- www.Duet3d.com Closed loop Nema 23 or 34, with or without brake (auto enables when de-energized). Easy serial daisy chain wiring up.

- Data collection (API and/or service?) enabling anomaly/tolerance/drift detection of individual devices, or across a fleet (outlier/maintenance detection…).

- CANBus module for E3D Roto, includes acc sensor, misc connectors, and bed Z probe capable of 420 points < 10sec yo!

Well, I have a decent starting point (from 2019)

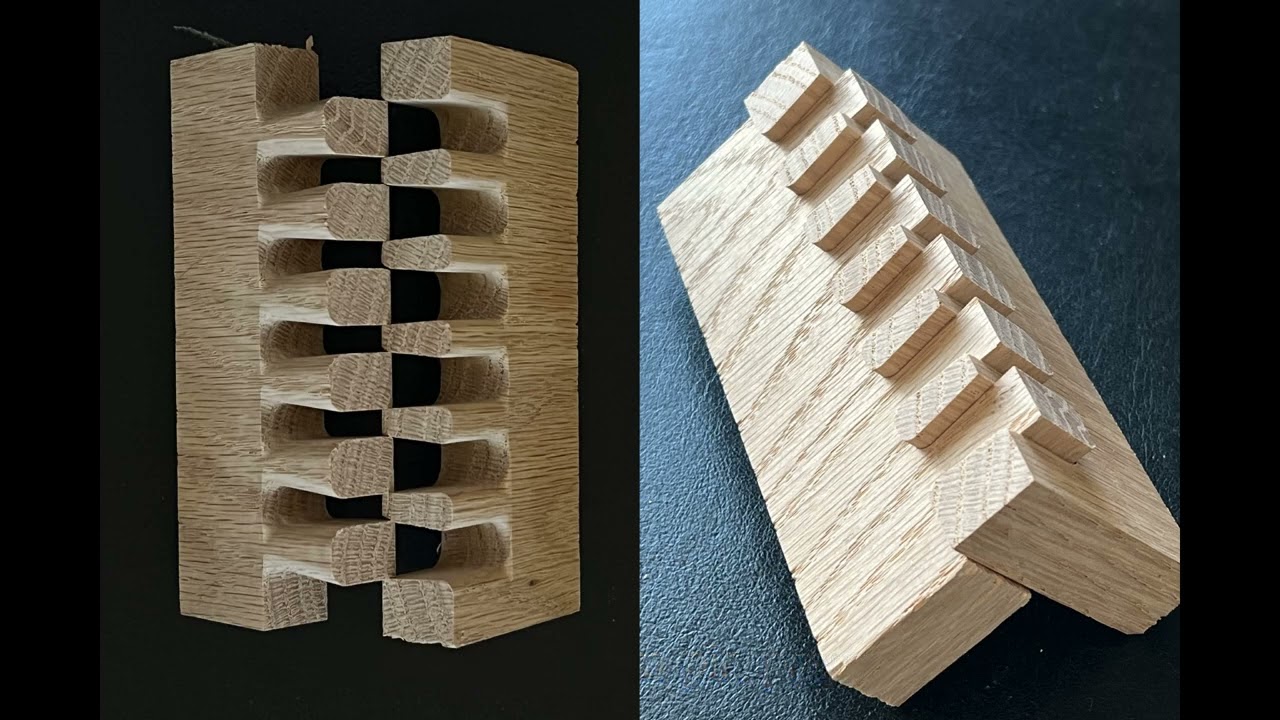

Separately, I have thought about what might be possible with undercuts using a ball-end mill that’s larger than the shank, but I haven’t had any compelling ideas. And I never thought about combining the two ideas for dovetail joints.

A half-cylinder top surface of the fingers and a vertical cylindrical space between the fingers is simple enough. The tricky part is the compound curve on the top surface of the fingers near the root. In my video I cheated and cut away extra material, but I think I have a solution for that surface which I tested in foam.

He just replied on YouTube that he is working on it now and it might take a month or two (if at all).

Yes, not at this size though unless you don’t bother roughing the outside and just sand it later. Just do the cavity and locating pins. I would say a 1/4" ball end might work well for a longer depth like that. The finishing pass will need to be a very small stopover. Interested to see how it goes. I guess I should take a look at that vid.

Yeah, I can get the rough shape with other tools I think.

I’ll add it to the list. Probably will be a while before I try though

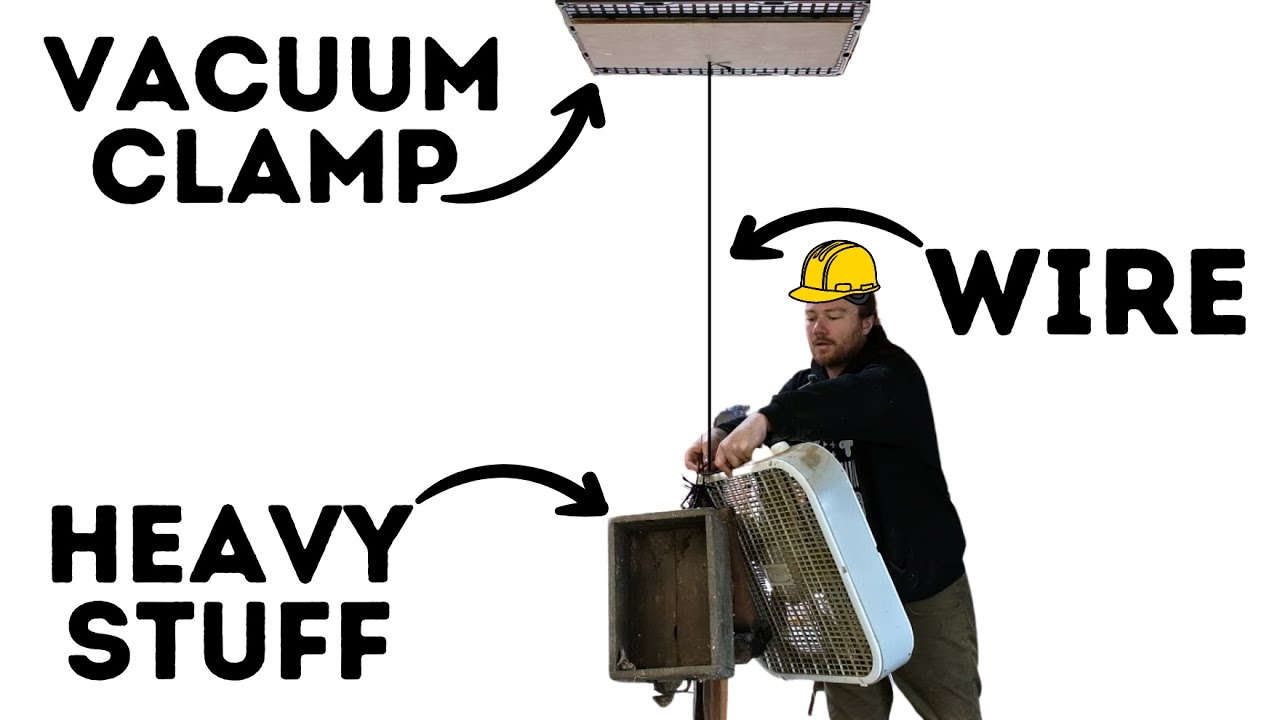

Pretty neat, also a commercial… but he created a 3D printed screw counter as well @vicious1. ![]()

Yea, we have a thread about that around here somewhere.

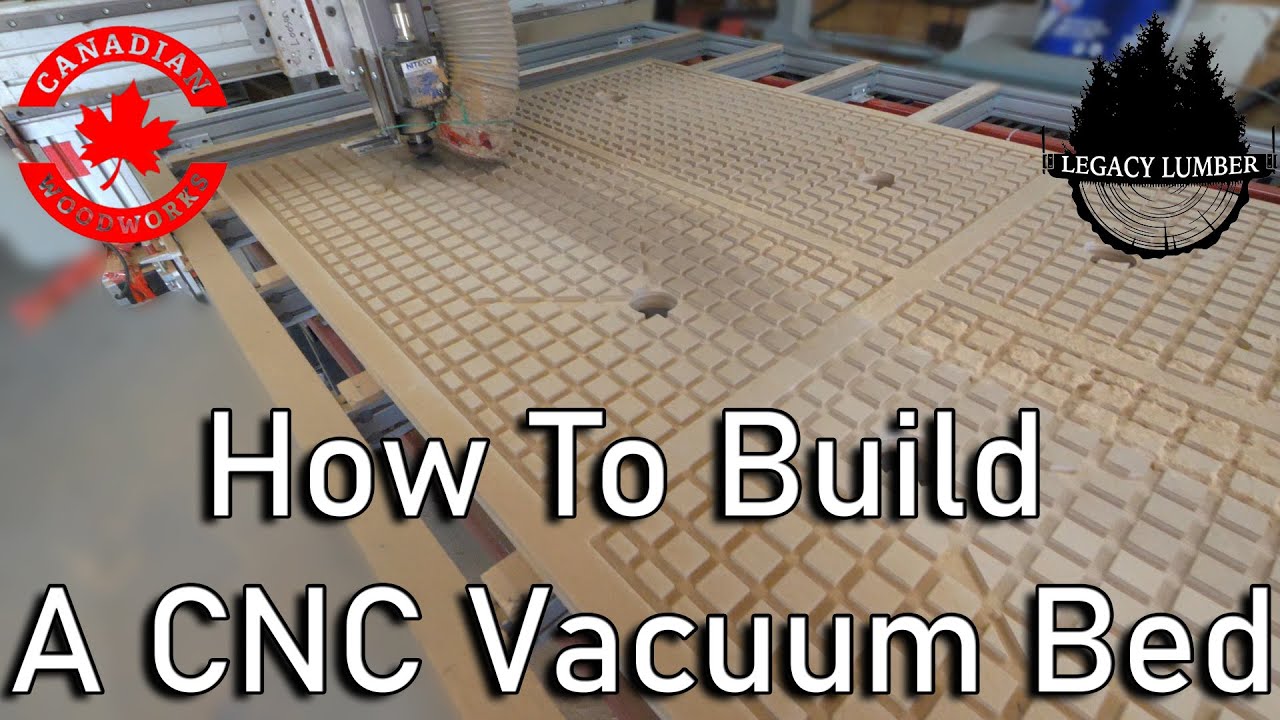

Ok now i had Nooooo idea that a vacuum table sucks THROUGH mdf!!! I always thought it was the channel that held the wood down!! I feel so simple now!!

Yea, you need a good vac for the through the mdf function.

Ha yeah I immediately watched that video too after the one I posted to see if I could make one.

Maybe Ryan will make us a mostly printed vacuum hold down

Did you never have a look at my vacuum table build? Shame!!! ![]()

This was the first try with the Primo:

The new one works with a sidechannel blower and is pretty great as long as the MDF is flat and does not have too many groves. Those kill all the suction quickly. ![]() Also, it does only work for sheets, small parts are not held as well as in his video. I don‘t know how he can achieve this insane suction for small pieces.

Also, it does only work for sheets, small parts are not held as well as in his video. I don‘t know how he can achieve this insane suction for small pieces.

Sounds like vacuum table envy ![]()

A bit, yeah. Though mine is sucking air through 17.5mm MDF. ![]() And cost 250 Euro instead of like 800.

And cost 250 Euro instead of like 800. ![]()

We have a couple CNCs at work that have vacuum tables and we use these vacuum cards to prevent cutting into the table. I wonder if there is a hobby equivalent of this that you could use?

Wow, those are expensive. ![]()