I also posted my Fusion 360 Flyfischer beta PP settings here

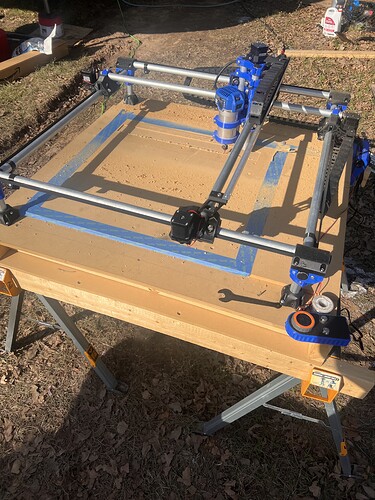

Finally “Electra” is in service! Did a facing operation, that I programmed in Fusion, with a 1/8” single flute carbide end mill. I was able to get cable chains installed, but I think I’m getting EMI induced from the router into the fluid dial RJ12 cable. I may get some shielding sleeve to protect it. Has anyone ran into the same issue?

Making chips surfacing this oak round. I had to raise the legs 2” to make this work better. Fusion played nice this time as I have gotten the hang of the design-manufacture-prepare- execute-observe workflow.

This hopefully will turn out to be a basic lion head within the face of the round. I’m waiting on a 1/4” single flute end mill and ball end mill before I get to carving though.

1/8” single flute end mill

3mm DOC

1.4mm step over

5000mm/min feedrate

0.125 feed per tooth

This is going to be my last entry for the “build” phase of my MPCNC. I’ll post individually for anything I add. I want to thank the community and the team for helping me get to this point so far, your helpfulness has been inspiring.

Today I went for it and cut out this lions head out of an oak round. Even though I had a cascading problem occur, I was able to save it once I saw what had happened. Basically, after the first step down was cleared out, the tool drove down in the lower right corner to begin the second layer of adaptive clearing, therefore going deeper than the plastic collar would allow. That caused missed Z steps, which caused my “bottom” of the model to get milled a little higher than intended. I paused and tried to raise z to rezero or re-probe, but couldn’t while in feed-hold. So I resumed the op until it lined up with the floor, paused, turned the tool off, loosened the tool mount, and lowered the tool ever so slightly. I resumed and it only missed the steepest parts of the next op “parallel” with a ball end mill to smooth things out.

I am proud of myself, yet I know I’m a very long way from being able to call myself a machinist. I have so much more to learn.

That is really amazing and nice save as well! Did you generate the gcode from fusion?

Some people do a circle, you do a full fledged 3D carve. Wow! ![]()

Yes, and there’s a lot I could do to improve the finish and decrease cutting time, but I did it without breaking anything, so I’ll take the win and lessons.

I watched the simulation a bunch of times, did a dry run with the machine only, then ended up missing the one thing that ended up almost ruining it. But again, I learned

And thank you !

Thanks for the help earlier, and I did a couple of test programs in foam and pine before this one just to be sure I knew what to expect.