Hi guys,

A little experiement I made yesterday that could be interesting to share here: electroplating 3D prints!

First time I tried and it worked pretty nicely so I thought it would be interesting to share with yall.

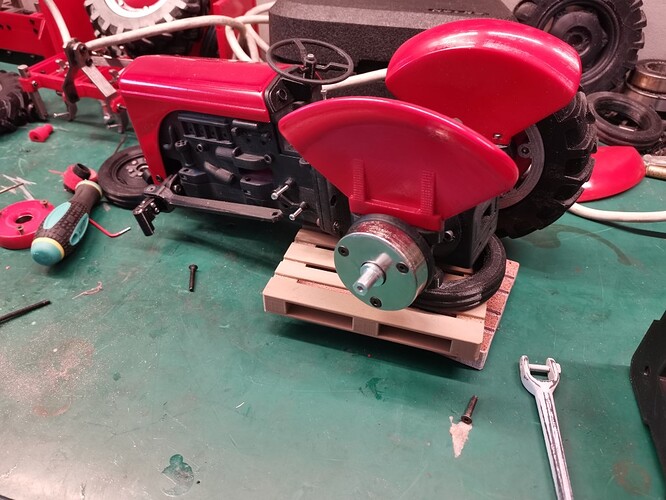

Still working on making the final version of the little tractor for my nephew. Most of the parts are now printed either in ASA or in PETG and now I’m working on getting a cool finish. Almost everything will be painted, but for a few ones I thought it would be interesting to try electroplating.

The advantages are that it is tougher than paint, it slightly helps to strenghten the part, it looks like real metal (that’s because it is real metal!) and more importantly maybe, it feels like real metal when you touch it.

So for that I bought a few ready made plating solutions from a shop specialized in electroplating. I could have bought all the chemicals separately, but it was easier to buy the stuff already made by people who know what they are doing, and the cost was even cheaper. These baths can be reused many times so it worth it if you plate a lot of stuff.

Anyway, I first printed the test part with ASA on the BOx. It is the exhaust pipe of the tractor. I sanded it smooth, then applied some primer. I realized later I did a poor job at sanding it smooth, I would have gotten a much better result if I spent more time on it, lesson learned.

Then, I spray painted some conductive paint on it. This is the base on which the metal will later adhere to.

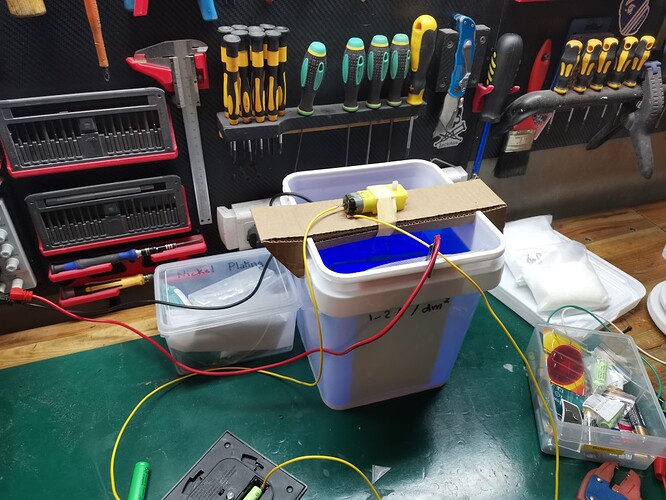

After that, I prepared the copper plating bath:

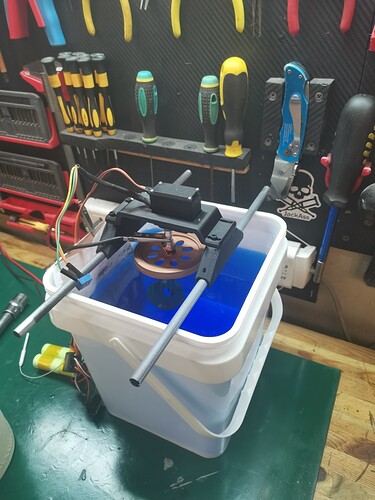

The part is attached to a little motor which turns it slowly, this way it gets plated more uniformly. The cathode is made of pure copper and the anode is the part itself. When a small electric current is applied the cathode dissolves in the bath and its ions then stick on the anode, progressively forming a metal layer. The longer it stays, the thicker it gets, but when it gets too thick it doesn’t stay smooth and uniform so you can’t easily make super thick coatings. You could, but it would take some sanding.

Anyway, it stayed in the bath for 30 minutes or so,

I then took the part off the vat and tadaaa:

The part is a little bit heavier, it feels just like real metal to the touch and there is good continuity when you check different spots with a multimeter (I didn’t get good continuity while doing the same test on the conductive paint, interestingly).

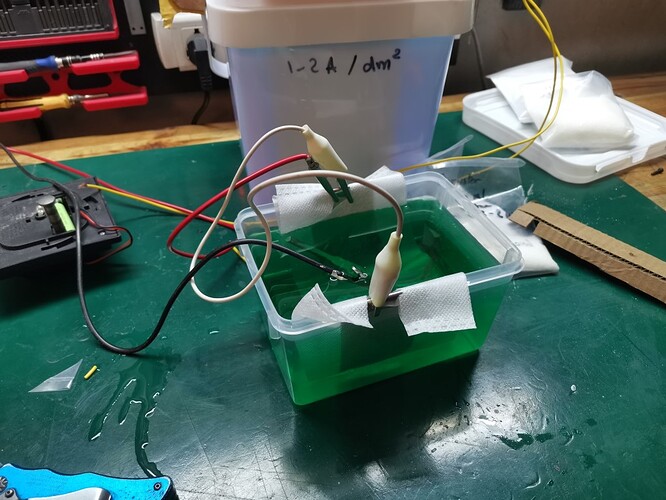

Next I degreased the part and prepared the nickel plating bath:

Nickel plating worked just the same, but I didn’t have a big enough container so this time I couldn’t have the part spinning.

I left the part here for a relatively short time, less than 5 minutes. I suppose I could have left it for longer, I’ll try and see next time.

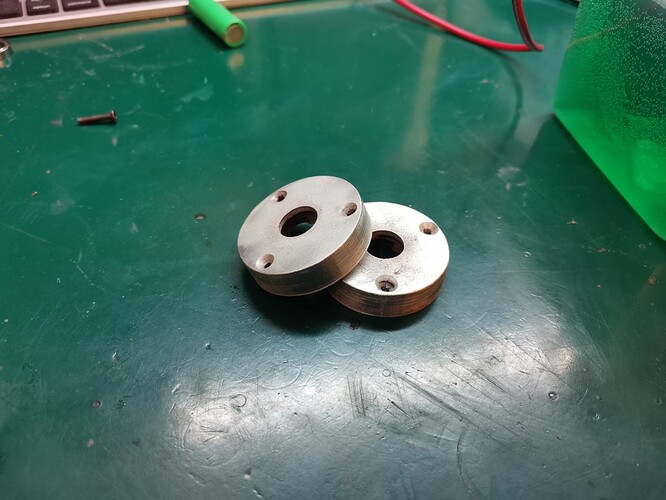

Anyway, I rinsed the part and here is how it looked:

Pretty cool eh?

I really enjoyed this process, it wasn’t difficult at all. I think I’ll use it a lot from now on.

Installed it on the tractor, it’s a small detail that no one will probably notice but I think it’s cool. What I like most is how it really feels like metal to the touch, only the weight tells you that there’s something unusual about it.

I’ll do the same for all the front suspension parts.