Hi guys,

It finally happened, my mostly printed watercooling system failed on me last week!

Interestingly, it didn’t fail because of any of the parts I designed, the root cause of the failure was the death of the water pump. As I had no way to see if there was any actual flow in the pipes, I did not notice it before it was too late. I was printing a small part and suddently a few droplets started coming out of the print head.

Nothing dramatic happened, just a few drops of water here and there on the build plate. It ruined the print tho, but it was a small print so no biggie. Also I believe this was the printer’s way to tell me to clean my build plate… I haven’t cleaned it for an entire year, if was abslutely filthy.

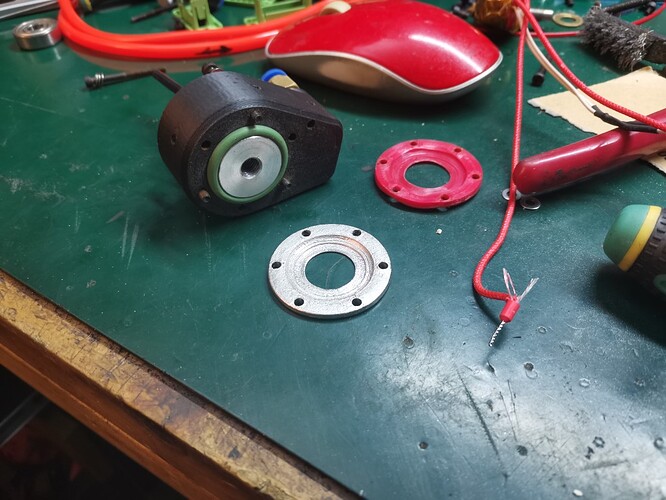

First I took apart the cooling block to check how it was inside:

As you can see, the red cover was severely bent and this is what caused the leak since it didn’t apply a uniform pressure on the seal anymore.

Also, interestingly, it seems like some fins corroded on the aluminum heatsink.

There was a little amount of white build up material inside, but nothing dramatic. I use regular water from the tap to cool the printer, nothing fancy, no anti bacterial stuff. Might be better to use some, but I’m a bit lazy.

Anyway, the cooling block was fine, the seals were fine. Seems like the only part who didn’t stand the prolongated heat exposure was that little red ring. Kinda exepcted because it sits very close to the heating block, i’ts already a small miracle that this part was able to survive for so many years and through so many prints.

I could have just reprinted that and it would have been fine again, but now I added this new electroplating skill to my toolbox so it was the perfect opportunity to use it!

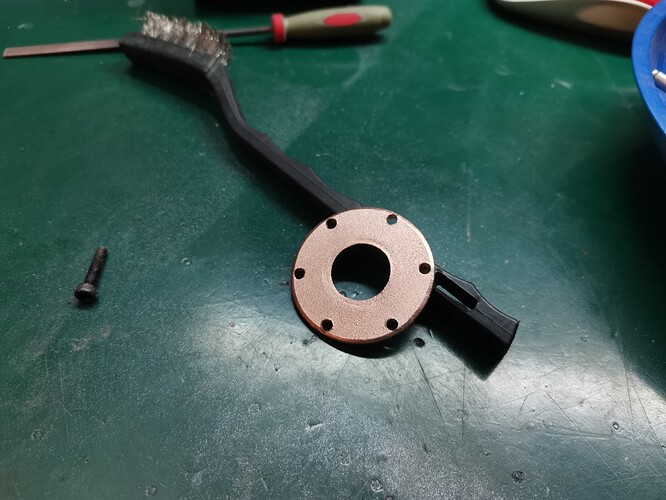

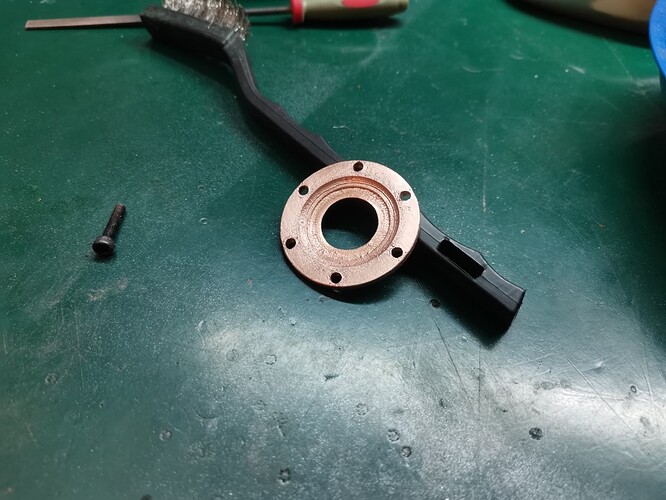

So first, I printed a slightly smaller version of this ring (to account for the metal deposition thickness, which was around 0.6mm). First plated it with a thick layer of copper:

And then a small layer of nickel afterwards, which protects if from corrosion and also makes it a bit harder/tougher:

Then reinstalled this on the cooling block:

And finally the cooling block back into the print head:

Tested for leaks and so far so good. The part is a lot stiffer and stronger than its PLA counterpart. It’s also significantly heavier.

I think it will perform pretty well. Being made of copper it should also act like a small heatsink and help dissipate part of the heat. Meaning an ever colder cold side, pretty cool

Still need to be tested on a print, but I don’t see how this wouldn’t work.

I will also add a little thing to be able to visualize the water flow in order to be quickly aware in case something goes wrong with the pump. But if this happens when I’m not around at least the heat shouldn’t ruin the print head anymore.

I had a scrap part made of PLA plated in the same fashion, I exposed it to my blowtorch for a few minutes: the PLA inside the part melted and vaporized completely, but the metal shell stayed perfectly fine despite becoming red hot. So I know this plating is actually quite tough, it’s not just cosmetic. Even if the plastic melted inside it, the part will keep most of its structural integrity. I might even use this technique to make some complex casting parts on my motorcycle.

I really like this plating thing, it’s very close to having the ability to 3D print metal. It’s a little bit more work of course (lots of sanding to prepare the part and remove imperfections), but most of the work is actually just waiting for the plating to happen.