I’m a bit rusty but an online calculator suggests about the same moment of inertia for a 25mm, 2mm thick tube as for a 25x25mm 2mm thick L-section measured half-way up the centreline of the vertical web…

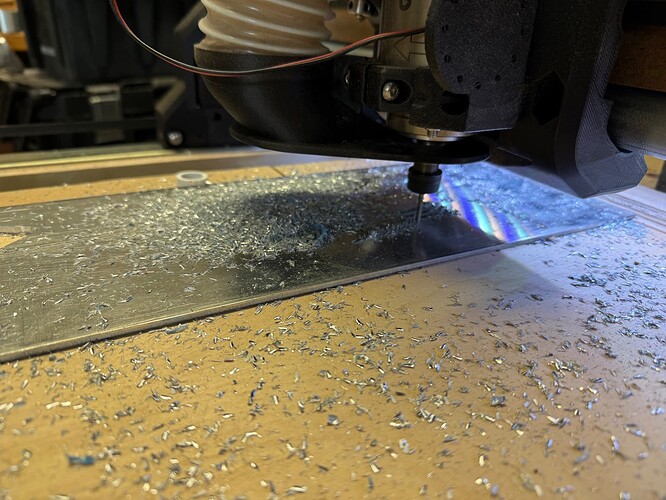

In the LR1 days, the MPCNC was better at metals. At some point, that changed. But it is always hard to compare when the LRv4 builds can often cut 4’ wide sheets.

Bump…

We all had lots of ideas at RMRRF, I do plan on another version but I am not touching it until I complete the LR4 docs further.

Been a while since I read through this thread, so getting caught up. I aplologize if this was said where I didn’t see it.

Or help folks new to the CNC world help decide which fits their needs best.

A little late to this but as a hobbyist the biggest pain point for me is that running a job is a messy, noisy affair. I have a 4’x6’ LR2 and a 13"x30" Primo in the shop.

With the shop vac running I get 90% of the dust but there is still a thin layer on everything and I still have to wear breathing and hearing protection and have to take a shower after the job is done.

Something that was built around good dust collection/enclosure and maybe utilizing a quieter spindle would be welcomed. MPCNC seems like a better candidate for that than the lowrider.

Perhaps a stock size cover (say 2’x4’) could be designed and sold to fit onto a 2x4 piece of ply base and a standard build be documented to fit it. Bonus points for laser compatible materials. Add holes to enclosure for fans, vacs, etc.

Just my $.02

I’ve read most of this thread and I’d come at it from a different direction.

The MPCNC as it is, is a great entry level machine. With the prerequisites that you’ve got some basic tools and preferably a 3D printer (or access to one) to get you going. So, in iterating the design you can’t go beyond these prerequisites and of course if it gets too fancy looks too hard then people are put off. Therefore, either the next gen should be more performance for the same level of complexity or a reduction in complexity (total part count).

What’s more interesting to me is something else. The entire history of the industrial age is built upon people using the machines that they have to make better machines. Going back to the MPCNC prerequisites for the next machine add access to a MPCNC and the skills to operate it.

Now what type of machine can you make then? Rather than mostly 3D printed, it could be a mostly machined out of Aluminium plate for example, and if so, what capabilities do you get as a result?

I guess it becomes a market demographic question… Is the target:

- the absolute newbie: 3d print, basic assembly and yellow brick road?

Or

- the pro hobbyist that wants the next level of milled diy machine without the next decimal place in the cost column?

Edit: maybe it could be the first with a well documented path to the second via bootstrap. Bring in the newbie and in the process of teaching and them learning how to cnc, they upgrade capability to build itself better into the pro version. Sounds nice.

I think the MPCNC is the gateway drug to CNC and should, in the basic version, stay simple, 3D printed and affordable.

I think the MPCNC needs to be the gateway. For sure. Can it be made 1- easier to build and use, 2-less expensive, etc. Secondary would be smaller footprint to workspace ratio.

I think both of those things are pretty hard to do better. The MPCNC is really simple to build and really affordable already.

I wouldn’t worry about the less expensive part too much. You already hit an attractive price/performance balance with the product and any savings you probably wouldn’t move the needle for most builders.

I’d say the parts that could be better on the Primo would be the tramming/squaring procedure ,wire management, and dust collection.

The main reason I break out my Primo over my LR2 is because I have it set up to be portable (with a handle) so I can carry it outside, toss it on some sawhorses and not have to worry about the dust/noise issues but I think I would prefer a smaller LR4 over the Primo if I was doing it over again.

I found i was annoyed with the mpcnc core movement system always in my way. Too many pipes and always a bearing working loose. Some of that may have been build quality, I’ll admit (and the excessive use i put it through), but the lowrider 4 is much easier to work around loading and unloading, sharing the table with other projects… Guess the entry level part of that worked for me.

The other idea that was floated at RMRRF was just bringing the cost of the LR down and getting rid of specialized parts (XZ plates, maybe even the strut plates), foot print reduction. If we only focus on one machine everything is easier, and economies of scale come in faster.

I do have an idea…it came to me last night while watching a real engineering episode. Nothing directly correlated to the episode itself, but I guess my brain kicked into full geek mode and I got a good idea. I spent a while sketching things out this morning, I will get into CAD when it all makes sense.

So maybe the LR5 is the next mpcnc. Honestly, the only thing the LR is missing from all your requests I think is tramming. Most of you hate shims (I actually don’t mind them at all), they are the path of least resistance.

I’d also like to have the “pro” option on the LowRider to modify the tool mount section of the core so you can fit adapter plates on it, so one could fit a different mount like this easily.

Why?

The mounts we currently have are superior to that. That looks to have at least a 15mm stand off, we only have 2.5mm. we are 6x more rigid already.

The mount as is, is very very easy to adapt to anything. 4 flat screw holes.

It’s just a me-specific use case, my spindle needs to be that far away, it’s only got 43mm circumference at the bottom.

A flat plate universal mount only makes sense on a metal machine.

Whatever the tool is my CAD files should be easy to edit to make it work. I guarantee you do not need all that metal for a tool that will not see more than ~9lbs force.

At this point, lr5 would need to offer me a whole lot more. I am very very happy with my lr4