I might be hyperfocusing on this build, so I’m seriously lacking pictures and documentation, but I noted down some important stuff, I’ve just been so excited now that I finally have everything (I think) to build this stuff.

first, the bench!

I made a surprisingly pretty bench for my CNC (I thought it would look way worse), I wanted to design my own but instead I went with a simpler and more elegant design from Matthias Wandel, the build was very straightforward, for additional info you can follow Matthias video.

my main mistake is that for various reasons, the structure wasn’t as straight and square, nothing too serious, but it made it a pain to add drawers, I didn’t add the drawers in a proper manner, I’ll be more careful next time, but hell it looks pretty, and those drawers will help me SO much for storage and organization.

(my mistake is that I mounted plywood sheets into the bench, so I had to crawl down there to screw the rails and everything, I’m young, but not young enough to do this a second time, If I made a plywood box, mount the rails there, THEN mount that box to the workbench, it would had been SO much easier)

closeup on one of the tenons, I think the original just used screws?, I wanted something sturdier since I’ll store tons of stuff as well, and it’s also pretty, I used a router and a template for this.

Another huge problem I had was that my printer was malfunctioning, damn you artillery

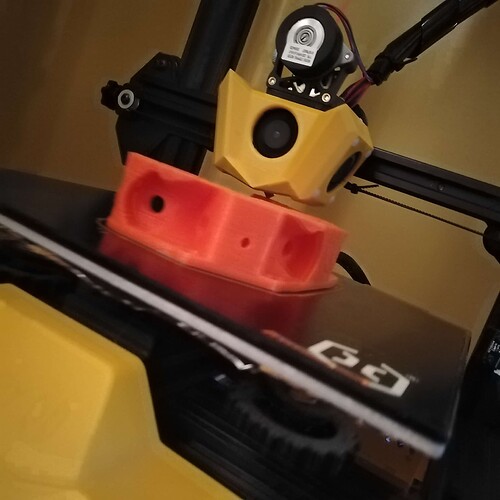

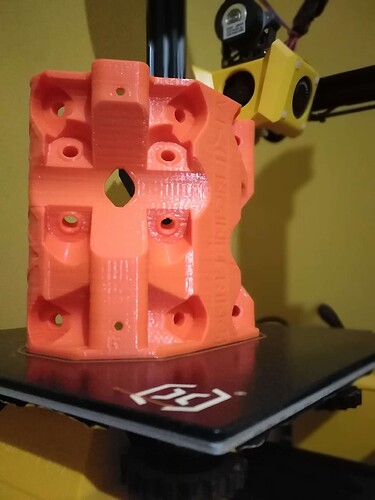

I was able to fix my printer by moding the machine, eliminating the problematic “aviator” boden cable and transforming it into direct extruder with a mini sherpa extruder, I also designed an adaptor for the mod to work.

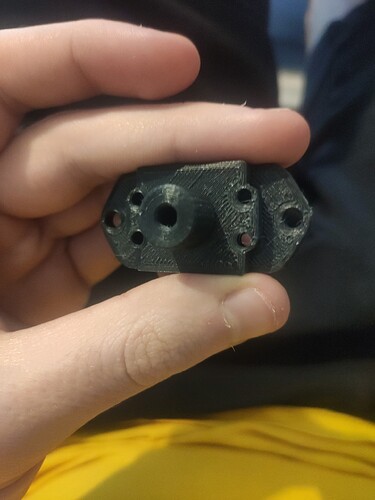

friend printed my adaptor design in ABS CF, it was wild to design something without any prototyping, but it worked!, he also sent me a mini-sherpa to replace my boden extruder

without the fix, I was able to print everything else, but I wasted half a kilogram of plastic attempting to print the core, I maybe had 5 failures?, all was thermal runaway caused by the faulty aviator cable, never get an artillery hornet, they suck.

4am, but success!!!

with everything together I started my build, I followed the wiki’s instructions excepting for the positioning of the legs, and oh damn it worked well

so I was hoping to share my method.

I have a background on guitar building, so precision fixtures is a common workflow for me, I need around 0.3mm precision in most hardware I install, and my personal consensus is “having to hold something by hand, position it accurately, then screw it down is a waste of time, it always move around like children on sugar”

One of the most accurate things we humans can do by hand is precision drawing, so, I made a drawing of the outer perimeter of where the legs should be, as precisely as I could with a meter long (40") steel ruler (I used the plywood top who was cut precisely as a reference), the MPCNC have legs designed so they can move a little for future adjustment, but we won’t need that!

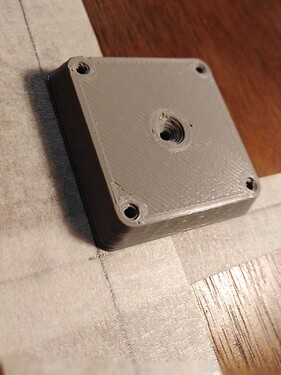

with my method, you don’t position the actual legs, you position the screw holes, and the drawing further aligns the pilot holes for the screws, I present you my MPCNC leg alignment jig!.

so once you position the jig, you make a pilot hole in the middle, screw it down, to avoid the fixture coming out of alignment while drilling, then use the holes for a 90° pilot hole for the legs, now the legs can be installed perfectly in place with the aid of the same lines I made before.

(I can share the file if anyone is interested)

now while screwing down the feets, I don’t have to fry my mind by holding something where I believe is the right place, just for the screw hole to be misaligned and the countersunk screw moves it out of square, oh yeah…, and since the holes are dead centered on the leg, the screw kinda centers the whole thing (the other way holds true as well, a misaligned screw, even if the leg has some “wiggle room”, will fix the leg in an uneven way, risking misalignment.)

end product?, the diagonals are close enough that my measuring tools are not able to tell the difference (carpenter’s measuring tape), and on the first try!

the legs are off by around 0.6mm the lowest from the highest, I think the workbench is more uneven than that, and shimming didn’t work.

then I followed the instructions to the letter, and in just one day I have most of the hardware done, excepting the core, the documentation has been super clear and helpful.

it’s been a CRAZY experience, but I’m really hopeful I’ll be able to pull this off!

what could go wrong?

any questions or something you want me to rant about feel free to ask!, I’ll post more or updates as I get them