Oh yes mig and arc still have a lot of use and it’s fast too.

I say get them all haha

I went down the rabbit hole of youtube videos about people building granite Mill CNCs. I’m not so sure that’s a machine I’m ready to try to tackle yet. I think I’d be more inclined to try to convert a small benchtop mill to CNC first.

Man, hitting granite, that would be a rough one!

Most of them don’t have the actual spoilboard made out of granite. The rails are embedded in the granite or bolted to rails embedded in the granite. Then the mount plate is bolted to the rails. From what I understand, the extra weight/mass is supposed to help with vibration dampening and ringing.

yes, but all the granite I have ever seen is for Cmm, not for cnc. going through spoilboard on accident is easy.

Yes I remember reading something about the weight of the Cnc taking up the vibrations etc. I have also seen some ppl building them with epoxy and granite rock.

I love my granite slab at work for measuring and lapping.

I’ve recently been trying to TIG aluminum. It’s really hard!!! I probably should have started on steel. ![]()

I was kicking around the idea of building an epoxy granite mill before I built my Primo. I still may do it for a smaller build volume down the road but I think a LR3 will be higher on the list.

I don’t understand why they made a mold of the product, instead of just using the original board. It seemed like a lot of extra work for no real benefit.

I didn’t understand the process either until I read the video description. He shared background, intent and context there about how CNC’n a bunch of Oak plaques for band fans was less feasible than making a batch of plaques using a mold.

I bet I could make more CNCing them out of Oak rather than waiting for the mold to dry. Still seems silly even at scale

If you factor in the finishing time and material cost, it might be worth it in the long run

Plus it’s a lot more “repeatable”, wood can exhibit a lot of differences in quality and look

Also, re-aligning the part for laser details can be error prone and time consuming

However, I didn’t know a resin cast could retain such a “natural” wood grain look, pretty interesting…

You could pour into a mold and then go to dinner or sleep. Or why not pour into molds while you are also CNCing more out of wood?

Neat joint, but it appears to be relying on friction to hold it in place?

And this on a car build I’m following - just thought the exaggerated dogbones were a cool idea too and I can see in the right circumstance a lot of grief avoided.

I’ve seen this on my feed, but found it very underwhelming indeed…

At first glance I thought it was some kind of “twist-lock” joint, but in the end it’s just a friction fit tab with a shape making it more “kiddy like” I guess… well, not impressed…

Making a whole kid’s bedroom furniture with cnc’d plywood is a nice feat though

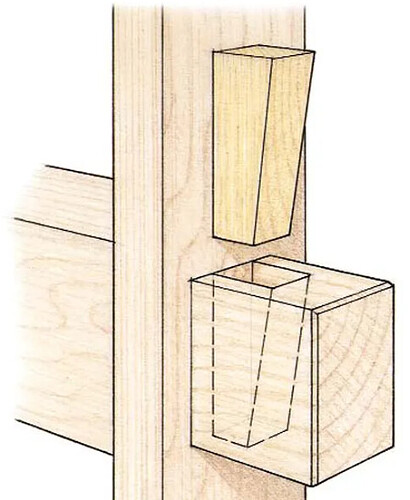

(didn’t watch) - wouldn’t youjust put a wedge in the circles poking through to shore it up like a wedged mortise and tennon shown here:

?

One would think so, and it wouldn’t be too hard to do, but as @Fabien said - it’s crying out for some sort of twist lock, which would be a whole new world fo pain to sort.

As it is, it’s just a friction fit or glue join with most of the gluing surface area removed. I like the concept, just not the execution.

I also think it looks hideous. ![]()