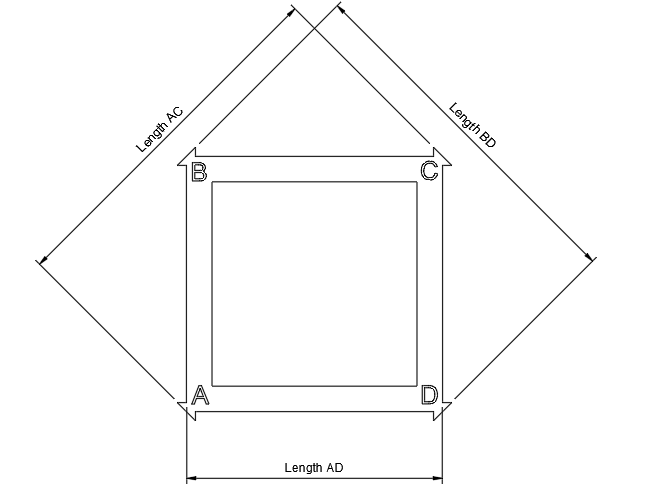

TLDR: get rid of the output power model section in the klipper examples.

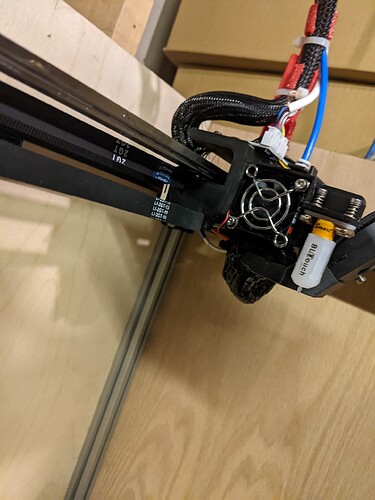

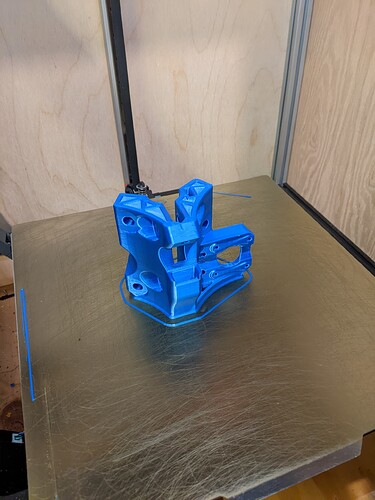

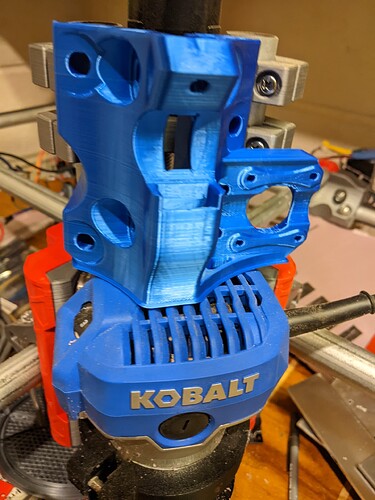

I have an adxl345

It is mounted above the hot end on the core and the X arrow and y arrow match the machine directions.

added

import adxl345.cfg

to printer.cfg.

adxl345.cfg is:

[mcu adxl]

# Change <mySerial> to whatever you found above. For example,

# usb-Klipper_rp2040_E661640843545B2E-if00

serial: /dev/serial/by-id/usb-Klipper_rp2040_E66038B713615530-if00

[adxl345]

cs_pin: adxl:gpio1

spi_bus: spi0a

#i2c_mcu: pico

#i2c_bus: i2c0a

axes_map: x,z,y

[resonance_tester]

accel_chip: adxl345

probe_points:

# Somewhere slightly above the middle of your print bed

150, 150, 390

[output_pin power_mode] # Improve power stability

pin: adxl:gpio23

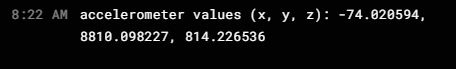

It is wired to a raspberry pi pico, which is connected to the klipper raspberry pi via USB. Not using rpi gpio because display is in the way. The 345 in klipper is set to communicate via spi:

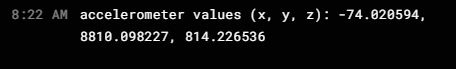

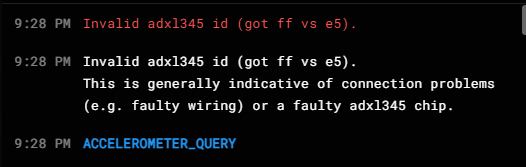

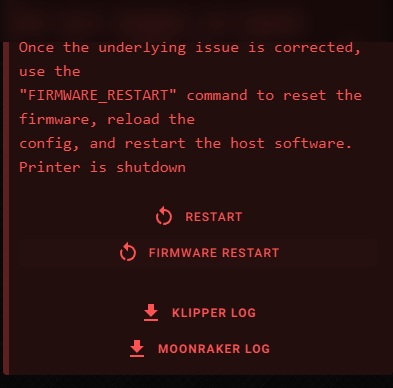

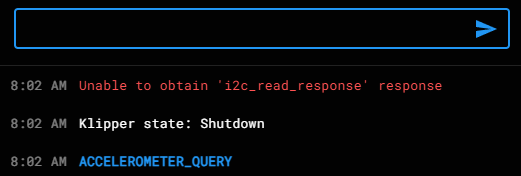

klipper reports:

which means something is wired wrong. The sensor is good because it streamed data on a different pico with circuitpython minutes before connecting it to Ernest, but it was communicating via i2c. It is possible that this chip has the SDO line pulled low to force it to communicate I2C. Need to get a meter on that line to see. The klipper error messages are not very helpful. The config file has been adjusted and the wiring verified… not sure what else to do here.

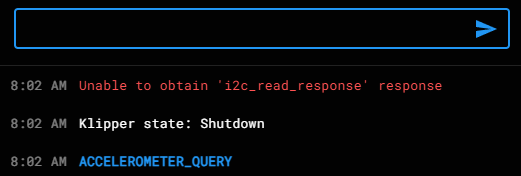

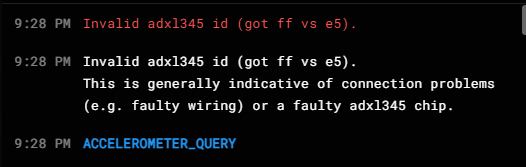

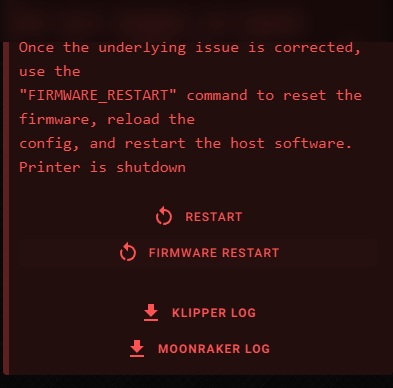

Another available option is an mpu6050 that communicates I2C (now “supported” by klipper), but the cfg syntax is wanting and the only example is the mpu9250, though they are all family chips in the mpu line, so it is implied that they communicate the same, but that is not explicitly stated. There is no valid [mpu6050] section allowed in klipper. [mpu9250] is allowed, but when running the ACCLEROMETER_QUERY, the system halts:

mpu6050 is called from printer.cfg so it can be easily commented out as one line and not a section. The mpu6050.cfg file:

[mcu pico]

# Change <mySerial> to whatever you found above. For example,

# usb-Klipper_rp2040_E661640843545B2E-if00

serial: /dev/serial/by-id/usb-Klipper_rp2040_E661640843363B24-if00

[mpu9250] # because mpu6050 is an invalid section

i2c_mcu: pico

i2c_bus: i2c0a

i2c_address: 104 #online docs say address is 0x68, but this is sometimes not needed. It doesn't work with or without.

axes_map: x,z,y

[resonance_tester]

accel_chip: mpu9250

probe_points:

# Somewhere slightly above the middle of your print bed

150, 150, 390

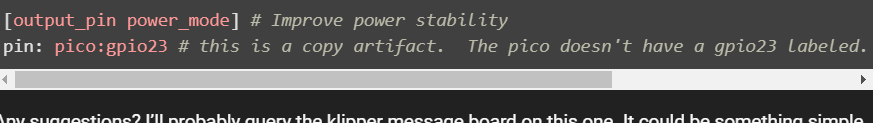

[output_pin power_mode] # Improve power stability

pin: pico:gpio23 # this is a copy artifact. The pico doesn't have a gpio23 labeled.

Any suggestions? I’ll probably query the klipper message board on this one. It could be something simple as is often the case. As I was typing this, one thing on the preview to the right stuck out:

so I tried it by commenting that line out: