for dougs mod on the dust extractor just hope ive printed the parts correctly

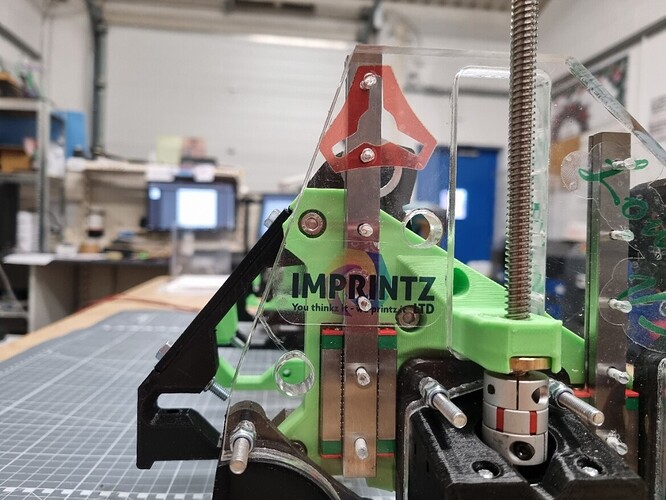

Those 12mm XY plates look great!

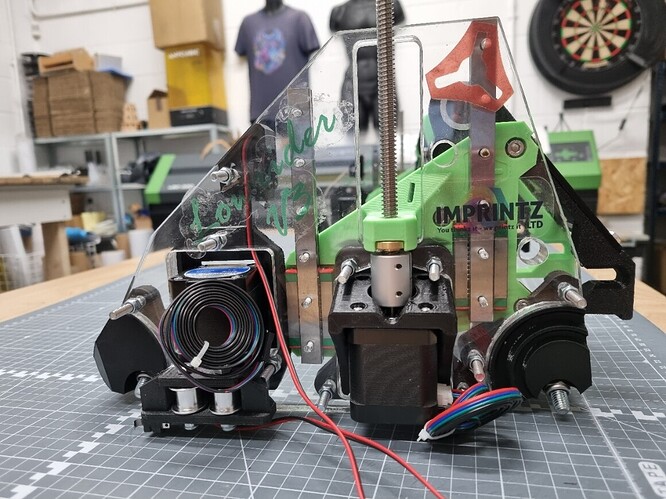

a bit further need to chang the lowride sticker as not very visible oh well good job I run a print shop ![]()

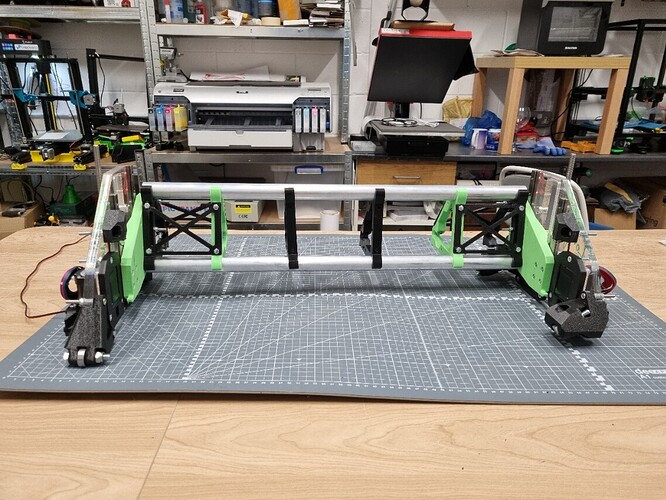

oops think I’ve lost something

almost complete.

Next step locate the lost part run the belts and then start on the electrics.

well its built . really strugling with the electronics. flashed it with the corect fimware swapped the power supply and puchased a new board with drivers but still hurting my head currently at the stage where on the screen in marlin mode if i press X to move eitheer 10 or 100 it moves 1 click and gives the error Driver eror printer halted please restart.

Do you have power to the MOTORS part?

Post some pics of your board wired up and we’ll see what else could be the issue.

yay we now have motion next job tidy all the wires up and figure out how to set this z prrobe.

Looks great with the acrylic!

What is your workarea size?

just cut my spoil board 21.5" X 48"

Hit another barrier ![]() when I try and home z only one side works and doesn’t ecognise when it activates the end stop.

when I try and home z only one side works and doesn’t ecognise when it activates the end stop.

I’m pretty sure I read somewhere @jeffeb3 said not to home Z?

any help will be welcomed ![]() )

)