I have my Primo at 24”x24”. Seemed to be a good size for me. The LR3 is 50”x98”. Funny thing is I used the LR3 to mill the aluminum instead of the primo. It’s just more rigid down low. I get a ton of chatter with the Primo that I just haven’t taken the time to figure out yet

soap and water to wash the pei as well. The alcohol won’t remove oils, just smear them around.

Dish soap. I use dawn on my heated bed to get the oils off and it really helps keep things clean so the bed stick is better. Washing frequency is once every 2-3 prints and it works fine. After every print works fine too.

It’s something about this batch of filament. I don’t have much left on the old spool, but it works OK.

I’ve used dish soap on the PEI, and IPA. This stuff (Overture PLA) just isn’t sticking. It’s the same brand that I bought for the LR3, but doesn’t stick. The PETg works great, even my 5 year old ABS was really good ion it, but this PLA just slides off. Worked fine on the blue tape so I’ll use up the spool that way.

Almost all of my PLA and PETG is Overture. Been happily using

https://www.amazon.com/gp/product/B079984GV5 on Creality Carborundum Tempered Glass. Am not running a print farm and just doing relatively infrequent prints. So, my ~3yrs of 3D printing is relatively inexperienced compared to folks here that are regularly churning out parts.

Seeing PEI beds referenced a bunch by MP3DP builders. I need to dig into understanding different bed material options, pros, cons… Curious if people have strong opinion on what works well for them?

I used to print on a pei sheet on my ender 5 plus, now however, I only print using blue painters tape on a carborundum tempered glass sheet with abl turned off.

The tape sometimes sticks to the object but is easily cleaned with hot water. The print is easy to take off the glass and I an print the next item in cue within minutes.

I have access to another printer that they use Elmer’s glue on to get stuff to stick. I’ve used blue tape and glue stick. I’d heard of hairspray and ipa wipe… Elmer’s school glue anyone?

Hairspray on my PEI sheet works great

Same here, I use a 3D printing spray on my PEI sheet and it can be hard to remove prints sometimes.

Dan, cheers for sharing the Drag Chain mounts, and Drag Chain size recommendation. Did you end up with 15x10 working out for you? Guessing you have bed heat, and wiring for 3 Z steppers fed through rear mounted drag chain (like Voron) ?

No, currently I have the heat bed, thermistor and 1 motor going through the drag chain, and the other 2 motors going through a braided sleeve. I’m sure that the 15x10 would work, but that isn’t how it’s running now. I’ll need to re-draw the mount ends for that, and of course unplug everything and re-run the cabling. Not an immediate priority, which probably means that I’ll get to it only if something major requires attention back there.

The 10x10 would have been OK if not for the thicker motor wire that I am using because it fits better in the fittings that the Duet 3 uses. They’re pretty beefy.

Just wanted to add a note…

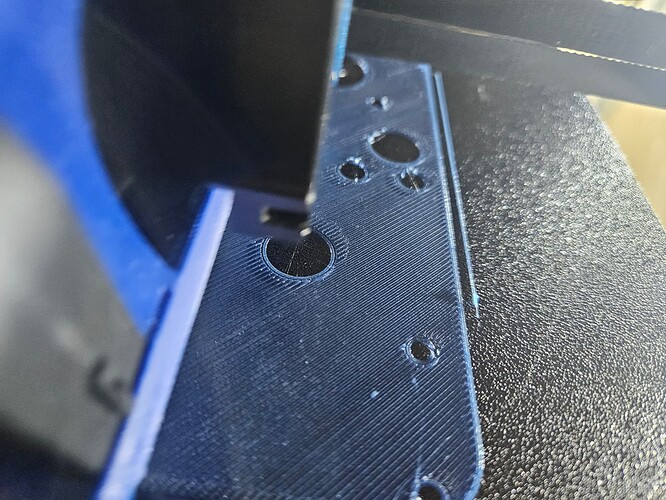

I knew that first layers like this were possible, but before this printer, I’d never seen one myself…

(Still a bit of mess on the interior perimeters at start/stop locations, but the infill is beautiful.)

That’s a good start, but it still has some visible issues. There’s insufficient overlap in the perimeters to the solid infill, so there’s some gaps where the perimeter of the holes meets that solid infill. Flow or layer height aren’t quite matched, and there may be some flow/retraction stuff going on as well.

Overall, that’s a very usable first layer. What did the next few layers look like?

The next layers are excellent, until it gets to the top of the infill, and does a bridging layer. I ran the job at 110% speed and forgot that it can’t really do that with the bridging solid infill, so that layer looked like a 5 year old scribbled over the top, but the rest of the layers looked great, and by the top, it was good.

Same part, finished with assembled hardware

Starting a new thread you might be interested in, Help develop the next MP3DP!?!