Thanks for the gcode @Michael_Melancon! I put it in this morning and now its heating before it does anything else. I also left your 30s pause in there. My bed is 1/4" aluminum plate with glass on top of that. Let that heat soak in and give it just a little bit longer to hopefully stabilize before all the leveling starts lol.

My startup script is similar.

I heat up the bed first. I wait for it to get to temp. Once I get to temp, I set the nozzle temp. Then I immediately go into homing the axis. After homing x,y, and z, I do the auto-z level.

Usually by the time all the homing and leveling is finished, the hot end is up to temperature.

I do run a purge command that runs along the edge of the bed and then does the ‘swipe’ across the edge to wipe the nozzle.

I still do a skirt, but the skirt is usually more to give me a chance to make sure my microsteps are still set correctly fro the first layer.

I heat up the bed first. I wait for it to get to temp. Once I get to temp, I set the nozzle temp. Then I immediately go into homing the axis. After homing x,y, and z, I do the auto-z level.

Yeah I think with the thickness of the aluminum on my bed its better to wait a little longer to let it equalize better. Its working good now.

I do run a purge command that runs along the edge of the bed and then does the ‘swipe’ across the edge to wipe the nozzle.

I need to figure out how to add the wipe. With a .06 nozzle its now wiping across the print bed lol

I still do a skirt, but the skirt is usually more to give me a chance to make sure my microsteps are still set correctly fro the first layer.

Exactly! Luckily I haven’t needed to do much of that since I set the probe offset but its always nice to check

One day I’ll build me a nice printer with all these fancy features…

I’m still running a mostly stock 2019 Ender 3 Pro.

My “Wipe” is me with a pair of needle nose pliers trying to clear all the filament ooze as close as possible to before it touches the bed and starts.

And adjusting the dials by hand during the skirt.

And praying…

New head-canon for Mike while printing:

I’m still running a mostly stock 2019 Ender 3 Pro.

Didn’t the pro have a bltouch on it? If so you can do baby stepping z while its starting the print, or really any time

If im wrong its easy to add. And good practice before you dive head first into a MP3DP lol

No it didn’t. I bought this at the time where silent drivers weren’t a thing yet and TL Smoothers were all the rage.

BL Touch was still fairly new I think.

I looked at the CR Touch a bit. Every time I think about adding more stuff to this printer, I look at all these $200 printers that have all of these features and tell myself I’m not spending any more on it.

I was super into a Voron 2.4 when I found it, until I also found the price.

I really just want one with a bigger bed and a few of the new features. It serves it’s purpose now so it’s hard to justify the cost of a new one. I guess I’ll wait til this one dies.

I really want to be able to print more things, like TPU, ASA, etc.

Maybe when the time comes, you and @azab2c will have made it super easy for me already ![]()

Maybe when the time comes, you and @azab2c will have made it super easy for me already

By the time we get there @vicious1 will come out with V5 and we will all have to start over LOL

Looking for an advise for the source of material for bed and bed support. My initial plan was to order 1/4in thick aluminum plate for both bed support and bed but for the size if the printer I am building (325x325mm bed) that would require a 2x4ft blank and that is $250.

What you all use?

Is there a reason for the bed support plate to be metal? Bed attaches in 3 points close to rails so I would imaging all that strength is not needed?

Looking for an advise for the source of material for bed and bed support. My initial plan was to order 1/4in thick aluminum plate for both bed support and bed but for the size if the printer I am building (325x325mm bed) that would require a 2x4ft blank and that is $250.

I was able to go to a local welding shop and get it much cheaper than that. I just picked up another 48" x 60" piece of 1/4" and it was $280. So if you have any local shops around you stop in and ask if they have any drops.

Is there a reason for the bed support plate to be metal? Bed attaches in 3 points close to rails so I would imaging all that strength is not needed?

I believe most use 1/4" MDF or 2020 extrusion. I didn’t know any better and made mine out of 1/4" aluminum. If i had to do it over again I wouldn’t make that part out of the aluminum. Its so heavy that i had to drop the accelerations on the bed as it would skip steps homing/leveling

Thanks, curious why Z acceleration is important for homing? How bad it is?

Oh it didn’t bother me any to drop it. But it was just crazy to see it skip steps during homing

I am looking at the 1/4 MDF and thinking is might be too flexible. Anyone tried plexiglass?

I look at all these $200 printers that have all of these features

Ive bought two or three of those, and I can assure you they’re worth what you pay for them… one is still sort of assembled. Most are okay for about 6 months of my usage. I self.designed one that lasted 3 years. It still works, but I don’t use it much anymore, it’s getting picky.

My MP3DPv3 is still going strong. I did have to replace the CF rail (I used an aluminum square tube instead, and it’s good.) My v4 sees a lot of use. I am having bed adhesion issues with it now, but that isn’t the printer’s fault. It seems to happen now and again, maybe humidity?

A good printer costs more, but gives you fewer problems. I believe the v4 will be a worthwhile build for you.

Anyone tried plexiglass?

No, but came close… Tried Plywood and sheet metal (thin stuff found in HVAC aisle of big box store), but ended up going with Polycarbonate (Lexan) which seems less likely to crack/haze than PlexiGlass (Acrylic) exposed to IPA (something that’ll likely be used to clean the print bed).

Built my MP3DP mainly for the learning experience, and joy of it. My build would’ve been faster and cheaper if I kept it simple, and stuck to what others had already successfully done.

~Half of the things I experimented with ended up trashed ![]() (because of direction change), or failing

(because of direction change), or failing

![]() …

…

A good printer costs more, but gives you fewer problems. I believe the v4 will be a worthwhile build for you

I agree, but it’s still a hard value proposition when this $200 printer has been going strong for 4 years.

I have not had to even tighten the belts.

I’ve tinkered with it here and there, but really have had 0 problems with it.

My only real complaints are that the bed has often been just a little too small, and I really want to be able to do other filaments.

I do think a MP3DP is in my future. Maybe next year

My bed is 1/4" aluminum. My bed support is 1/4" MDF.

My build is here with all the choices I made

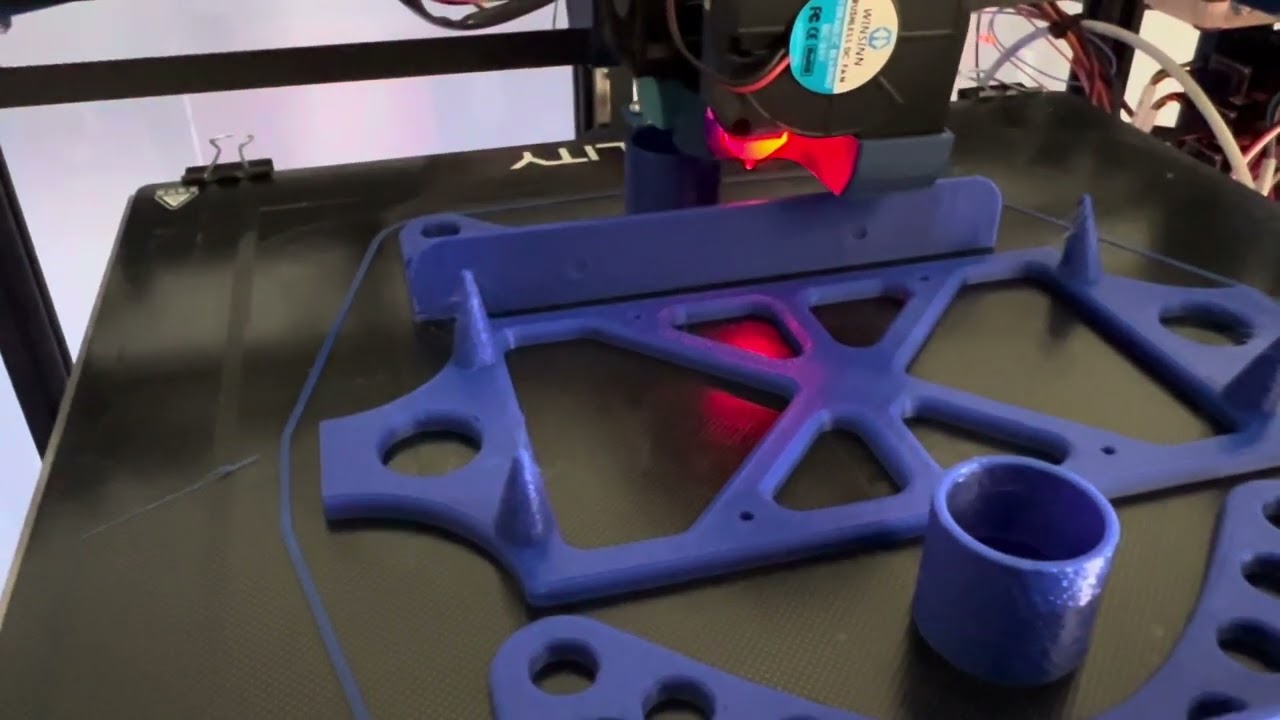

Can anyone help me understand why its printing like this? Is there some setting I need to change in the slicer?? I have printed this file a few times on various printers and never had it do like this.

Is it printing off an SD card?

The only time I’ve seen a printer act jerky like that is when a sender was struggling to stream the GCode or the board struggling to process it in time