Storytime

TL; DR: I have way more wood than I need. A lot more. And it’s my fault for not checking beforehand

Long version:

So, a while ago I had to relocate my company deep into Odenwald into an old industry plant (I mainly need storage space and cheap rent  ). In this huge plant reside alot of different businesses from small to very big, since the original industry failed and left very nice buildings behind. I personally operate a coffee business and have over the years amassed a stockpile of Espresso machines.

). In this huge plant reside alot of different businesses from small to very big, since the original industry failed and left very nice buildings behind. I personally operate a coffee business and have over the years amassed a stockpile of Espresso machines.

When I moved into my new rooms I needed some lumber to construct shelves and so on - and I walked over to a neighbour that is a wood trading business to purchase what I need. While making arrangements and waiting for his guys to get all my wood from storage he complained to me that his coffee machine is broken and that he is really grumpy because of it and also he can’t offer one to me. We got into a nice talk about what I do for a business and I offered to bring a professional-grade espresso machine and a grinder since I have so many and he could keep it until the repair guy shows up.

But his original machine was broken beyond repair and I insisted he kept my machine, I didn’t need it at he time. In return he marked me down in his CRM that I’m good for a huge favor should I ever need lumber again to settle the deal and he would use my machine until I recall it from him - which was fine for me. Years (more than 6) went by and he regularly bought beans from me, even invested in a Barista education with me for two of his favourite employees and they are really happy with the machine. I kinda never took advantage of that deal.

Fast forward to mid of December 2023. I had just decided to build a LowRider and downloaded the parametric files from @DougJoseph website and just went with the pre-configured one with a 3.625 torsion box. I was in a hurry (Christmas just before the door) and as the instructions said:

Perfect! I need 5 sheets of wood! Time to call the guy!! QUICK! No time to think (which I should have done)!!!

And so I called: “Hey, is that favour still open? I need 5 sheets of MDF, 4 of them 12 and 1 of them 19mm.”

He was like: “Yeah sure, anything else? I have another sheet of 16mm that has some scratched corner, if you want I send this as well, just to make sure we are even with the machine and all…”

“Yeah, we’re good. Thanks.”

No payment required.

Yeah. And then the truck came with a crane and a huge… “surprise”!

Turns out: The MDF sheets in Germany do not measure 2,50x1,25 meters (which would be the rounded euqivalent to 97"x49"). They come in 2,80 x 2,07 meters (110"x81,5").

Look at it. Luckily no one needs to leave that left garage for some days.

Imagine my face when the truck arrived, lol. I spend the whole afternoon yesterday trying to even figure out how to possibly transport a single sheet down our driveway (~10% slope), finally two neighbours offered their help and we carried the sheets down a small runway and in front of my shop. The wind added to the challenge, the weight of the 19mm sheet is insane. It can not be handled by me alone. I’m still having a hard time to even cut them to size

Yeah. And my back hurts really bad today. So I did nothing

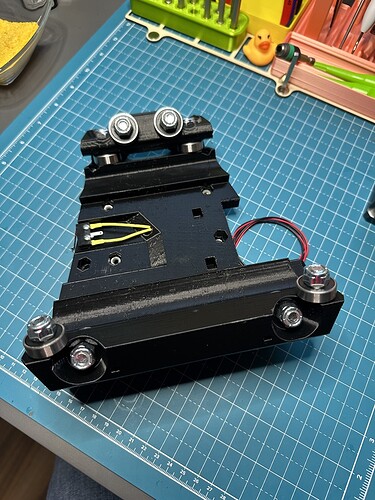

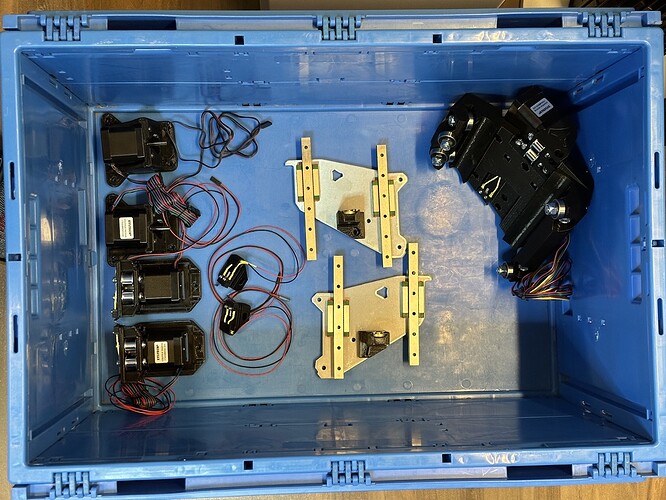

I will continue electronics assembly tonight when the kids are asleep and in the meantime apply some more warmth to my lower back.

But maaaaan, do I have a lot of MDF now for getting to know my machine soon <3

Thank you Doug for the great file for the table by the way!!!

I used the Dogbone Add-In for Fusion 360 before exporting all parts to my Shaper Origin, to have an easier time during assembly of the torsion box since there is no further processing with EstlCAM when using Origin…

![]() ).

).![]()

![]()