I am excited to report that my Portable Primo is working well and produced its first sawdust. In fact, this project filled up my shop vac! It passed its drawing tests after minor adjustments (see my other recent post). Time to do some carving! First I verified that it is indeed portable by rolling it down the stairs from my home Invention Studio and into the car. Then I drove the short trip to the garage and unloaded it and lifted it up onto my workbench, all by myself. (It weighs about 28kg with spindle). The electronics are pretty much all finished and decently organised in a toolbox:

I will do a separate post about the box soon.

I had an old acacia cutting board that was badly worn. I saved it from being tossed, knowing it could be a nice CNC project some day.

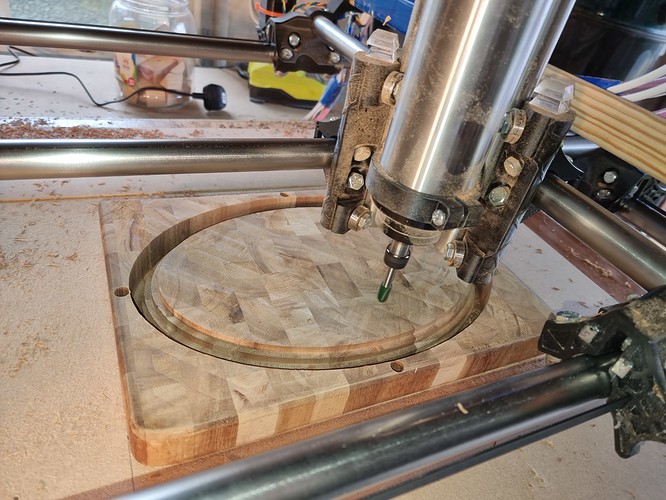

I designed an oval dinner plate in VcarvePro using the Moulding toolpath. This was much easier than making a 3D model. You merely have to draw a profile of a shape to be “extruded” along a path, in my case, an elipse. The nice thing about this toolpath in VcarvePro is that it cuts it by following the guide shape with each pass, rather than rastering or spiralling. So if the guide path is a circle or elipse, all the cuts are concentric.

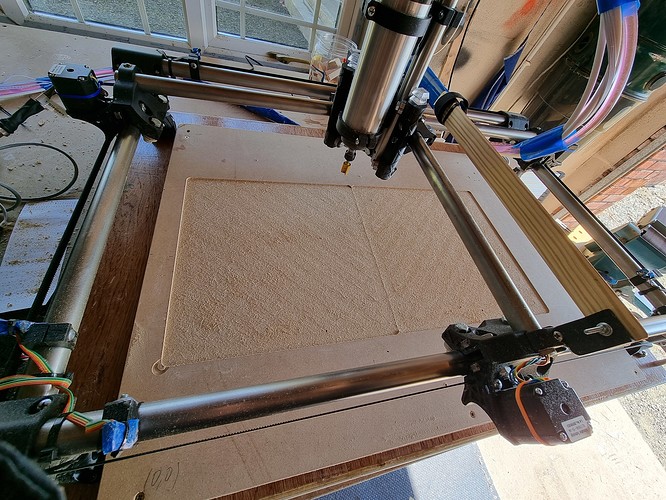

This was a 2-sided job and I knew that flatness of the bed was going to be important, so I faced an MDF spoilboard sheet I had screwed to the torsion box. This revealed that I needed to do some tramming adjustments. I added 2mm washers to the lower spindle mount and it was then producing a very flat surface without ridges.

To check the tramming, I faced at two different 45-degree angles, since the spindle is mounted 45 degrees to both X and Y. Here are the ridges due to a non-perpendicular spindle:

I used the MPCNC to drill precise peg holes for mounting the two-sided job so it could be flipped and stay registered. I faced both sides of the cutting board, which were in poor shape from years of chopping veggies.

On to the carving!

I should have created my own roughing passes instead of using the “Use separate tool for large area clearing” option on the Moulding toolpath, because that option created a roughing pass that was VERY AGRESSIVE (which I failed to notice before I started cutting). At one point, with howling and showers of shavings, the 1.5kW spindle flew through the wood at 30mm/sec with about a 2cm depth of cut! Amazingly, nothing broke and the cut came out perfectly. It is a compliment to the MPCNC design, to my 1/4" carbide spiral upcut bit, and to the powerful motor, which did not break a sweat at 24,000 rpm. Acacia is pretty soft hardwood. I wonder if I would have been so lucky if I were carving oak or maple?

The center of the plate I carved with the 1/4" flat upcut bit. Manually setting the Z-zero for both cutters worked well: there is no lip between the center flat area and bordering curved area.

I used a 10mm round (fluting router bit) for all the curved finishing passes, with about 2mm of stepover at 20mm/sec. VcarvePro’s Moulding toolpath actually varies the stepover depending on the steepness of the cut. It came out perfectly after only about 30 minutes of hand sanding, and a few coats of finish with water-based polyurethane:

I look forward to many more fun carving projects!