I could definitely use the feature that adds the little multiple hang overhangs on nut holes like in the video (although I first saw this many years ago on the V1 STLs).

Oh that’s a good idea too. I like to have one layer go all the way across where the bolt goes through if the nut hole will face down so that it just bridges across then it easily punches out. I think I’ll add that to my script.

Not sure if anyone is on facebook, but this is a really wild machine! https://www.facebook.com/reel/1590840835184489

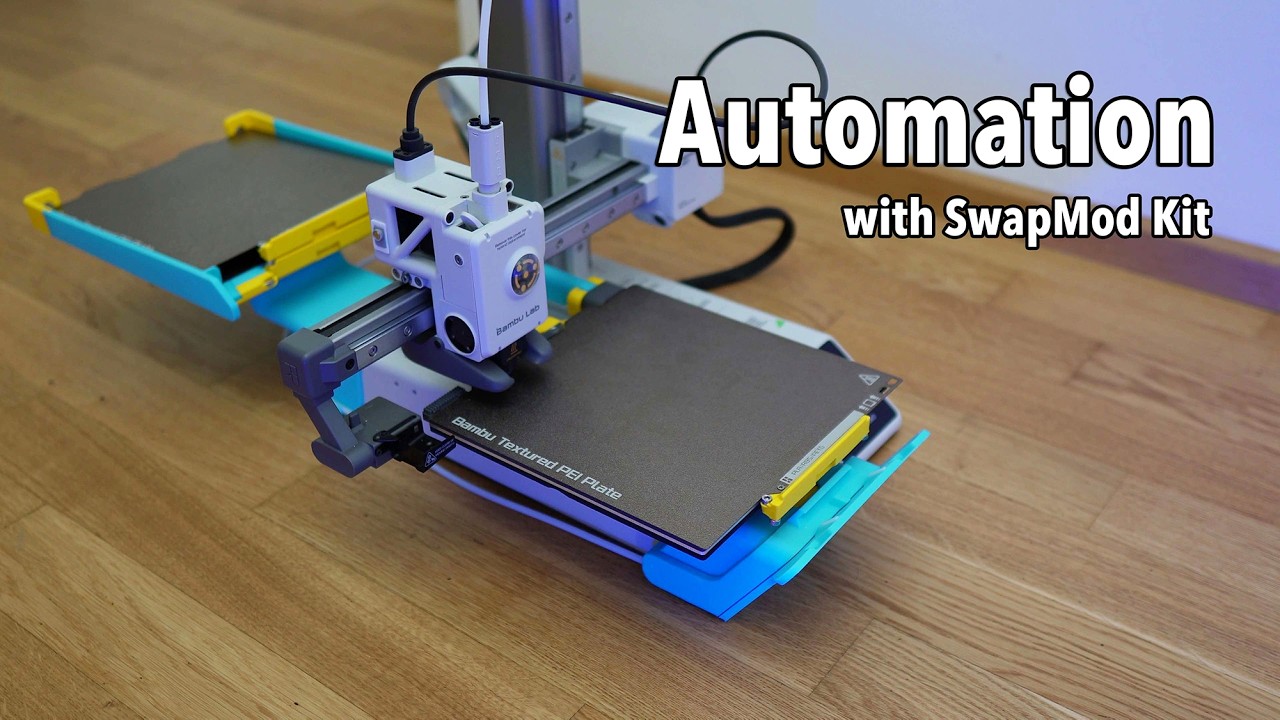

This us a neat “infinite” build plate system. This one is very polished and targets the A1 mini. It specifically works because it is a bed slinger. But I thought it was clever. The web app seems smart too.

6:30 or so is where a cool test works.

That is slick!!! I was thinking the other day that a belt printer could print my lr 4 strut 4 me ![]()

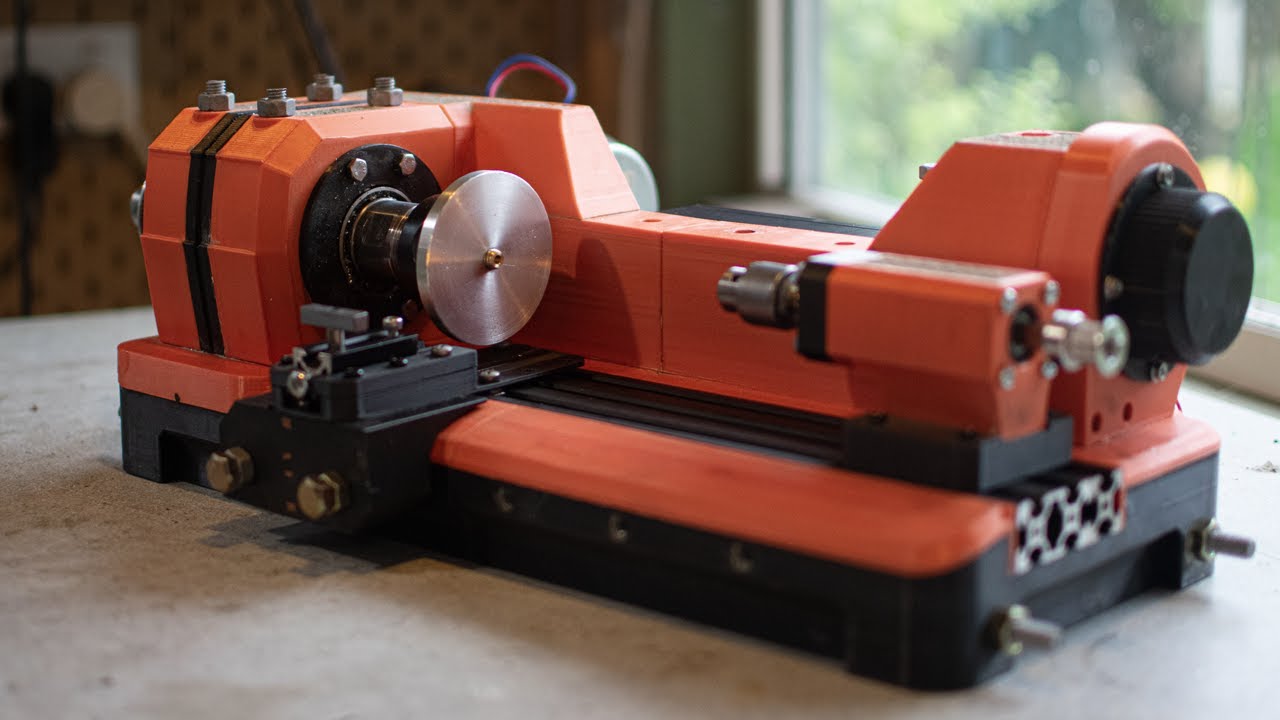

This is a super cool idea and has pretty reasonable performance. There’s still a long way to go in terms of needing an actual carriage and cross-slide, but it’s a pretty good start. Anyone know a guy who does stuff with cheap DIY motion platforms? ![]()

Could also be combined with something like a DIY version of the Eccentric Engineering Turnado hand turning tool and some 3D printed or CNC routed profiles for the tool to follow.

I’ve always been fascinated with the approach of using 3D printed parts to make molds for casting metals etc. but hadn’t considered that it could be used as a mold to be filled for casting bigger structures. Amusingly, I’d seen a design for a kettlebell that was a plastic mold that was intended to be filled with concrete for weight and thought ‘I’m sure I could 3D print that mold’ but hadn’t actually thought about it for anything other than shaped weight/ballast kinda things.

Haha, i just saw that on reddit! They filled it with concrete!

He was using handheld tools!

Wow, that video was much better!!! Wonder what the other tools were in the video, one was a press for the captured nut!

Need to get him in here so he can collaborate!! His other stuff is cool too!!

That is very interesting.

I originally got into the MPCNC brcause I didn’t think I could afford to throw money at a CNC. I don’t have any intention of making money from that machine and even cheap kits were $3000 or more at the time.

I feel like this could be the lathe that fits that same spot for me. I don’t have a lathe. I know cheap ones can be bought at harbor freight or alibaba. But I would rather the shortcomings be from me making it that just buying trash in a lathe shape.

Lidl in Germany has a pretty okay store brand called Parkside. I bought a 79€ lathe from them, it is really okay for that price.

We had one of those cheapo ones at work a small thing and it couldn’t even be used on plastics.

The old big heavy ones are the best. You can check at government auctions. They sell them regularly.

I think the 3D printed one is cool and I like how he did the concrete inside. A lot of the diy Cnc use granite and epoxy for resonance and weight iirc. That lathe imo is very similar to a drill and a angle grinder haha that’s my home lathe.

I don’t even have a project in mind. Besides maybe some pieces for pub skittles. But I could probably do those on a drill press too.

The motivation would be to learn about casting with concrete and having some kind of lathe I could use to see if I liked it.

I’ve been following Chris Borg for some time - there are a couple of his other projects in this thread. I like that he is young and has a different take on things to the usual suspects. His vice is a finalist in the Printables contest too!

I literally have nightmares thinking about how I would keep this working. It’s cute for a demo, but outside of that forget it.

Yeah, the lathe aspect to it is almost secondary to why I posted it. It’s more that it’s another way to make 3D prints rigid/structural in a remarkably cheap fashion.

I also tend to disagree with the ‘just get a proper one’ approach when it comes to machine tools. Smaller/cheaper options definitely have compromises that make them less capable than their ‘proper’ counterparts but isn’t that the entire philosophy behind the MPCNC/LR? It’s not a do-all machine, but it’s accessible to a larger range of people and cheap relative to its capabilities…

Yes the infil is a cool idea for sure.

Just trying to add my personal input.

Something like this one here is terrible for instance and is a different kind of fill

Land fill lol

I have difficulty believing that something like that wouldn’t work with plastic or light cuts in aluminium. Is it potentially an issue with the tooling being used? Or some other issue like an actual manufacturing defect, gibs not being adjusted, that kinda thing?

I don’t have any experience on a lathe that sized but I do have a fair bit with my Dad’s import 8x20 lathe and the single biggest determining factor on those smaller machines seems to be the tooling.

Edit: I guess the main issue is that cheap/crappy machine tools are most likely to be bought and used by inexperienced operators which is going to create a compounding effect on the results that the machine can produce. A machine that isn’t particularly rigid to start with being used by an operator that doesn’t know to adjust the gibs or to lock the axis not being used along with a blunt or straight up incorrectly ground HSS tool is always going to be a shit-show, but only ‘some’ of that is the fault of the machine. A much bigger and more rigid machine can likely produce something that’s more usable under those situations, but it’ll never shine.

Trq is it’s major issue you can spin it up full speed and just grab it and stop it with your hand.

I am not sure that this one has any serviceable items.

I am definitely not a machinist by trade.

I am sure you could widdle away some balsa or make some very small passes but again. A 1/2” corded drill mounted on a table would have been better than this little guy at work.

The older lathes can be found for fairly cheap. Today one was a hour up the road 12’ bed old one. Actually maybe a bit too old but 1600.00 cad.

While we are on lathes, I will add something that is DIY and neat. I want to make one for our other crappy lathe lol.

A burnishing tool https://youtu.be/AihbaosrLS4?si=aUvrkx9YRNBD9zgr

Well, now I want a rotary axis. https://youtu.be/7mvLTeJ27ww?si=d8b1Ncfvxu1udjl-

Ican say the only thing stopping that here is cam!!! I think this hive mind could make an awesome machine!!!

For free gcode ripper from scorcworks

https://www.scorchworks.com/Gcoderipper

And vetric vcarve pro and aspire will do it also.