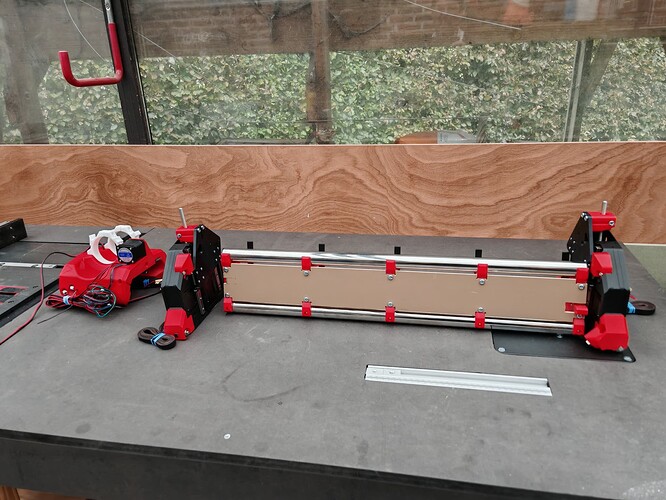

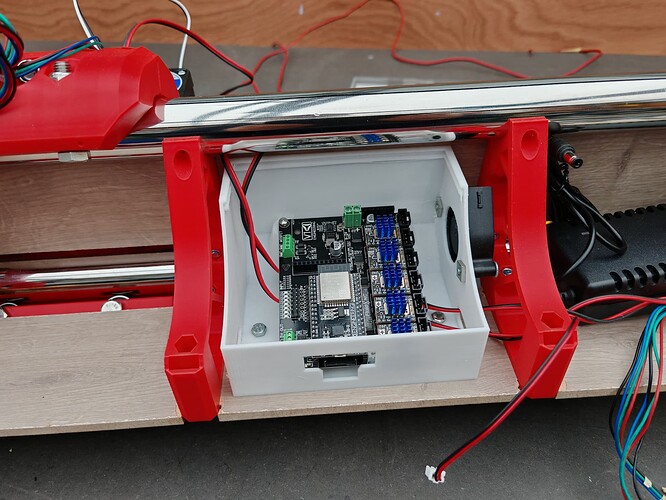

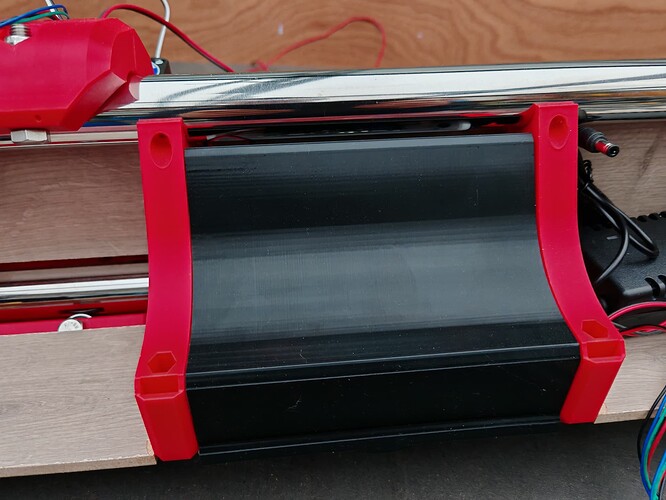

Hi everyone, I’m 66 years old and retired and I am from Belgium. I love woodworking and have just started making the Lowrider V4. So far, for the moment no problems to report. Everything is printed perfectly with my BAMBU Lab A1 3D printer. I handmade the strut plates from leftover 7mm MDF floor panels. Big thanks to Ryan and the team for making this possible.

Welcome.

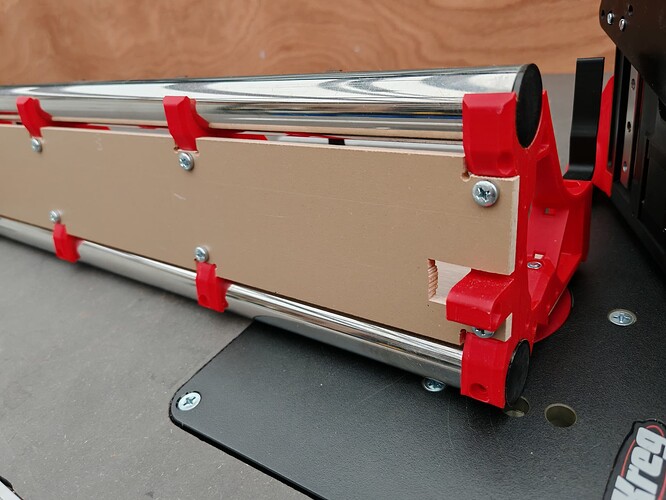

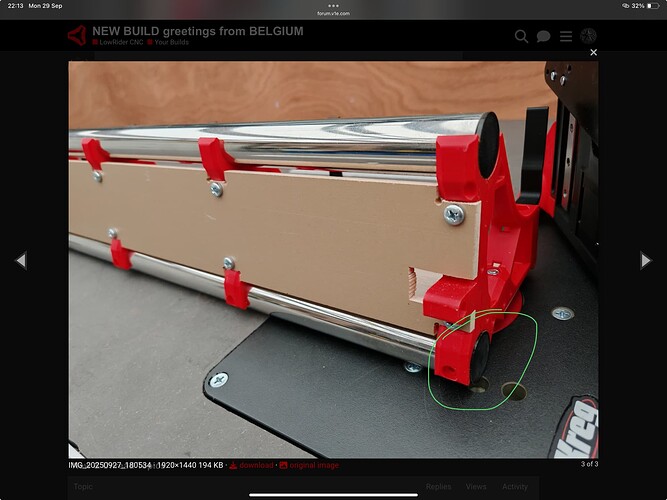

Be sure that your tubing doesn’t touch the end plates when you attach them or it may skew them and prevent the machine from being squared.

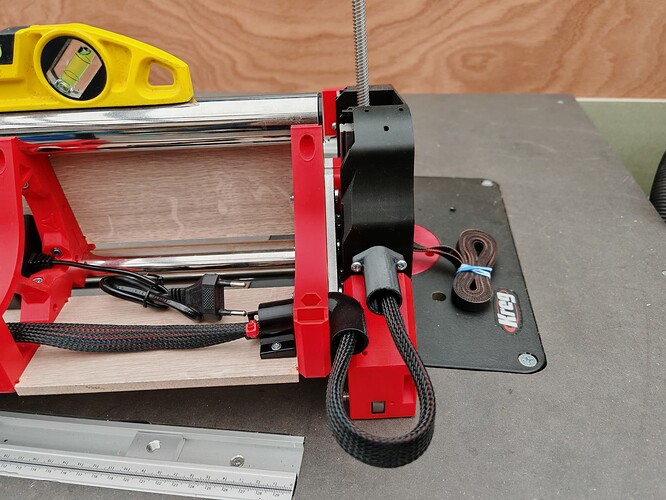

It also looks like you’ve 3d printed the plates which are intended to be aluminium - are you going to use those temporarily to mill aluminium plates?

Hello, and welcome to the V1 community forums.

Nice start on building a LowRider.

Some questions and observations for you:

Did you hand-cut your strut plates? If your woodworking skill is good, this will be fine, but it’s difficult to get those right if not CNC cut. I see dogbones in the notches, so I think it was CNC’d but want to be sure.

I note you have caps on the tubing, we have to be sure that the tubes are inset slightly from the end braces and that nothing protrudes. If there is a protrusion, it will cause toe in / toe out problems when mounting the YZ plates to the beam.

(I see @Dreyfus already noted that and the printed XZ plates. I also hope you plan to mill your own plates after assembly. Those and the strut plates are each massive rigidity improvements and you realy want them)

Once more, welcome. I’m looking forward to seeing more of your build!

Man, those rails are shiny, looks great so far. ![]()

I can suggest your friendly, licensed, neighbourhood Aluminium plate dealer to you (which is me):

Nice I also just started! But I’m in Chicago! Welcome. What a fun project!

Many thanks for your response, I will keep a close eye on the stainless steel tubes with end caps so that they do not go past the brackets and someone from the family will make the xz plates in 6 mm aluminum, which will be ready tomorrow I hope.

Excellent. Please ask any questions you have and I’d love to see what you make with your machine!

Thank you very much for your reply. I printed the strut plates on paper at a scale of 1:1, then glued these papers to the floor panels and drilled and finished them. Everything fit perfectly afterward without any further modifications. If this doesn't work out, I'll modify it later and make it with the CNC.

Thank you very much for your response. I have a family member who can make these for me. If they are not right, I am glad I know you and can contact you later.

Thank you for your message, I also wish you the best for a perfect build.

Thank you for your kind message. I am very happy to be in this forum. As a beginner, I will certainly benefit from it.

Are you using pre-formatted text? The message does not wrap to the next line, so we need to use the scroll bar to view the whole paragraph

Your posts are displaying very oddly - are you using an app of some sort?

Thanks for your message. I’ll enter the text in a Dutch-to-English translation editor and then copy and paste it into the reply editor (now I changed preformatted text in the reply editor).

Another common thing that happens is if you start a line with 4 spaces (a common thing to do) it thinks that is preformatted text.

Looks great. Please keep the updates coming. We love to see builds making progress.

Nice, that little guy should be fast!