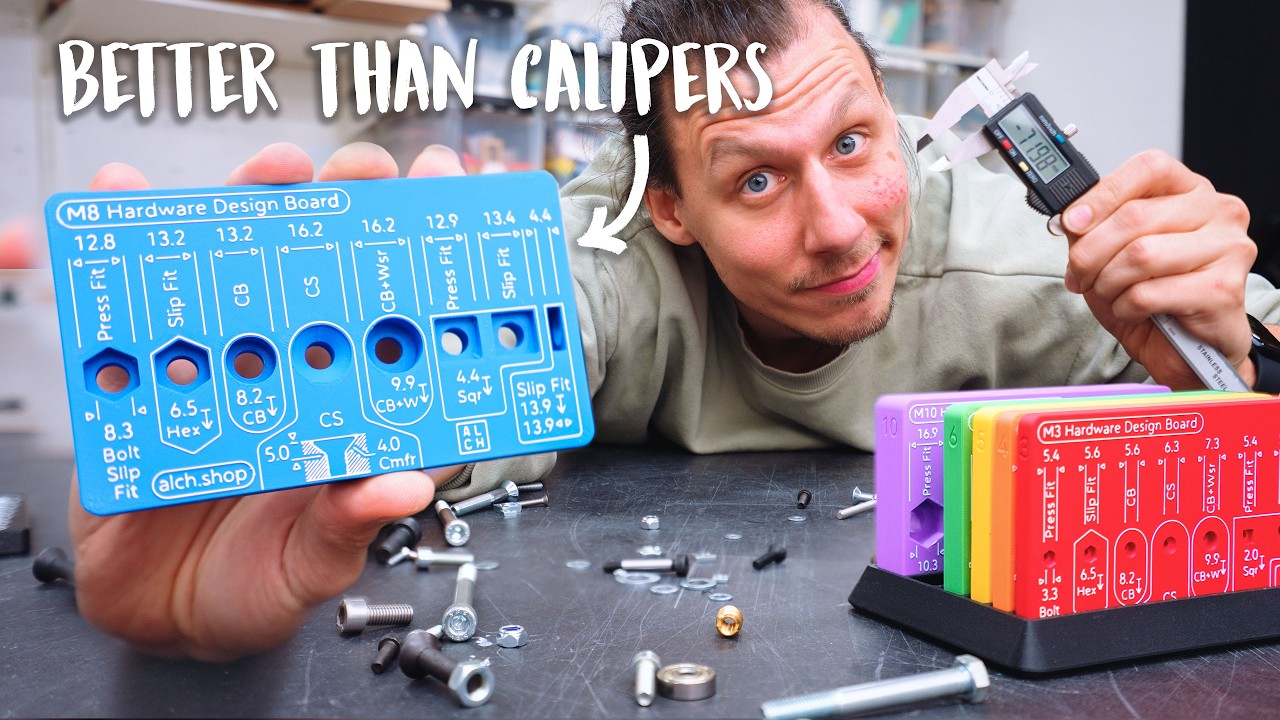

These are pretty cool.

If he could make a design board for embedding, slip/press fitting 3d-printed parts into each other, I would be even happier! Each time I’m making something where I have to figure out tolerances, I always forget them and have to redo my attempts. I guess such a board would be difficult, since all printers have their own personalities and quirks.

The onshape holes tool works pretty well for the hardware I have made so far. But I haven’t gotten too complicated. I have also seen several kinds of bolts that are wildly different. So I am not sure if there is a more complex bolt spec or just imprecise manufacturing.

I really like the hole grids though. I also liked to see the Swedish guy politely tell me that Imperial bolts are a dumb system. They definitely are archaic.

My rule of thumb: If you want a “push” fit - make the parts overlap and subtract one from the other using a Boolean function with 0.1 mm clearance. If you want a sliding fit, use 0.2 mm( remember this is almost half a mm of slip, so it’s sometimes better to go smaller and work the joint a little.

Success depends on using the same filament for both parts!

And the same printer if you have multiple

During my search for a brass gear I had the idea of making a mold and casting it… And guess what, someone did this with a 3D-printer. There is wax filament… Whaaat?

I have had some success with just using pla. But I did check out their website. The wax is about the same cost as Polycast’s lost wax plastic. May have to try it out

I use to use Machinist hard wax ‘and still do’ in some builds. Pour in blocks and then mill out. Good for making detailed molds. Melt and reuse.

Yes the mini foundries are fun !!!

I built one haven’t had much time to use it but it is the season now.

A lot of ppl just use pla and burn it out. Apparently they get decent results with that.

Drinking beers and melting beers is kind of fun but holy moly lots of chemicals.

And idk why but it’s so satisfying making mini aluminum cupcake ingots.

OMG!!! I want to see someone make a Brass LR4!!!

I think the parts have too many undercuts and such so they are not castable.

Do you have a crisper kit, and what’s your ethics for fish specifically lol.

Totally joking and yes something has to be done.

It’s so bad overseas in places that don’t have paper or wood readily available.

thats the beauty of it. Lost wax method is one and done. Print it then coat it in you casting shell, add the spue’s and vents in proper places. Bake the shell, pour the metal. Break away the casting shell.

Oh great point. I only has to work once and we can make another mold.

Nice pic!

My reaction to this video was to write my first onshape feature script. It adds pockets for nuts I regularly use. I’ve been adding hardware/nozzle size pairs as options as I use them.

Don’t… give in… to the temptation…

![]()

![]()

This is the stuff I need to be looking for tutorials on lol. But most of those you find you have to already know how to do it to understand what they are saying LOL

You can do it Phil, you’re stronger than this!

Yeah, I found that to be very true of the feature script language. I frankly do not like it at all haha but once I got the hang of it I’m not too afraid of writing new ones.