After reading some great updates from other community members, am curious about speed capability, and dimensional accuracy of my build…

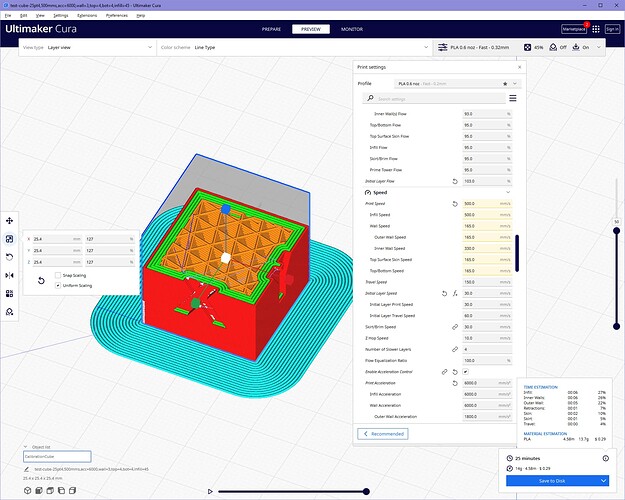

Currently printing 25.4mm calibration cube using same settings used to print Kobalt Blue Core for my LR3 Idex upgrade:

- 0.6mm nozzle, 0.32mm layer height, 3 walls, 4 top/bot layers, 45% infill.

- Printed Core with 120mm/s. Changed to 500mm/s, 1st attempt with 125mm/s initial layer didn’t even stick, so overrided to 30mm/s.

- This model is so tiny, and won’t save much time despite printer speed increase. I also won’t know/encounter failures that will likely happen when printing larger models, where the excessive speeds will become apparent.

Biggest bang for buck at this (or any) scale is using 0.6mm nozzle instead of 0.4mm.

Edit: 25mins displayed here is wrong. Cause is I didn’t override Minimum Layer Time to be smaller than the default (15s?). So, didn’t matter what Speed and Acceleration values I used here, the print speed ended up being throttled (slowed down) to satisfy the Minimum Layer Time constraint. Posted details in later 10/30 Post.