I’ve milled brass on a relatively large Primo with great success. The feeds and speed were very careful of course. I guess if you’re doing lot’s of metal work, a similar kind of machine might be something - but for a metal job once in a while the Primo is great.

Hey @jamiek, nice work on your web based gridfinity tool. Just saw Zack’s shout out…

Cool!

The Milo is on my “want to build” list.

this is a tidy project, but I lobbed it here because it really does show how simple a vacuum former can be.

Oh oh! It looks as though I’m taking over this thread - sorry!

One of my many distractions in life is a community arts partnership that a couple of French mates and I are working on in partnership with the largest technical training school in Australia. (20,000 graduates per year).

I’ll give the project a thread of its own about a year from now when construction starts, and we are actually playing in their foundry and with their machines, but for now…

There are monster machine shops filled with bazillion dollars worth of gear, but the “Neatest” things on campus are the classroom VR gadgets - rows of Haas control simulators (why did I immediately think there’s a project in there for you @jamiek and @azab2c - all the V1e projects simulated on an iPad?)

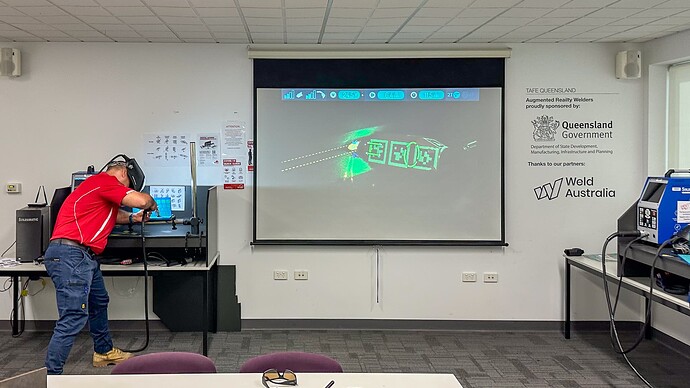

Better still was the VR welding simulator. My mate Dume can weld more than a bit, and he was completely blown away by the reality of the experience. So much so that on his next visit to Aus he’s arranging a few hours of after hours simulator time to hone his skills with different materials and techniques!

I bet there are a ton of people that would pay good money for that!

That would be perfect for me. I really want to learn how to weld, but I don’t like the metal working mess. This is ideal!

There’s a joke that software engineers all want to buy a farm raising goats and retire. But I think we all secretly want to play with the welding simulator.

I wonder if my local school has one.

One of my computer vision projects was measuring the width of a weld pool in an IR camera attached to a welding 6dof robot. But never the opposite problem (simulation is sort of the opposite of computer vision).

Yes it is, more fun than an RC car I reckon. This thing is stupidly real to use too. More info:_ Welding Simulator | SOLDAMATIC | Seabery

If you choose baggy flannel shirts in the character select screen will you catch fire?

I went to welding night classes and we used a welding simulator- the screen was built into a fake welding mask. It was from one of the welding manufacturers, the red one. I want to say Lincoln? Pretty cool.

For any random fitting you need to make, this OpenSCAD parametric file is really cool. I do not use openscad, but I was able to install it and spit out a simple fitting in <30min. Good for dust collection fittings.

Options:

- Connector: Hose adapter

- Connector: Magnet hose connector

- Connector: DysonV6

- Connector: Flange

- Connector: Nozzle

- Transition: Straight tapered

- Transition: Angled

- Transition: 1 to many

https://www.printables.com/model/282014-parametric-vacuum-hose-connector-with-magnetic-con

Here are some of the fittings I printed. Everything seen was designed with the openscad file. I don’t have a good picture of it, but my favorite is at the bottom it is a 90deg elbow that goes from circular to rectangular x-section and includes an option to put a flat spot at a 45deg so it does not need supports to print.

I’ve only caught myself on fire once while welding. ![]()

so seeing the double nozzle, (and i have seen it alot and never thought of this before), I wonder what would happen if one nozzle lightly blew air to the suction nozzle, so there would be a circulation affect.

just a wild thought, maybe this summer I can try it.

as a software engineer i bought 20 acres last year, then chickens and a welder lol

what if the 2 nozzles were offset so they encouraged the cyclone already in process from the cutter?