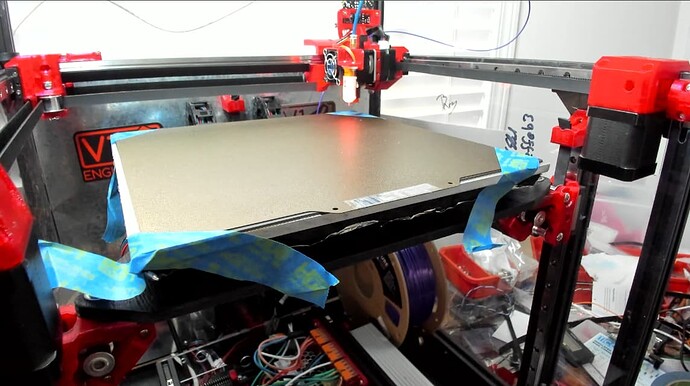

Was curious about impact of PEI on height variance while reading Jonathan’s topic. So, jankily temporarily taped PEI and magnetic layer to Alu plate…

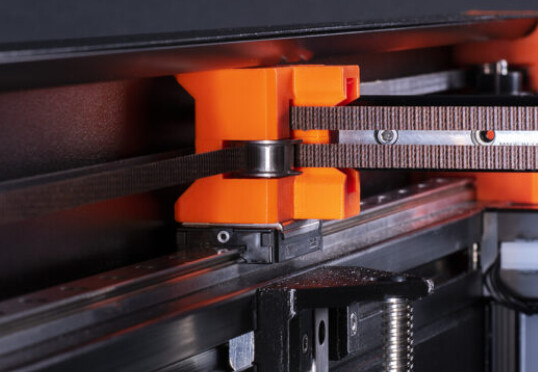

Used 4 point probing for z-tilt (instead of 3, details provided in earlier post), to help split the difference in my minor twisted setup…

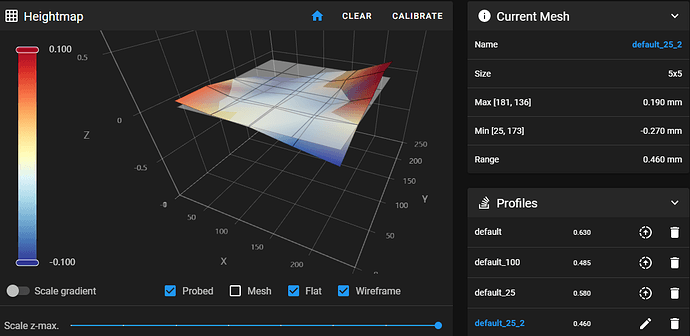

Not seeing much difference relative to previous mesh calibrations.

Measured extrusion diagonals between corners, looked the same to me using a regular mm based tape measure. Double checked extrusion is straight too. All looks good enough to me, leaving things as is and moving on. Hope this info helps someone.

Longer term, after seeing Prusa XL at RMRRF, am curious whether linear rails on top of the extrusion would enable easier shimming/adjustments of linear rails to easily compensate for skewed/twisted frame cuts/assembly inaccuracies? Could gain additional X width too, but maybe that approach would introduce other motion challenges?