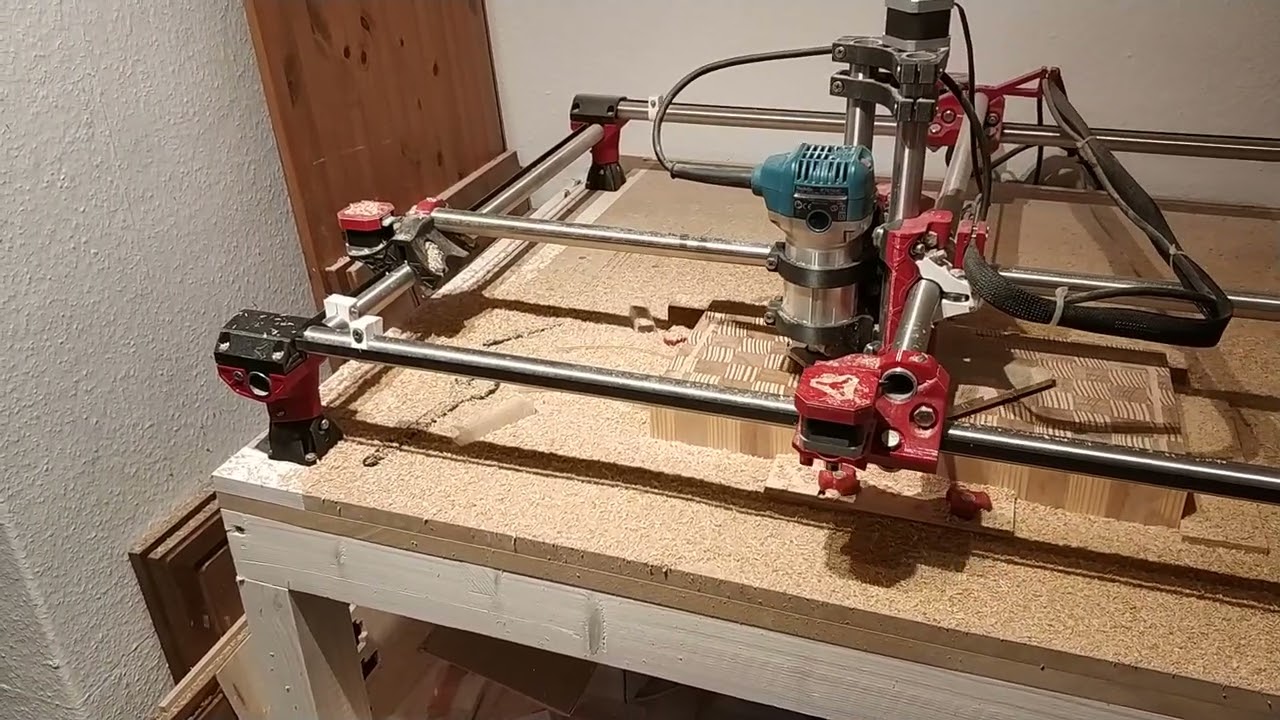

I also made a video for you planing end-grain oak at 2000mm/min and 5mm DOC with my 16mm endmill and a relatively low speed of 3 on the Makita, whatever RPM that might be… The chips are flying and the MPCNC did not even stutter once.

Impressive! And live-action or video, I doubt it ever gets old watching a CNC machine at work.

Ohhhhhh, I have a ton of pallets at work for those cleats!!!

Got me some wood. Ash and Maple. The Ash looks so stunning when planed.

Maple:

Ash:

A lot of it… Two boards:

Planing the maple:

Clamped together. Look how beautiful that Ash is. I am blown away by it:

It’s going to be a cutting board for my brother’s birthday. Hopefully on time.

I now mixed F-Engrave and Estlcam, because I could by the life of me not figure out how to separately cut the keys them with F-Engrave and set the 0 freely. So I made the cutout with Estlcam (2 Layers) and cut the keys with F-Engrave. That works pretty well. There are some really, really minor gaps, but I am happy. Will cut the other key in the next days. Hopefully it also fits.

I upgraded Schneewittchen and gave her a drag chain for the Z-Axis. The tape measure trick didn’t work out since it would always get caught on the stepper on the right side. Ugh. Now it is working like a charm, though I couldn’t spend much time with her because of my new baby girl (like, a real girl, not a lowrider or sth… :D).

First “real” video with a simple project my wife wanted me to do. First time with the camera, no boom arm yet. ![]()

Watching it I am thinking I could have shortened it a bit more. ![]()

Hi Philipp,

deine MPCNC ist echt nice und deine Printed Parts sehen Hammer aus. Hattest du beim Zusammenbau irgendwelche Probleme, das etwas nicht passte? Meine Z-Achse macht mir große Schwierigkeiten. Die Kugellager haben nicht gleichzeitig Kontakt und dadruch ist alles etwas wacklig.

Vielleicht hast du ja einen Tipp…ich werkel schon seit etwa 6 Monaten an der MPCNC rum und bekomme einfach kein dreh rein.

Liebe Grüße aus Bremen

Man muss die Schrauben fester anziehen, als man denkt. Der “light touch” der Anleitung bezieht sich eher auf KFZ-Mechaniker.

Hab die gesamte Core-Einheit nochmal auseinander genommen und setze sie nochmal zusammen…ich finde deine Stepper Cover ziemlich cool woher hast du die?

Good luck with that. For the covers see here: Golden Primo First build - #113 by wellthad. You have to program a colour change in between. Also you can’t attach dragchains to the steppers that easily any more.

Oh Forgot English Community.

Last question if i may ask, what Dragchain Mount for Z Axis is that? i’ve been looking for it everywhere cant find it…mine is pretty shitty

No worries. Here is the link to my Frankenstein DragChainMashup: Printables (no screwing around!), the original from which I remixed it is there as well (Printables), also a link to the dragchain (which is pretty awesome!): AR cable chain link opened by arek_r1 - Thingiverse.

This is Z-Axis holder for the chain that does not actually attach to Z. Pretty neat: XYZ Cable Chain for MPCNC Primo by laooola - Thingiverse and this is the “screwblock”: Screwblock by Kaligma - Thingiverse I created to hold the chain.

Hope that helps.

Could you suggest a torque value? (Hast Du einen Vorschlag für das erforderliche Drehmoment?)

Gruß,

U.

Wood glue and toothpicks will take care of the original holes…then you are good to go on the new holes.

Hey Ulli, great to see you again.

But no, regrettably I do not have a value. I just go after how it feels after playing around for quite a while.

Thank you very much. You helped me a lot. I will keep you updated if your tipps helped me getting this machine to work

I build several 3D Printers by my own but so far i’m not able to build a working CNC sometimes i want to

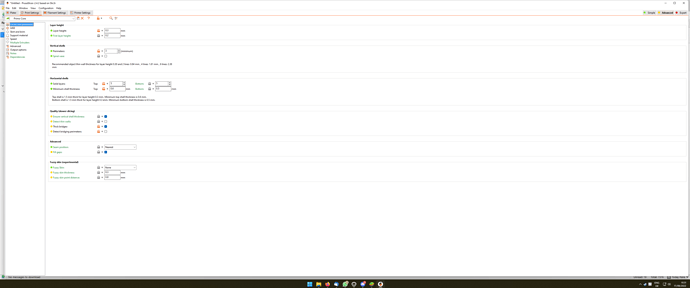

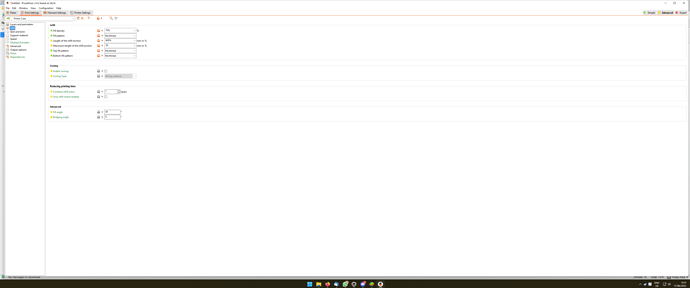

Your printed parts look really good. I have a prusa mini too and I feel mine don’t look as good. Do you mind sharing your print settings?

Sorry for the late reply, was on vacation.

Those are for the core, for the other parts just change infill to 45% (there is variable infill now which might help with the core, but I never did that).