Hello, I didn’t really know what to use for the topic. I bought the MPCNC in November and have been assembling it when i have free time and have had some difficulty without having any documentation or knowing exactly what to look for. But I have gotten my machine together and moving through various software and other means. As far as i can tell i have it wired correctly, built correctly, and setup correctly, however anytime i try to send any gcode file to the machine it does very odd things. I have used Fusion360 Cam , EstlCam , FreeCAD, Repetier(Host and server seperately), cnc.js on the v1pi image, and none of this seem to be properly sending the code to the actual machine. i was able to get the crown test to work but only when i manually copied the G code for it into a text file and saved as a .nc file and that worked flawlessly. I am not a total beginner to CNC and used mach3 and a generic cam program at my old job and never had an issue, on any of the equipment i used but this one is giving me a problem that I just cannot figure out and have been trying for over 2 weeks.

My setup(s) include:

RPi3 running v1pi to the Rambo 1.4 using Marlin and dual endstops.

my laptop running Estlcam to the Rambo1.4

my laptop running Repetier to the Rambo 1.4

i can hook the machine up however i need as long as i have the parts and some instruction. any help is appreciated, thank you for your time in advance. If you have any further questions i will gladly reply as soon as i get the moment.

What control board do you have?

We should start with the test crown, because we know that works on hundreds of machines. Let’s also focus on just one setup. Preferably repetier host from a laptop or the lcd screen.

Tell us exactly what you did and what turned out funny. We should be able to figure out which part isn’t right.

Then, we can move onto files created by estlcam and maybe someone can help is fusion if you like. I don’t use fusion myself, but can help with the rest.

I copied all that into a text file and changed it to .nc and that works just fine and is running on the laptop right now. when i use any of the other software it is creating extra lines and shapes inside the controller software and not getting past the first steps.

So far a gcode file converted to .nc with a text editor is the only means that work. i am using repetier host in my laptop.

It doesn’t work if it ends with .gcode? Or did something add a secret .txt?

Can you post some gcode that doesn’t work (preferably that you’ve tried and from estlcam).

Ok i just went and reinstalled everything and followed all the instructions on the page that you sent earlier and have resent that program to the machine using EstleCam and Repetier and that file is working with a pen and with a gcode format. So i seem to only be having issues doing 2.5D cam from fusion or when using CnC.js.

I will try to make a new file in fusion 360 and export it to get some gcode generated to try this way as well and let you know shortly. thank you

You can post the gcode, it at least the first few hundred lines in a txt file here and we might sorry something fishy.

Some other things to consider:

- Are you setting the zero coordinate before starting a job? The crown has G92 at the top to do that, but most gcode you make won’t unless you add that.

- Make sure your Z rapid aren’t too high. The new free version of fusion only does one speed, so you need to limit Z speed in the firmware. Estlcam can still set plunge rates on Z.

- The units in the gcode need to be in mm and mm/min. It doesn’t matter what your workspace is in, as long as cam is putting mm in the gcode file.

- The most common is for Z=0 at the top of the work, not the top of the spoil board. And pay attention to the clearance plane height.

I tried to add Gcode and the browser froze ill add a few lines like you said at the bottom. I did get a stl to go from fusion to repetier but that is acting like a 3d printer and says 8hrs to cut a simple square and circle in a 1/8" stock(tool-free). The file did correcting move to the center of my table like it showed on repetier though so progress, but the only way i got it to do anything is using cura slicer inside of repetier which is not correct i know, that would be for a 3d printer. the measurements were right, or close, though.

This is the gcode that fusion360 spat out:

: (PGM, NAME=“101”)

; MACHINE

; VENDOR AUTODESK

; DESCRIPTION GENERIC 3-AXIS

; T1 D=0.1 CR=0 - ZMIN=-3.675 - FLAT END MILL

: G90 G40 G94

G17

G71

; WHEN USING FUSION 360 FOR PERSONAL USE, THE FEEDRATE OF

; RAPID MOVES IS REDUCED TO MATCH THE FEEDRATE OF CUTTING

; MOVES, WHICH CAN INCREASE MACHINING TIME. UNRESTRICTED

; RAPID MOVES ARE AVAILABLE WITH A FUSION 360 SUBSCRIPTION.

M26

; 2D ADAPTIVE1

:T1 M6

S5000 M3

H0

G0 X128.035 Y-153.368

G1 Z15 F1000

Z5

Z2.65

X128.011 Y-153.354 Z2.649 F333

X127.984 Y-153.355 Z2.648

X127.962 Y-153.372 Z2.647

X127.953 Y-153.397 Z2.646

X127.959 Y-153.424 Z2.645

X127.979 Y-153.442 Z2.644

X128.006 Y-153.447 Z2.643

X128.031 Y-153.437 Z2.642

X128.046 Y-153.414 Z2.641

Y-153.386 Z2.64

X128.031 Y-153.364 Z2.639

X128.006 Y-153.353 Z2.638

X127.979 Y-153.358 Z2.637

X127.959 Y-153.376 Z2.636

X127.953 Y-153.403

X127.962 Y-153.429 Z2.635

X127.984 Y-153.445 Z2.634

X128.011 Y-153.446 Z2.633

X128.035 Y-153.433 Z2.632

X128.047 Y-153.408 Z2.631

X128.044 Y-153.381 Z2.63

X128.026 Y-153.36 Z2.629

X128 Y-153.353 Z2.628

X127.974 Y-153.361 Z2.627

X127.956 Y-153.382 Z2.626

X127.953 Y-153.409 Z2.625

X127.966 Y-153.433 Z2.624

X127.99 Y-153.446 Z2.623

X128.017 Y-153.445 Z2.622

X128.039 Y-153.428 Z2.621

X128.048 Y-153.402 Z2.62

X128.041 Y-153.376 Z2.619

X128.021 Y-153.357 Z2.618

X127.994 Y-153.353 Z2.617

X127.969 Y-153.364 Z2.616

X127.954 Y-153.387 Z2.615

X127.955 Y-153.414 Z2.614

X127.97 Y-153.437 Z2.613

X127.995 Y-153.447 Z2.612

X128.022 Y-153.442 Z2.611

X128.042 Y-153.423 Z2.61

X128.048 Y-153.396 Z2.609

X128.038 Y-153.371 Z2.608

X128.016 Y-153.355 Z2.607

X127.988 Y-153.354

X127.965 Y-153.368 Z2.606

X127.953 Y-153.393 Z2.605

X127.957 Y-153.42 Z2.604

X127.975 Y-153.44 Z2.603

X128.001 Y-153.448 Z2.602

X128.027 Y-153.439 Z2.601

X128.044 Y-153.418 Z2.6

X128.047 Y-153.391 Z2.599

X128.034 Y-153.367 Z2.598

Are you using guffys post processor for Marlin?

These gcodes are new to me: G17, G71, M26, H0. The M3 is backwards. So basically all of them seem wrong to me.

The G commands are using shortcuts to not repeat the G1, which is not normal for Marlin gcode. Feedrate is set globally to 333mm/min or 5.55mm/s. That’s a bit slow for XY and a bit fast for Z. I didn’t like fusion before they nerfed it, but now I strongly suggest estlcam.

The Z starts at 5, and goes down and looks like it starts cutting at 2.65mm from zero. That may be ok, but it is not how I set up jobs with zero at the top of the workpiece.

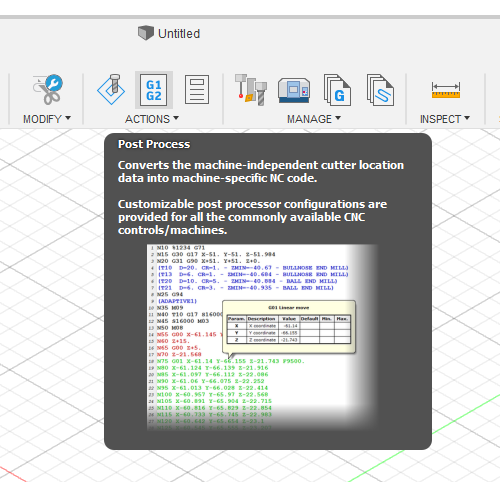

There is also a website ncviewer.com which will let you preview the gcode. That might give you an idea of what it is trying to do.

That is the first i have ever heard of guffys post processer.

As far as the G commands go I do not know what it is doing i thought it looked weird but haven never actaully analyzed gcode enough to know what everything was. This is probably the reason why my machine just beats itself against its Xaxis while moving up Y until i can frantically kill power.

I did export thta same file into EstlCam and it was odd for me since i hadnt messed with it before last week, but i may be able to figure it out with youtube and let you know later. i appreciate your help so far, it does sound like it is somehting wrong on my end so i need to fiure out what i have dont incorrectly and do some more learning.

@jeffeb3 Yup, seems like this is some wonky generic post, or maybe reprap?

Actually G17(XY plane selection), G71 (setting units explicitly to mm) and the M3 order should be quite fine. But M26 is definitely controller or even machine specific, H0 possibly aswell.

More or less off-topic:

Regarding Fusion I’m feeling the same way. When I heard, that they had restricted tool changes, I figured that’s not too bad, because most private users wouldn’t need that, anyway.

But putting such (sry, work life leaking in) brainless restrictions like limiting feedrates or removing rapid moves (although I guess one could circumvent that, if they knew what you’re doing) are… silly…

With a pro license it’s not bad, though. I have a pro license through work, but I wouldn’t spend the money.

Ever tried the FreeCAD CAM module Path Workbench - FreeCAD Documentation ?

Terrible to use at the start, and still had some bugs in adaptive clearing, last time I checked, but in principle you can do a lot with it, and it’s really free.

Well, first get the guffy post, here: GitHub - guffy1234/mpcnc_posts_processor: Marlin/MPCNC posts processor for Fusion 360

Download the zip archive and (at least I prefer it that way) put the files into a new dedicated folder.

Copy the Path of that folder from your Explorer address bar.

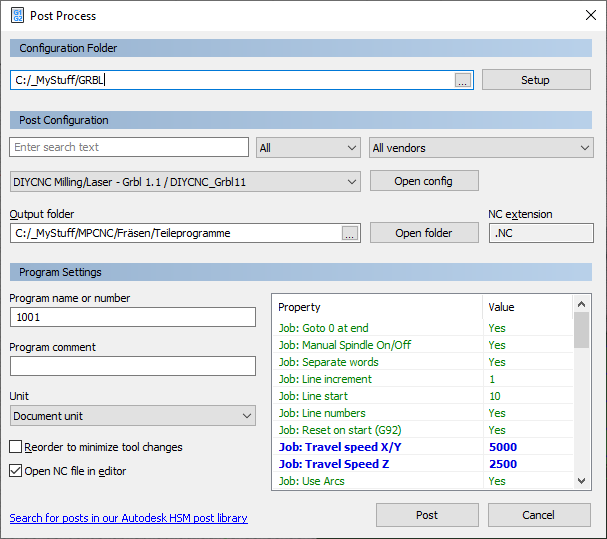

Open the post dialog:

Then set(or better navigate to) config folder to your new post processor folder(C:_MyStuff\GRBL in my case):

I’m using GRBL, but I guess you’ll get the gist.

Unless you want to use the posts provided by Autodesk, which probaby is not a good idea, as long as you’re new to this all, if ever.

Hope, this helps. If you need more help, let us know ^^

So i did add that to fusion as my post processor and sent the file over to my laptop and ran it in repetier but the Rambo board isnt recognizing it. I am trying a few more things to make sure have everything set up at each step properly, but repetier is still acting like i have a 3d printer setup

Nice. Can you attach the code file?

I usually use estlcam to process/transfer my nc programs, so that is something jeff or someone else would have to help you with.

But I can have a look at the gcode and see, if it should run, if the rest works.

Did you have a look at the v1 documentation?

Repetier host seems to be made for 3d printers and not for milling, so it might not be a problem at all, that it treats your MPCNC as a printer.

But I really dont’t have much XP with repetier host…

i just finished and got the code from fusion. but i cannot upload code since i am too new i guess but i will paste the first 50 lines:

;Fusion 360 CAM 2.0.9512

; Posts processor: DIYCNC_Marlin20.cps

; Gcode generated: Tuesday, December 29, 2020 10:12:22 PM GMT

; Document: Cam Test v2

; Setup: Setup1

;When using Fusion 360 for Personal Use, the feedrate of

;rapid moves is reduced to match the feedrate of cutting

;moves, which can increase machining time. Unrestricted

;rapid moves are available with a Fusion 360 Subscription.

;

; Ranges table:

; X: Min=24.295 Max=170.347 Size=146.052

; Y: Min=-193.993 Max=-41.188 Size=152.805

; Z: Min=-3.675 Max=15 Size=18.675

;

; Tools table:

; T2 D=3.175 CR=0 - ZMIN=-3.675 - flat end mill

; *** START begin ***

G90

G21

M84 S0

G92 X0 Y0 Z0

; COMMAND_TOOL_MEASURE

M0 Attach ZProbe

G28 Z

G92 Z0.8

G0 Z40 F300

M400

M0 Detach ZProbe

; *** START end ***

; *** SECTION begin ***

;2D Adaptive1 - Milling - Tool: 2 - flat end mill

; X Min: 24.295 - X Max: 170.347

; Y Min: -193.993 - Y Max: -41.188

; Z Min: -3.675 - Z Max: 15

; COMMAND_START_SPINDLE

; COMMAND_SPINDLE_CLOCKWISE

M0 Turn ON 11999RPM

; COMMAND_COOLANT_ON

M117 2D Adaptive1

; MOVEMENT_CUTTING

G1 X129.135 Y-154.393 Z15 F1275

G1 Z5

G1 Z2.65

; MOVEMENT_RAMP_HELIX

G1 X129.204 Y-154.308 Z2.646

G1 X129.267 Y-154.218 Z2.642

G1 X129.323 Y-154.123 Z2.638

G1 X129.372 Y-154.025 Z2.635

G1 X129.414 Y-153.924 Z2.631

G1 X129.448 Y-153.819 Z2.627

I’m too slow

what do you mean by “acting like i have a 3d printer setup”?

I have never used repetier before using it for this machine so i am not familiar with it at all but the only way i seem to be able to get the software to properly send the files to the machine i am having to use the built in slicer in repetier and then it treats everything like its being 3d printed. if i cannot get the gcode to function if i use the slicer it sends it right to the machine. idk exactly.

Ah. Hm… But you applied the settings from the documentation i linked to?

The GCode looks fine, in principle and should run IMHO.

Does it not do anything at all?

Or does it move to a XY position, then do one move in Z and then stop?

(When the controller hits M0 it will stop until you resume, usually by clicking somewhere).

You could also set up your Estlcam https://docs.v1engineering.com/software/estlcam-basics/

Then I could help you more directly. Or just wait until jeff’s around, again…

Maybe post a screenshot or two, of the issues you’re having.

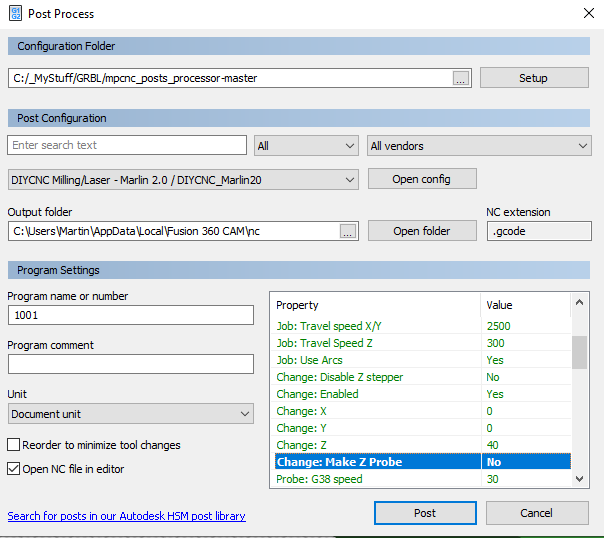

EDIT: Argh, are you using a Z-probe at all?

If not, switch it off in the post options:

But I fear that you’re missing some basic step, I’m not guessing correcty, or something with your repetier host might be wonky…

i believe you are right and i am missing a basic step. Its late now and i wont be messing with the machine any more tonight but i am looking at a video i found for fusion 360 cam for the mpcnc and trying to make sure i set up my files there correctly. once i get out to the shop tomorrow i will get some screenshots. i hope its just something i have easily missed. from everything i have watched the machine is so easy a caveman can do it and i am not doing so good. thank you both for all your help so far.

yep, sounds good.

yep, sounds good.

No worries! This is just sth you got to figure out once, and then you’ll be set up, fine.

Having been able to put the machine together, you’re already further down the road than most people!  gn8

gn8

Estlcam as a gcode sender doesn’t work with Marlin. Cncjs or repetier host is needed.

In RH, you will connec to the board, jog it around to the start, send G92 to set the 0,0,0 and then load the .gcode file and hit “print”.

This looks like it has M0 commands in it for tool changes. Those will need the lcd to clear in Marlin. It is also homing with G28. Which isn’t what you want either. There are probably settings in the pp to turn that stuff off, but I am not that familiar with fusion.

I use estlcam only for doing the CAM. It creates the gcode and I can load that in RH or cncjs.