A little while ago there was a post that featured a video with a cnc cut foam pattern for lost foam casting, here’s another and this guy REALLY takes it to a whole new level. Just brilliant!!

https://youtu.be/BoPSllYj0Dw?si=0_TSuaPtLtLVSG5L

BTW, how do I insert a video like Barry did in the previous post?

Haha sweet I was bidding on a trumpf laser a while back. Man you can grab them cheap if you have time to wait. I wasn’t sure about the drivers tho so I didn’t get it ![]()

Just found this on my daily HaD visit. Link is to the original Youtube video. A WIP to-be-open-sourced modular multi-filament printing rig.

wow, that is awesome!

way more than I ever want or need

Architect’s perspective on FDM concrete housing. I thought it was compelling. Some interesting perspectives:

- It is similar to brick. I hadn’t really made that comparison

- You can’t change anything once the building is finished. This is a good challenge for future mechanical engineers.

- The machines don’t like working on top of human tolerances. He sort of talks about tolerances but only describes how inflexible the machines are, not how much more precise they could be (or are).

- Having a 3D printing mistake visible for 50 years sounds awful.

What I think is interesting about them that wasn’t talked about:

- FDM makes a new paradigm in design. Similar to how people printed out emails when it was first becoming popular. You don’t know how things will change once you have a new way of thinking.

- Moving problems into software makes scaling easier. Crudely, I think of thingiverse and customizer. If you can improve design and then have the machine build to the software’s specs, you can design spaces in a whole new way. I don’t know how realistic that is for custom homes. But commercial buildings or workspaces could really benefit from a DIY design process and a 48 hour builder. This is a big way it is different to prefab housing or modular design.

- These buildings really seem like they are trying to do the same thing we currently do for cheaper prices and faster speeds. But walls don’t have to look like that. If this was common, I bet there would be different techniques that will make them look different. Imagine having much thicker walls. Or having a “tool changer” that can insert utilities or threaded inserts at specific, precise locations. You could have a completely different space than 2x4s could build.

- Concrete has sustainability issues. If this was made from mud and hay, I could imagine completely demolishing a restaurant and rebuilding it when a new company moves in. It’s not great to think about buildings as paper towels. But it would be possible.

That is funny, I watched that one this morning. I kept thinking that ain’t right, but…

Really made me watch with a more critical eye. Brick sucks to repair…but it can be repaired. I have no idea how this would get repaired. From there I was way more receptive.

I like your thinking though. Maybe these aren’t generational houses, so maybe a major incident is as easy as pulling out some modular stuff knocking it down and reprinting it all. We think of these as traditional built houses, but they are not. Maybe in 10-20 years we get the wall recycler machines to crumble these up add some binder and reprint.

OK as a “once were architect”: - This is not an angry rant, although it certainly will look like it!!

I think they are appalling in the same way that container houses are.

They are a great idea something akin to geodesic domes in the 60’s and 70’s, but the concept is seriously flawed. Flawed new thinking is no different to flawed old thinking.

Forget about all the other arguments (including yours! ![]() ) these are NOT 3d printed houses, they are 3D printed walls, which still require things like windows, doors, wiring, floors, roofs, ceilings and cupboards, and the construction method makes fitting of all of those components more difficult.

) these are NOT 3d printed houses, they are 3D printed walls, which still require things like windows, doors, wiring, floors, roofs, ceilings and cupboards, and the construction method makes fitting of all of those components more difficult.

Walls are pretty much the easiest and most economical components of a building to construct, and are usually the most adaptable for future usage changes over the life of the building.

3d printing solid concrete is a kind of built-in obsolescence a bit like the Nakagin Capsule Tower in Tokyo, sadly now demolished.

The simplest and least labour intensive way of building concrete walls is to create “tilt” slabs - pour them on a floor and tilt them up when cured.

That people are seriously proposing the least eco friendly material as affordable housing in areas where the one commodity that is readily available is labour, is a bit proposterous really, this is the one time where any other material is better!

I’m happy to go on point by point, the tech is cool, but I’m a definite naysayer!!

but Switzerland is nice… ![]()

Oh yes, but that would mean a roof and ceiling that could lift off to give the printer room, and some method of removing and replacing services in just the affected areas.

Bah! Horseless carriages will never catch on!!

So in america i think unions have a say in this as well. YOU ARE GOING TO put US OUT OF WORK! But in reality need to just figure out how to work in a different way. It will all come around.

I lived in a world without internet and microwaves.

Now look where we are!

But as said, need to watch obsolescence!! Look at all the buildings walmart walked away from. We get to a point where rebuilding means it is cheaper to build new, then we have a major problem!

I think that until two things are grappled with effectively, 3D printing terrestrial structures at scale will continue to be a novelty.

- Materials Science. Concrete is not really viable long-term, either for the structure, or the environment. We need to develop materials that can be stable, insulative, and reusable within a reasonable cost envelope.

- Design Horizon. The Buckminster Fuller/Frank Lloyd Wright factor. Designs need to evolve to better incorporate the technology better, and that needs to spread to the supporting infrastructure (plumbing, electrical, HVAC, data, lighting, security, etc.)

Until then, we’re just using fancy toys to make the same walls we make today. We’d do better to either make tilt castings as @bitingmidge described, or pre-fab’ing stud and drywall construction (which can be helped greatly by technology via CNC).

I specified terrestrial structures because I think there is a use case for automated, regolith-based printing of structures in-situ in space, regardless of materials or design progress.

I will forego my rant on incorporating eco-friendly (e.g., “Earthship”) features into designs, as it is beyond the scope of the conversation (at the moment). ![]()

I think it’s a great idea especially if you mix in vermiculite and maybe some hemp.

Make hemp Crete for the fire prone areas. Especially out buildings and things like that. And I mean the layer line walls wound be pretty easy to add onto I think. It’s like a serrated edge already.

Plus you can literally have this setup in some remote area and all you have to worry about is feeding the machine.

It can work near 24/7 so production would be fast and great. I mean look at the cinder block houses and also this new styro foam block houses with concrete in them.

Just put lots of extra conduit in for the electrical and possible expansion.

The add water concrete buildings that inflate are also kind of cool.

Also you can have a set of plans verified and checked out per code and just hit print lol.

Especially good for places that don’t have lumber handy. Like my time in Sudan everything is made of concrete. They don’t even have wood for forms.

Ohhh and pools and hot tubs etc it would be well suited for.

Oh and pizza ovens, or ponds.

These are all excellent points. But my biggest problem with them is that you are thinking like someone who designs buildings the way we do right now. The power isn’t in building concrete buildings. It is being able to make a design in software and have a robot follow the plans precisely.

We live in a world where the same dishwasher is installed in Australia and Europe and the USA. So you could make the argument that 100x the flexibility is not valuable. But using this technique to make a flat wall is exactly the same price as making a curved wall. And as the technology improves, it could be made to make built in textures or art or functionality or something architects haven’t considered. The power is in the software, not in printing rectangles.

Edit: In general. You’re right. I reread it and it looks like I’m disagreeing. But I’m really just trying to converse.

I have that on my wall lol

But I have something that I feel is NEAT

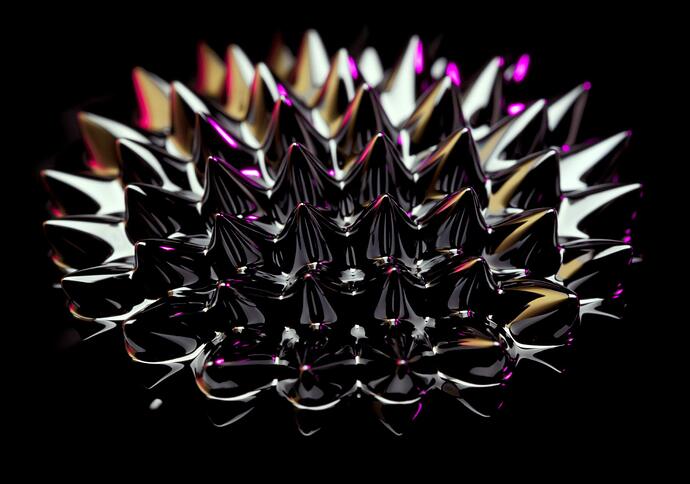

Can we talk about ferofluid ?

Has anyone added some to their routers in here by chance ?

I have tried to buy it twice now for my quad bike, that really doesn’t need more power.

Speak now!! ![]()

Well apparently back in the day ppl used to add iirc atf trans fluid to hub motors. And this would help with heat dissipation and spread out that heat over the whole are.

Now there is some fluid you add into motors of any kind iirc and it’s a pretty thick fluid and has some form of ferrous particles in it. And you literally inject it inside motors and it goes to the outside stator magnets. And basically fills the gaps and and makes for a pretty perfect coupling of said stator magnets to the outside housing. Allowing for a lot more power to be made safely. Usually ppl would add extra heat syncs to the outter casing as well.

Basically a big maintenance upgrade for any motor.

It also serves as a visual of the magnetic fields.

There is a beach near me that we call purple sands bc it has so much iron mixed in and the sand does the same kind of thing with magnets.

There’s also a machine that grinds up pavement, injects new asphalt to the grindings, and lays it back down. Pretty neat system.

They are doing that right now in our town but having to fix underlying problems also so more time

We got to watch that machine work in front of our house a few years back. It looks like a dinosaur.