Hi,

I invested some days to figure out how to perfectly square my MPCNC.

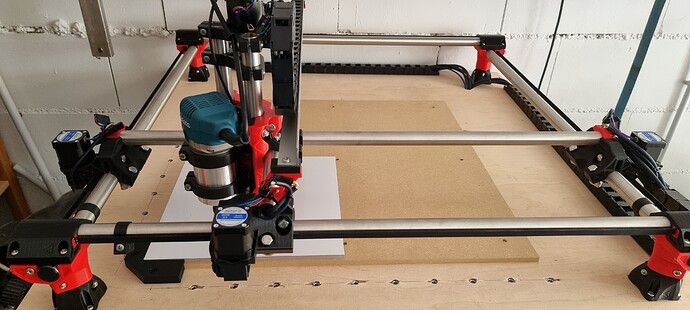

Build size is 610x610x81mm and I managed to get perfectly matching diagonals and sides by drilling 5mm holes in each corner, putting precision dowels pin in and measuring distances and diagonals.

However the distance between those dowel pins is -0,77mm less than it should be (584.23 & 594.23 vs 585.23 & 595). I ignored that and adjusted the diagonals. Perfectly square!

Then I switched from a 3.175mm cutter to a 2mm and suddenly the machine isn’t square anymore. The distance between the dowel pins for X in the back don’t match the one in the front, Y both match. The diagonals are off by 0.5mm which doesn’t sound much but that would result in one side being 2.67mm shorter than the other side when routing 600x600 plates.

I tried adjusting steps to get perfect X and Y distances however as I did that after the switch to the 2mm cutter I don’t know if it worked or not because the diagonals were off.

I have dual endstops, Klipper and use F360. Motors are the Stepperonline 48mm 2A ones which I run @ 1.2A. tmc2209 and powge belts+ pulleys. Stainless steel rails, Makita rt0700 with a 1/8 collet from Elaire. Belt tension is equal for all 4 belts.

Any ideas why that happens? Also from reading through the forums it seems like diagonals off by 0.5mm is acceptable. That would, as said, cause one side to be off by 2.6mm which is worse than I could do by hand.

Edit: I used Loctite on the pulleys