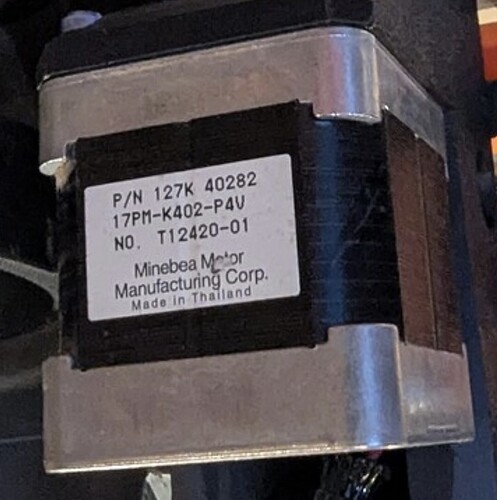

I don’t understand all of this but it sounds like they might be some weird steppers.

Yeah, these are weird steppers. I’m expecting something in the 1.6 to 2.0 ohms per coil range for the resistance.

This appears to be a stepper type issue and not a Jackpot/Electronics issue.

Just for the sake of being thorough, I stuck another meter on the Jackpot. 0.55A while holding 5 steppers, 0.76A (18.25W @24V) while all 5 steppers are in motion. We set the hold and motion amps slightly different to reduce unnecessary heat.

Smaller power supplies cost the same price, and size so I figure more is better.

Sorry, but this doesn’t match my logic on how stepper motors work. They are controlled by the driver.

This is how motors receive power. The drivers need to be set to the motors. Not the other way around.

You can believe whatever you want.

If you intend to have a working machine you’re going to need to address the issue with your steppers being incompatible with your electronics.

Again, I thought in my previous post I made this clear. Yes, the motors will move the machine, if you have more than 75w. This is where is said the operation is normal. The motors step accurately and smoothly, each one.

But, it takes more power than anyone can fathom. Which is why everyone is thinking short. No, I’ve checked. The coils are not shorted. No endstops are shorted.

Again, it will run at 60w with 4 steppers. Any of the four. I tried swapping them all around, maybe I missed something when I checked the first, the second, and the third time trying to isolate a short. Nope.

Help me out then. How do motors receive current?

I do believe you, buying new motors will fix the problem.

However, the driver should be adjustable to the resistance of the motors.

Again, don’t just tell me I’m wrong. Give me some logic behind why I’m wrong.

Did you take a look at Jason’s post above, I promise no one is attacking your knowledge, these do seem to be odd steppers. 6 wire but connected oddly.

The bottom line is they work as intended with standard nema17 rep rap style steppers, yours clearly are not. I don’t really have the time to fully dig into why if you already bought new steppers.

The only thing we control is how much current the drivers use, nothing else other than some timings.

I know it seems like we are not paying attention but there are 49 posts here and most of us are helping at least a dozen other people. We do not always go all the way back and read every post every time. Please just have patience while we all try our best to try and help.

At this point this is done in my mind. Everything tested fine and you have bought new steppers. No need to keep going with this.

The issue IS 100% those steppers for whatever reason. IF you would like some of us to keep looking into those steppers someone might otherwise let’s just be done here. I will ship back your stuff today, at no charge either direction.

We are limited by whatever configuration options FluidNC has implemented for the TMC2209 driver.

You might want to re-read your messages and think about whether your tone is appropriate. All of the people giving you advise have built at least a few of Ryan’s machines. They all agree it’s your unusual steppers, even you. You wouldn’t ask for an explanation as to why a diesel engine can’t be driven with the drivers from the Jackpot.

Everyone here is always willing to help, but getting snippy and snide makes people want to help less. ![]()

Dude, I was not trying to be rude. Honestly, tell me how I’m wrong here. No question, an electronic stepper driver cannot drive a diesel. Please, check your tone. That’s not what I’m asking.

This is also, not my first machine I’ve built from Ryan, but you assume since this is the first question I’m posting to the forum, that I’m new here. I built this machine in 2016, with the motors that are now on the lowrider. I rebuilt that machine three different times.

You were.

I am not going to comment on this one.

One would not have guessed, as unstructured as your feedback and input was. ![]()

Okay, this one is done. We all know it is extremely frustrating when things do not work as we expect. I always expect some short replies, no worries from me. I will close this out. Leighdaweg, I am sending it back if there are any more issues let me know,

Ill take a crack at trying to engineer-splain this electrical issue.

Id be super frustrated by this. And tone doesn’t always follow. So if you could, imagine me as a kind elderly gentleman speaking in a soft measured tone.

It is a wattage problem. Most stepper motor coils we deal with are 2 ohm so to get a single amp flowing, you need like 2 volts. The use of 24v and associated ramp rates and things allowed by that are out of scope here and i dont fully understand them anyway… but back to my point. Power is proportional to iv (current times voltage) or i(r)squared. If r is 13 instead of 2, then the voltage needed to get an amp is 13v and the power needed just increased by at least 6x, so your power supply could very well be under sized and browning out because it was intended for five motors each with a pair of 2 ohm coils… Not 13 ohms. With that much power being dissipated, no wonder they get hot.

That seems logical to me. I hope that helps with understanding. From a credential side, I aced introduction to EE about 25 years ago, so my view is likely limited.

I’ll do you one better…

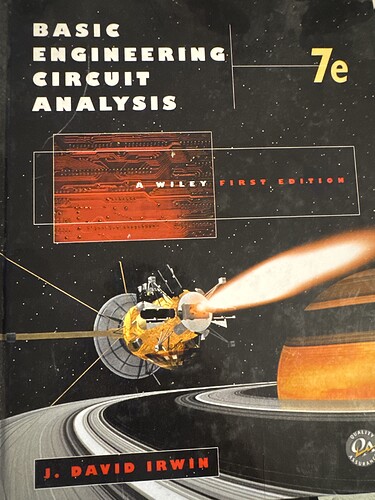

I didn’t ace it… but my textbook is still sitting right here… ![]()

7th edition. Copyright 2002…

Young’ns. I was studying EE in 1990. I’m older than dirt. ![]()

OK, here’s a place where I need to be a bit more humble. I believe you that you’re just trying to understand.

I interpreted your initial dialog as asserting an alternative theory of how things work.

My humble apologies, I’m pretty stressed from combating folks these days who want to substitute some crazy alternative theory of whatever in place of objective realities.

You got a workable explanation above about the EE, I’ll just note that drivers are designed for specific applications and you can’t just assume a driver designed for simple ~2 ohm individual coils will magically work fine when instead paired up with a ~13 ohm series wound stepper. They won’t.

Especially when TMC2209s have a bunch of advanced features beyond the simple drivers that older controllers used.

I can see that you have good building and operations skills for your machines, worth an acknowledgement from me.

Many of us here are just fellow community members, and we do this to try and help our fellow builders along.

I hope your LR works great for you with the new steppers and upgraded controller.

@orob Thank you for taking the time to give me this great explanation. Also, thank you for understanding. Amazing!

Heck yeah, man, me too. Seriously, thank you thank you for the kind words.

@vicious1 Thanks for taking your time to look at everything, and helping me out. I appreciate you sending it back.

Cheers to that! Thanks everyone!

That text book is newer than mine. Ill photo it next week when im back in the office. I think i had the class in 99. Teacher was one of those who separated performance with a clock, so if you could test fast then you did fine. I learned ohms law, kirchoffs law and norton and thevinen’s theories to crank through his tests as a matter of survival. The one thing he deviated on for our benefit was teaching us how to use op amps in circuit design, which isnt typical for a 101 intro class. It was cool. If i could go back in time, I’d do EE more.