I love that my carpel tunnel would be muxch relieved ![]()

Yeah is a neat setup for sure. I went to his website to see about the parts. To order the 2 boards and the motor setup from him is $200. Higher priced than I can justify for the amount I solder.

Am I the only one thinking “Carbon forged LR3 parts” ? ![]()

Appart from being cool and probably stronger than PLA parts, this would also allow for easier batch production for @vicious1 , wouldn’t it?

Maybe not for every part, but for strut braces, core, even maybe YZ plates?

A more in-depth look at how this can be applied to production process for small batches

That “forged carbon” looks cool and all, but it risks loosing all the strength of the carbon fiber. At worst case, it’s the epoxy resin with some CF floating around in it, which means it’s as strong as the binding resin. To get the best results, you’d need a lot of pressure to get to the optimal resin:CF ratio that keeps everything together without flaking apart, but can rely on the CF strands for strength. There’s a reason Lamborghini patented (trademarked?) forged carbon fiber… And why it isn’t the norm for production vehicles (as if Lambos are “production” vehicles).

Totally agree on the “cf-like-rigidity” lie

Just like “cf filament”…

You can get some of the rigidity bonus by laying long strands in the right direction across the part rather than those munched pieces through…

Anyway, “press-molding” those parts could still be benefical and stronger than printed parts (think about layer-adhesion problems…) although I think the munched cf bits could be replaced with eg fiberglass without significant difference in strength, as most of it probably comes from epoxy

Yo Cummins, this you? Were you hacked? ![]()

What? I’m not all non-sequiturs and double-entendres… I actually have some serious thoughts and comments.

I did the forged carbon handle it was a lot of fun. Was actually pretty strong as well.

Plates and struts I think…

Also, for producing parts for sale - and for the LR3 core in particular - being able to cast the part in one go rather than gambling with a 12hours print each time could be a great bargain too (even if the part is not a lot more rigid than the printed one)

And you have to admit those look super cool!

Just imagine a full-carbon-forged LR3, complete with @bitingmidge’s fenders! ![]()

That thing would be a pain in the ass to mold, and demold.

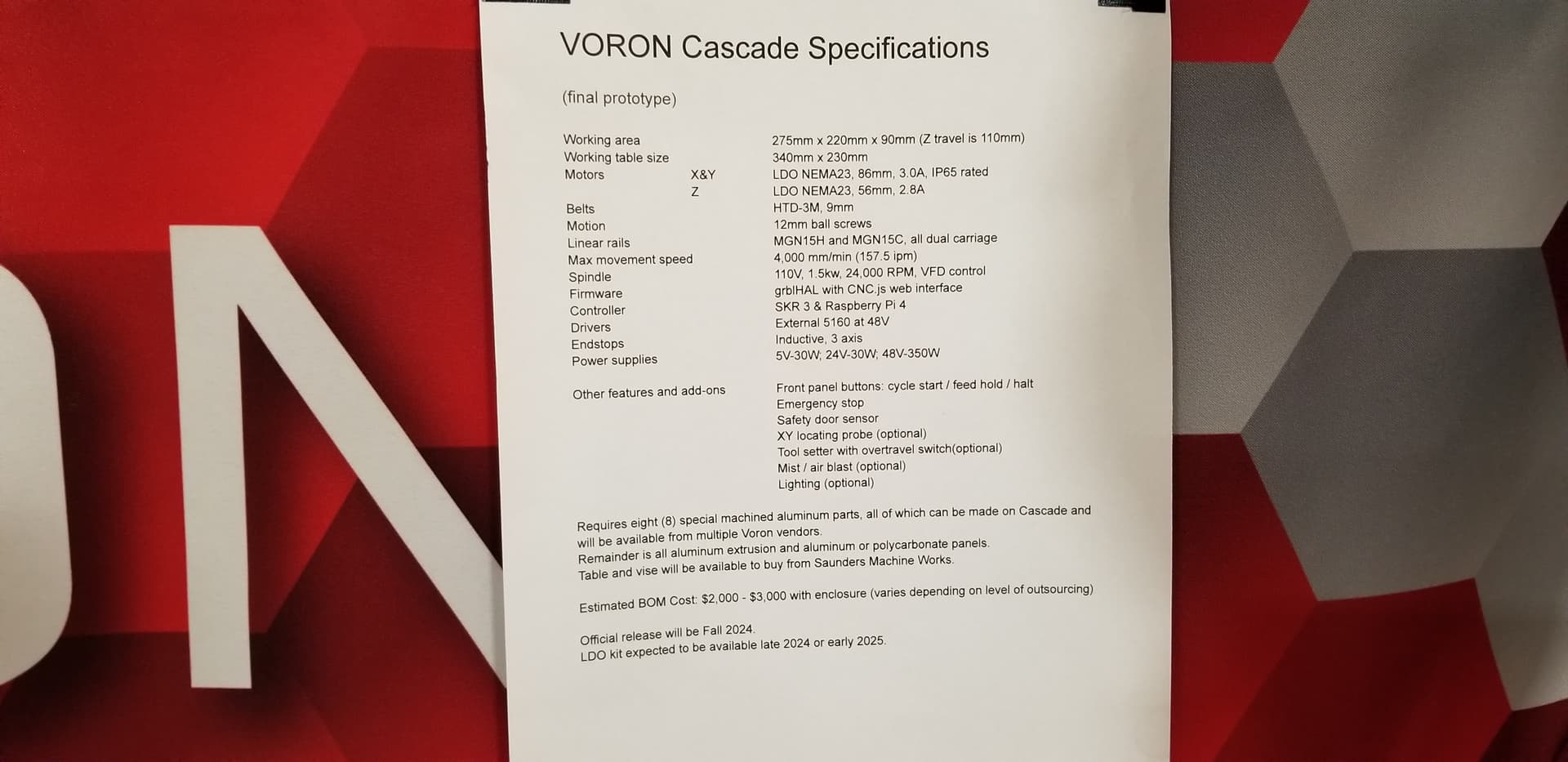

Looked like a hulked out Genmitsu 3020 to me, looks neat for small-medium sized M3DP, CNC and other parts. Interesting to see how cut cost/performance compares e.g. $$$/mm^3/s dollar per MRR.

Yeah agreed, in the video Doug says its ~$3k and hopes to maybe get it in the $2k with kits at scale. That is a lot of money

How stiff is a small LR3? Let’s say small is about 8" working area.

It might look bulky, but as far as performance and cost, I would think it could hold its own.

With ball screws and/or something that captures gantry, instead of just using gantry mass * gravity?

https://www.amazon.com/gp/bestsellers/industrial/350657011/ref=pd_zg_hrsr_industrial

That’s possible, but I was thinking the identical design, just small. The video claims aluminum, brass, and maybe steel under some conditions, which we have on the MPCNC and I bet a small LR3 is as good or maybe better, since Z can be super short.

How about mounting a Nano Lightsaber (Wire EDM) that emits 10,000 plasma hot metal vaporizing arcs per sec to cut through titanium, steel and other metals like they’re butter?

I talked to these guys a bit on Friday during setup. I hadn’t bothered to see it in action, but I should have. That is really cool.