This post primarily focuses on the needle cutter, as the upgrade from LR3 to LR4 went very smoothly. I did encounter a minor issue with both the Y-axis pulleys slipping a few days apart, but nothing that a little Loctite couldn’t fix. But I digress!

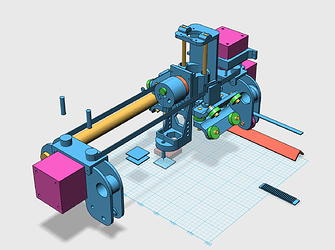

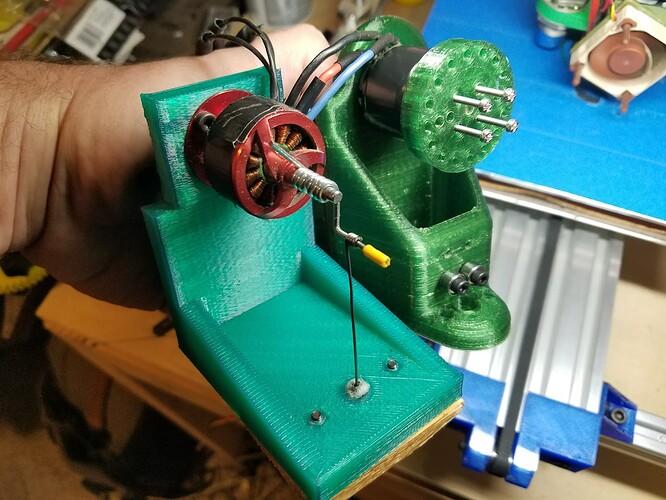

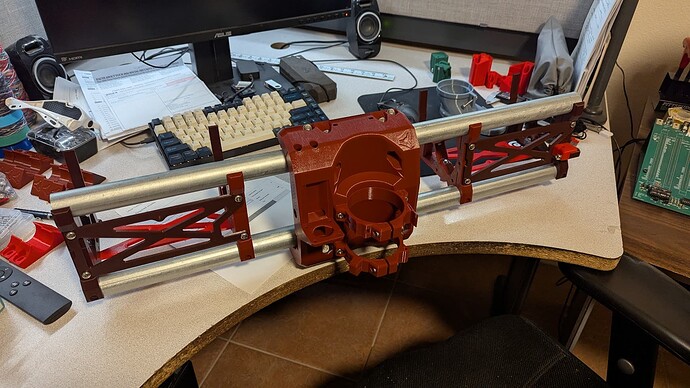

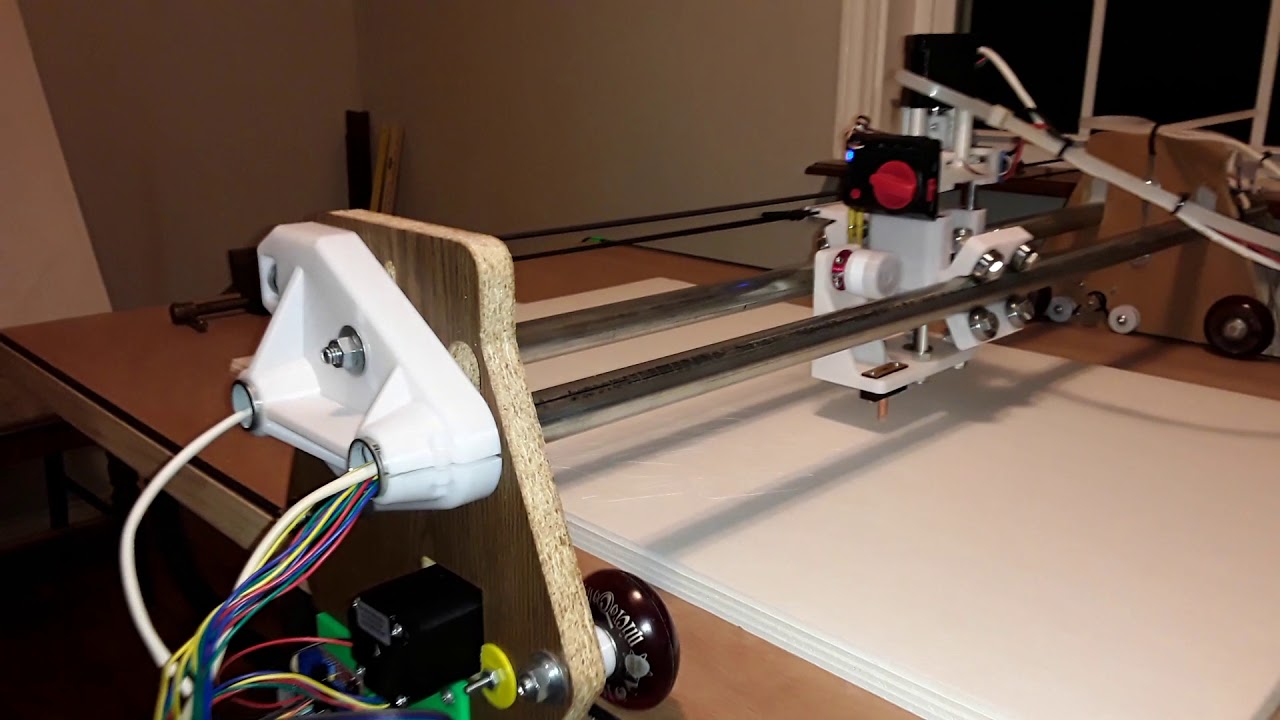

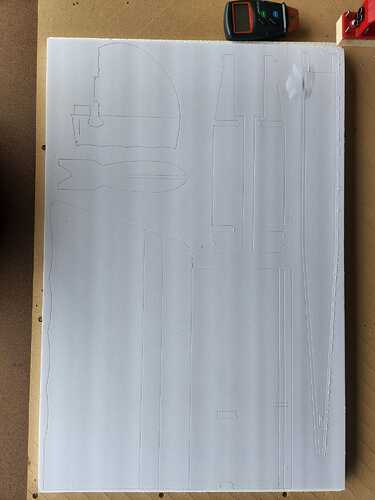

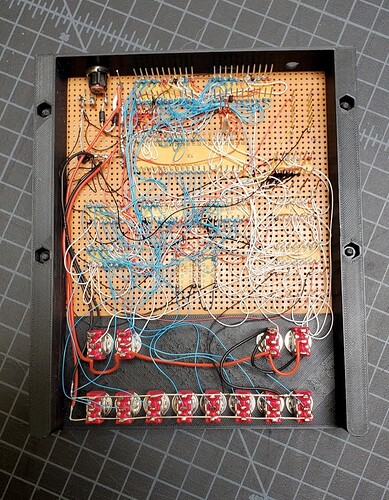

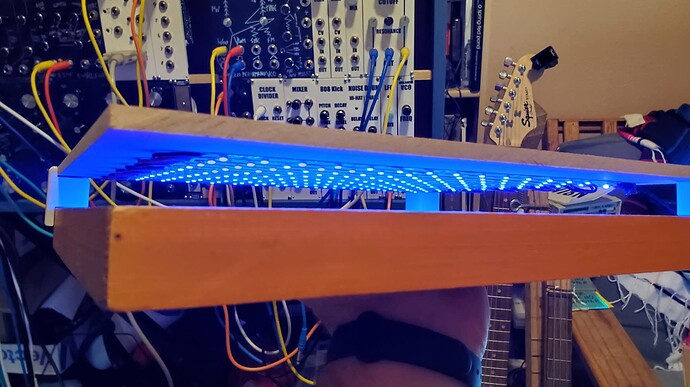

For the needle cutter, I mostly used the @jhitesma design, with a few modifications to suit the hardware I had on hand. Specifically, I used a 1mm steel wire (cable support from a Voron build), motors from a drone, some old bearings, and an ESC with a knob to control the speed (ESC on Amazon). The rest of the components are 3D printed in ABS. The setup worked quite well, and I was able to cut out a FliteTest Storch plane in about 2 hours, broken up into 20-25 minute sessions to allow the needle to cool down.

The setup is powered by a 12V 920KV BLDC motor (Motor on Amazon) that spins a flywheel at around 4000 RPM. I used a feed rate of 300 mm/min, with the needle mounted about 7mm from the center. I would like to cut the process time in half i.e. push the machine closer to a 600 mm/min feed rate.

I’m looking for guidance on improving the performance of the needle cutter. Here are some thoughts I had:

- Motor Load and ESC Performance:

- I’m using a 2212 920KV motor, and I’ve noticed that the motor slows down when it engages with the material (Dollar Tree foam board). Is this normal due to the increased load? The ESC throttles power when it reaches a temperature threshold, but it’s difficult to tell if I’m hitting that limit. Any recommendations for a better ESC or motor setup?

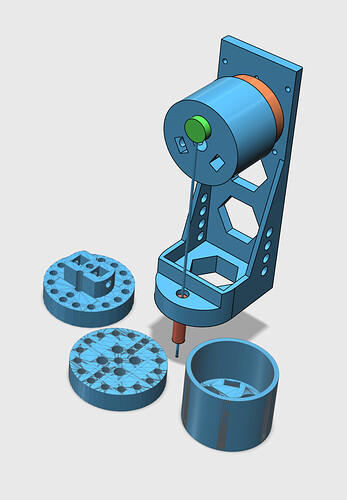

- Reducing Flywheel Moment of Inertia:

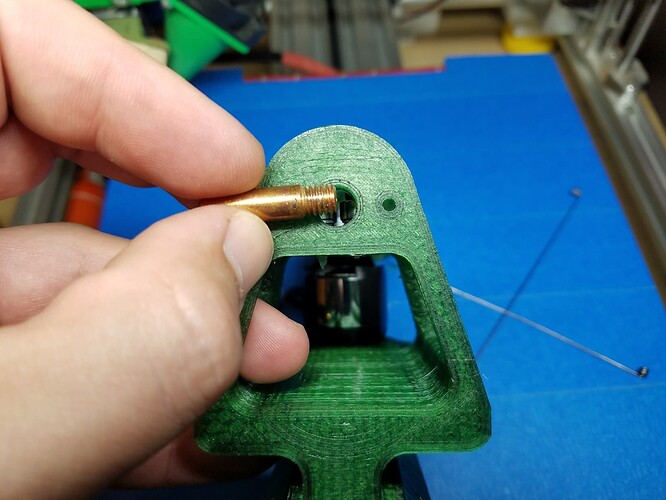

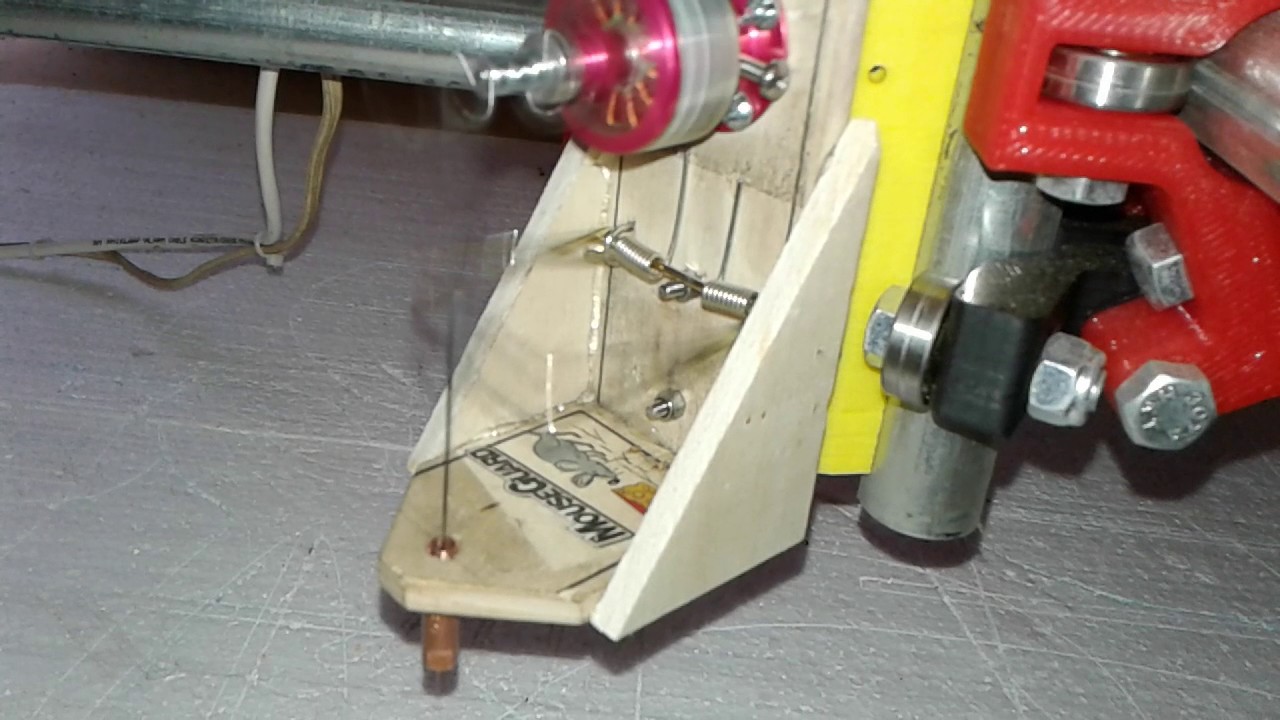

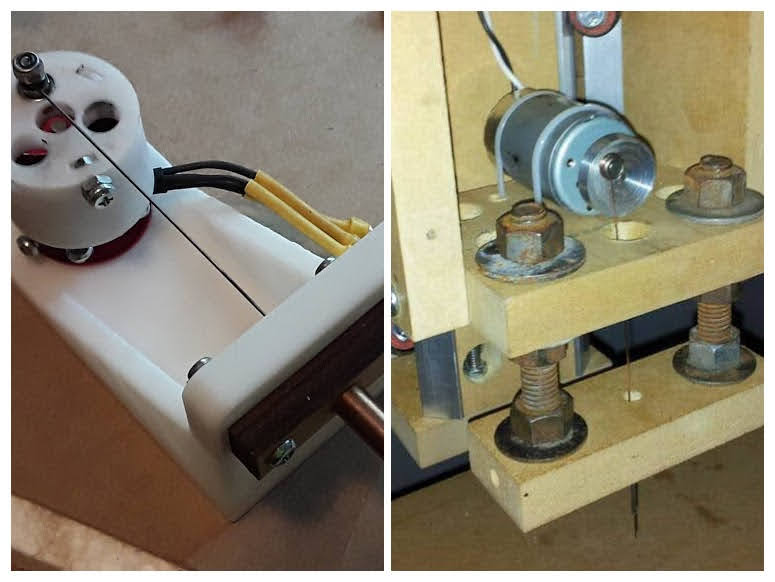

- I’m considering reducing the moment of inertia of the flywheel by moving the bearing holding the needle closer to the center. The current motor shaft size is around 8mm, and with a radius of 4mm, the closest I could mount the needle was 7mm from the center. Since the foam board is only 5-6mm thick, I don’t really need 2x7mm (14mm) of travel. Is there a way to mount the needle closer to the center, or would it not help much even if I manage to do so?

- Bearing Size:

- I’m currently using a 10mm OD bearing (Bearing on Amazon) for the needle. I have a suspicion that it is generating a lot of noise which can’t be good. Do you have any recommendations for a different size or a better alternative?

- Wire Thickness:

- I’m using a 1mm thick steel wire, and I’m wondering if that’s causing too much friction with the MIG tip. The needle moves freely by hand, but might a thinner wire reduce friction and improve performance?

- Lubrication:

- Would adding lubricant to the eccentric bearing or MIG tip help or hinder performance? This setup is high-speed rather than heavy-load, so I’m concerned that lubricant could introduce drag, especially given the small clearance in the guide. What are your thoughts?

- Heat Management:

- The needle and sleeve heat up quite a bit during use. I’m considering soldering a metal plate to the MIG tip to help dissipate the heat. The plastic parts are insulated by the wooden block, but I’m not sure if this modification will help the performance.

- Needle Retraction:

- I’ve read that the needle should fully retract inside the guide during the upstroke. Does this actually help in any way?

Let me know if you have any suggestions or advice on these points. Thanks in advance for your help!