A friend of mine did this on a much smaller build. I think he was using 4 heating pads. If I remember right, he got the temperature out of Octoprint somehow. Not sure if that’d be useful for you or not. One thing he talked about was that the mass of the heating bed made it really easy to control the temperature of as it’s a massively damped control system. He said his logic ended up really being an if else statement. He started off trying to do some type of coasting algorithm, but ended up not needing it.

Bad news: the USB-C cable I’ve got doesn’t have the full set of wires… apparently it won’t be easy to find a cable featuring all the wires in the lenght I need (3 meters). Plus I’m not so sure now that there will actually be as many wires as I thought inside… Can’t find any clear information on how many wires those things actually have.

Wikipedia also mentions some kind of chip inside, which can somehow talk with the devices to give them information about the cable itself… It sucks, I thought it would be easier, that makes things more complicated. the only 3 meter wires that seem to feature “super speed”, which I assume means that they have all the wires in them, are quite expensive (15 bucks), so I’m not really sure I want to buy one just to find out it won’t work…

If it gets too annoying I guess I could also go with micro HDMI, it’s easy to find some nice and long cables too and they also have lots of pins. Only thing is that they are not officially rated for a lot of current, but I guess it’s not really a problem.

Why does the cartridge heater take 8 wires?

But this is making a lot of sense. The whole point is to have it be a commodity cable and if it is too hard to tell WTF is inside, that is a deal breaker. What about more copies of USB cables? At some point, we are approaching the ethernet or db15 solutions.

4 wires for positive, 4 wires for ground, I guess to split the current otherwise the wires and the little contact tabs of the plug might just melt. I based that on the pinout from the plug.

But in the end this doesn’t matter, my USB-C cable only has 5 wires inside it… can’t do anything with that it’s barely any better than a random usb 2.0 cable.

More usb cables is an option, but I’d need like 3-4 of them so that would suck.

Ethernet only has 8 wires, so that would be two of them.

db15 are big and bulky, I’m not a big fan.

Not a big fan of how they look too, most of the time they are made out of cheap and hard PVC.

I need to investigate a bit more, but hdmi actually looks like a good solution, it can be just as small as usb-c, lenght apparently isn’t an issue since they are up to 50 meters, some of them look real nice and they are not that expensive either.

Well this news has surely bunched up my underwear. ![]()

Sorry, didn’t understand what does that mean?

(English isn’t my mother tongue so I don’t always get all the references ;-))

Anyway, the fact that usb-c doesn’t seem to work might end up being something good after all. I found out those hdmi conectors which seem to be perfect for what I wanted to do:

It will be really handy on the carriage side!

Imagine a broken heating element, a defective fan or a bad temp sensor, I wouldn’t have to unsolder anything, just turn a few screws, replace the thing and boom.

Well, hopefully no boom. Just regular, normal sounds would be better.

“Don’t get your panties in a bunch” is an idiom (terribly sexist, I might add) meaning don’t get all worked up about something. Therefore if his underwear is bunched up, he’s annoyed and bothered.

Aaaahhhh ok got it, thanks!

Lol. Sorry. It’s an old saying. I actually had to look it up for clarity.

Google “knickers in a knot” and the more modern version “panties in a bunch” when you have some spare time.

I was trying to express my disappointment of the usb-c cables not panning out as a cheap but nice option for our projects.

I love watching your mind work. Hopefully the hdmi cables with work for you.

Very cool idea. Are you just using this on your center assembly or will you be using HDMI cables/connectors at each stepper? So standard HDMI is 19 conductor + shield, correct? I did a quick search and found the screw terminal breakout you posted at adafruit for about $5 via digikey, and Amazon has 10’ HDMI cables 22awg for about $10. I can see where this could be a pretty compact setup for a lowrider design where y, z, and limits could run in a single cable. But could get pricey.

I’ll only use it for the center assembly, so heating cartridge, fans, BL touch, sensors, LEDs and other stuff I might add later, like a second nozzle.

The USB2.0 is perfect for the steppers and it works fine so I’ll keep using it for every motor.

I think in the end the HDMI will be a better choice than USBC ever was. The wires seem beefier, the terminal pins are stronger and bigger, it should be able to handle more current per wire and per terminal so instead of having to use 8 pins for the heating element I might be able to get away with just 4.

22AWG seems nice, I was only able to find 24AWG. I guess it’ll work too, already bought all the stuff anyways.

USB 3.1 has to have more than 5 wires but if the cable is made to support USB 3.1 speeds it’s going to get expensive. And I’m not sure how many wires exactly it would have either. Maybe length limitations too.

And the other risk is a usb 3.1 cable might have a chip inside. The last thing you want is a resistor between your temperature probe and the heater.

I would still like to think I was capable of making a little pcb with a usb connector and a bunch of attachments in a single usb C. It would be great if there was a simple solution like that.

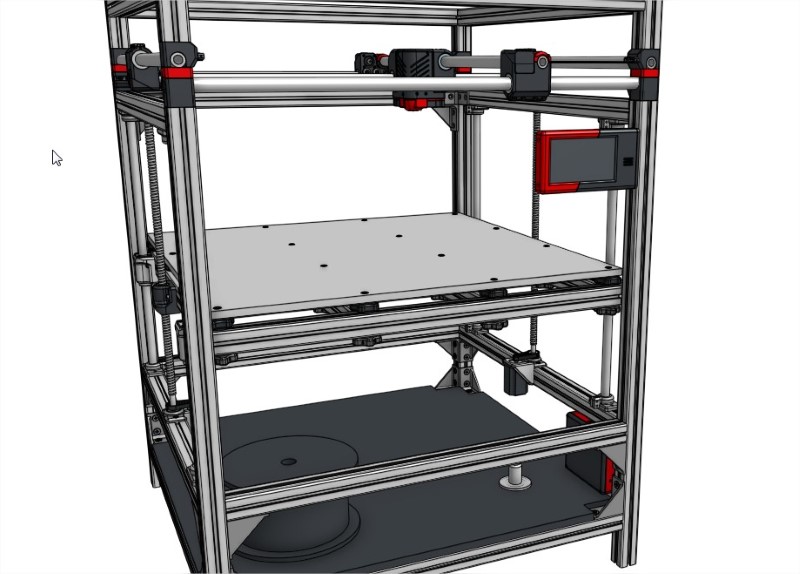

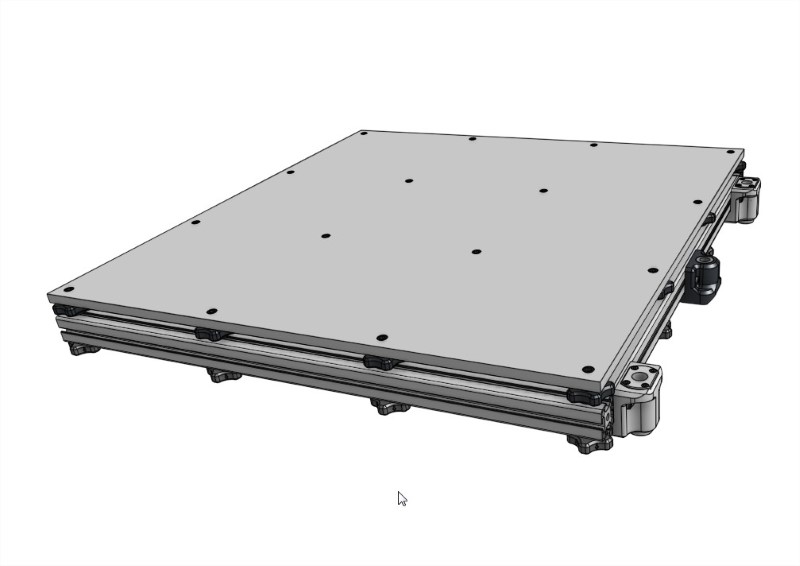

Ok I think I’ve got a design I could live with for my bed now. I just need to check the motors lift power in order to decide if I go with 10 or 15 mm for the aluminum plate, but other than this I’m pretty happy with this design.

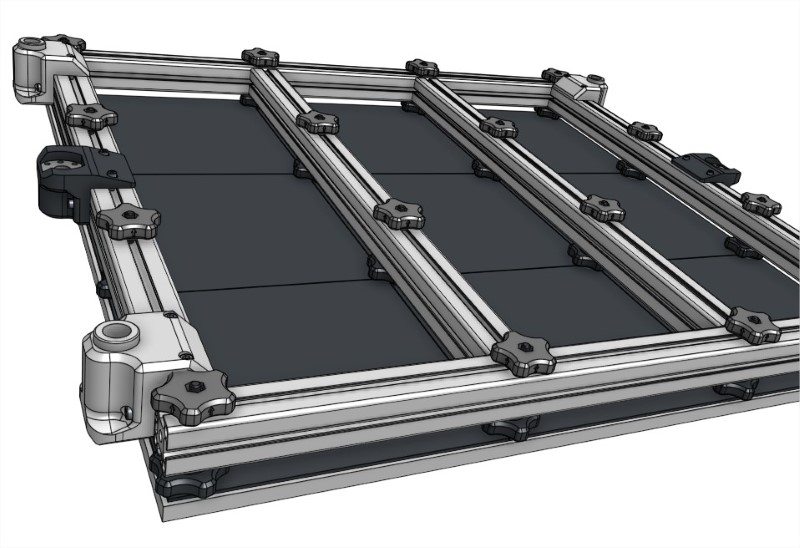

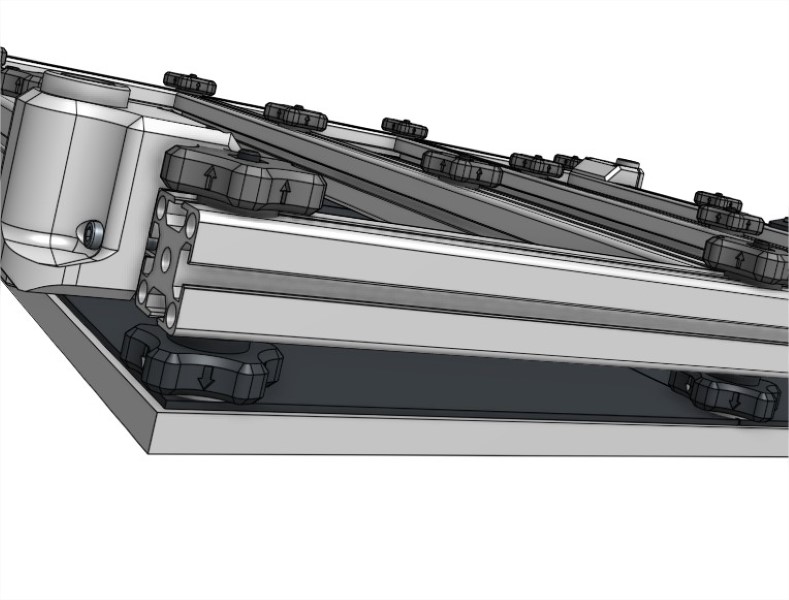

So, the plate will be secured with 16 M8 screws, spaced at regular intervals. Then there will be two adjusting knobs: one for adjusting downwards, and an other one for adjusting upwards.

This way, I can adjust the general tilt of the plate, as well as correct some planeity defects.

Shoud look something like this:

I hope it won’t be too heavy for the motors, the whole bed might weight around 40 kilos, it’s definitely not light.

Your build threads are always pretty fun to follow Dui. The next project I start I will try and remember to post updates more often. I typically just go into tunnel vision until whatever I am building works or fails, then post any pics I took along the way. You have a good eye for sharing the steps you took, good or bad.

Thanks!

Thanks Ryan!

I like to share the design process with you guys because there are always lots of good suggestions, things I haven thought of, or just friendly support which actually really helps pushing the projects I’m doing. Feels like I’m part of a team and we have to get things done XD

Also later, I can come back and see all the mistakes I’ve done, and sometimes also surprize me with the details and things I’ve thought of at the time, it’s like a small time capsule.

I don’t usually comment because this is way out of my wheelhouse, but I’m over here silently cheering you on!

It is inspiring to see your projects I just dream of pulling something you have done off

You’re doing horrible. You should give up and send all the parts to me for safe storage. ![]()

![]()