Just realized Octopus’s USB-A port can be used to power PI. Just don’t know if it should?

Don’t think that port is already needed for my setup, for example am not plugging SD Card reader into the Octopus’s USB-A since Klipper/Pi is orchestrating prints.

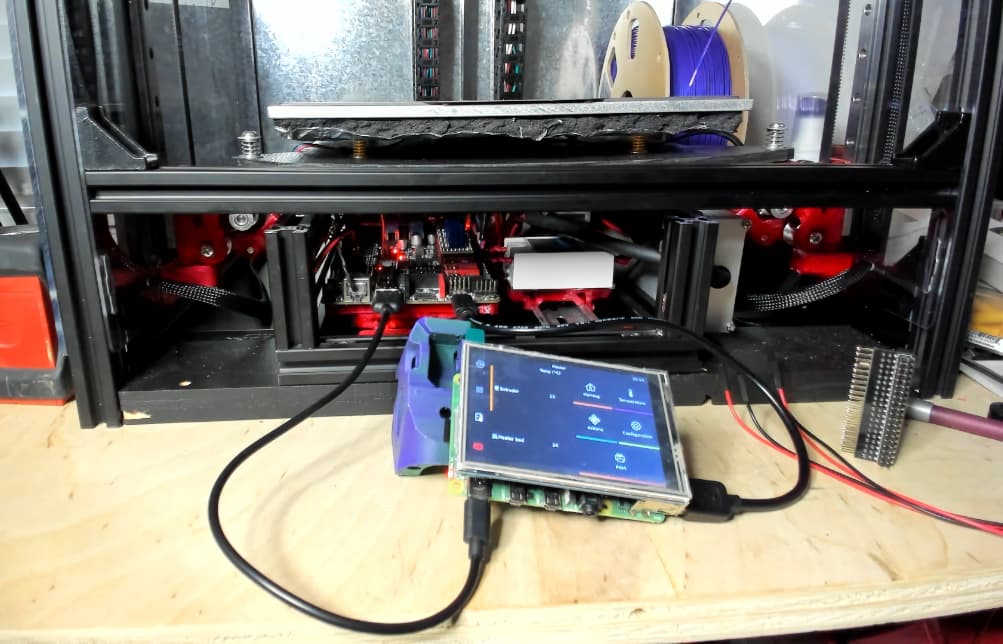

Was originally powering the PI via dupont wires between Octopus’s dedicated Raspberry Pi connector (J26), and the Raspberry PI VCC/GND pins on 20x2 GPIO connector. However, since the 3.5" TFT screen needs to connect to GPIO, in order to power Pi via GPIO, a GPIO splitter was needed (shown in the pic, discarded to the right). Looked at Octopus schematic, couldn’t see any electrically related pro/con connecting to USB-A vs J26?

Mounting a GPIO splitter worked, but made overall Pi + TFT assembly bulky. So am glad to be rid of that. However, I may end up reintroducing the splitter or similar if/when more of Pi’s GPIO needs to be connected.

Current plan… Ordering some USB cables with right angled connectors. Hoping to make wiring compact enough to be smooshed into a functional but decent looking front mounted panel/enclosure.

btw - the screen currently feels like a gratuitous unrequired feature since klipper can be accessed via PC/Tablet/Phone. Adding anyway since all the cool kids seem to have one. Maybe I’ll understand the utility/value better after using for a bit.

Update: 1’ USB C to A cables with right angle connectors seem to work. Just need to make a more appropriate mount…

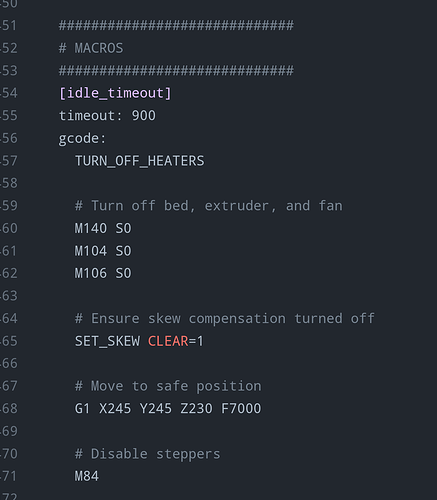

Am liking Klipper macros, for example can quickly configure a 15min idle timeout to safely park the bed just before motors are powered down. Without this, default behavior is for the bed to drop like a rock, unsettling, but doesn’t seem to break anything…

Still need to add separate macro to attempt safe park when config changes are saved, just before klipper resets, or maybe motors can be configured to hold position between reset (doubtful)?