Well maybe this summer i can try and find out.

You need a cutting torch and grinder. Start a lot more ![]() Wife has made me throw out so many ‘confortable’ shirts and jackets because of all the burned holes.

Wife has made me throw out so many ‘confortable’ shirts and jackets because of all the burned holes.

I saw that Milo video before, and thought the same “it only cuts a napkin” BUTTTT I also had an idea to make a LR3 style gantry on a croxy set up like the primo. Belts wouldnt be an issue, but the struts would be. So it might be more feasible to make a core that takes 2 rails in each direction, then brace them off at the trucks. But is it really needed?

Livin’ the Dream

What if one side had more restriction so you get a pressure difference? Might be the same effect and easier to implement.

[quote=“Philipp, post:409, topic:7380, username:Tokoloshe”]

A living CNC Machine. I didn’t know this was possible.

That’s a really nice conclusion too - and it sums up pretty well why my LR3 is really a tool for special jobs rather than the general all-rounder it is for many of you guys.

I have the tools and experience to cut stuff by hand mostly in the time it would take to make a drawing let alone mucking around with CAM, BUT as a hobbyist the tools and experience took a lifetime to acquire and of course mostly I am happy with accuracy to the width of a thick Sharpie.

There is joy and satisfaction either way, and I suspect as my brain gets foggier and my hands shakier, automation will become more important!

On that note, we completed our tour of a couple more campuses of that school this week and last with a visit to the robotics and controls kids, and probably coolest of all - the cyber-security labs, where two teams pit themselves against each other to take control of the services in a Lego city!

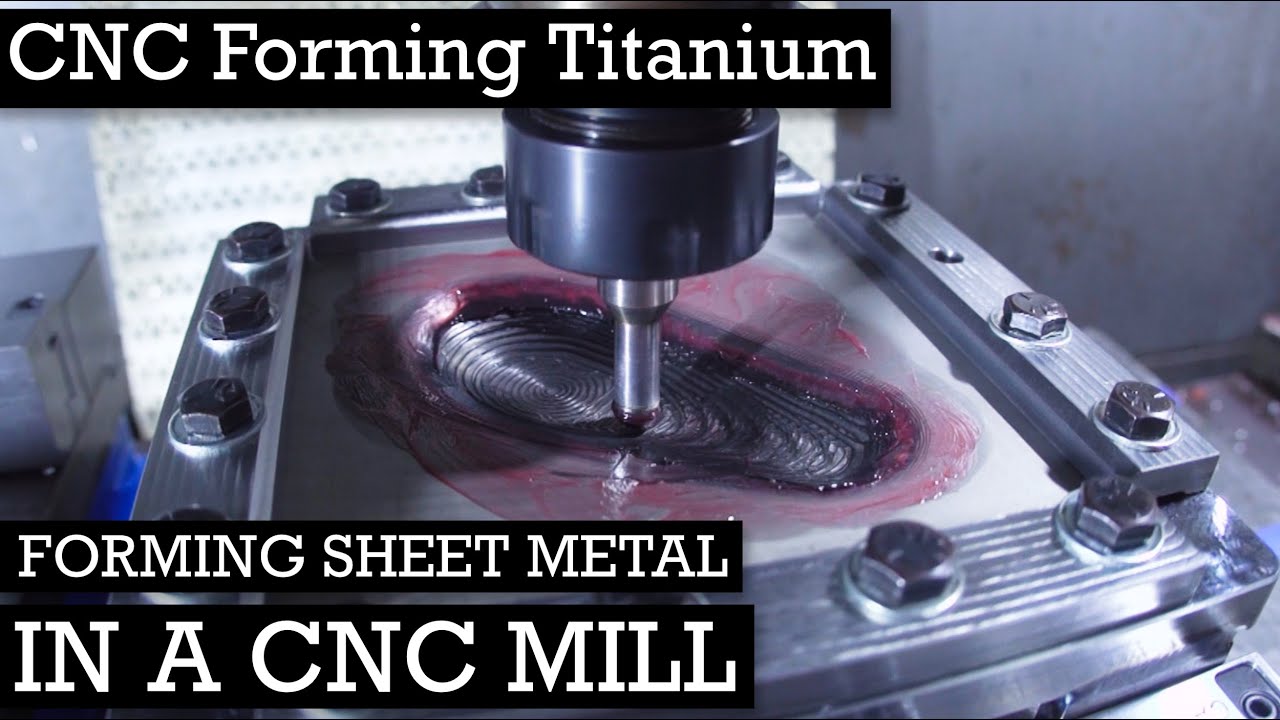

And… while I have your attention - I almost started a new thread called “Cool!” which is a bit different to “Neat!” but here’s Chris Borge again - I like his stuff because he’s young, clever and not trying to “influence” anyone.

His description of this is- “Man turns garbage into more complicated garbage.”

Watch most of the way through for the CNC content!

Love his channel, this guy is “the new Clickspring” ![]()

Interestingly, he did a follow-up comment on this one

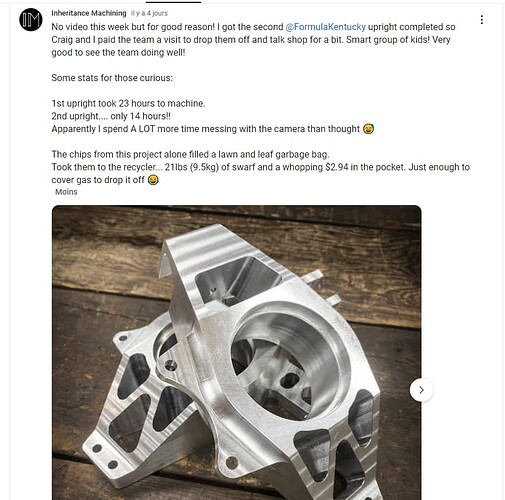

I’ve been enjoying the Inheritance Machining videos.

that may need to be my Signature!

This old Tony tried to do similar metal forming on his lathe to make some metal bowls. It was manual and he had limited success.

OK, I think I found my epitaph…

Welding is a lot of fun !!

get a tig welder and just start going, they are reasonable to get into these days. And have great features for learning on the inverter machines. Or just ask a buddy to try theirs.

Arc and mig welding are the ugly messy welding imo. Tig you can pretty much do in a lab coat.

What I wish I could do is use my welder power supply to power a EDM machine for my mpcnc.

I went MIG. Almost everything I do is steel. Now that I have the basics (sort of), I’d like to get a TIG machine and try aluminum. I also still want a plasma cutter.

I have a decent Mig welder and add on spool gun for Aluminum. Also have a cheap plasma cutter that does great. I would love to get a Tig welder. I have used a few and can do pretty nice looking welds on steel. Aluminum is a whole different animal lol. I have yet to lay a decent aluminum bead with a Tig. If its just a flat plate I can run that no problem. Try to glue 2 pieces together and that’s where I struggle big time. Just need more practice, lots more LOL. Mig welders are so easy and you can get real nice looking welds with them, but not like you can with Tig and a lot of practice lol.