I finished my one thing sooner than expected, so I did an initial test last night. I was printing PETG at 0.28mm, with the nozzle at 240 and the bed at 90. I decided to print the square that Klipper uses to calibrate pressure advance, scaled up to 200x200mm. My build area is ~235x235, so that felt like the right size.

I copied an existing profile in SuperSlicer, and changed the speed settings to look like this:

- Default speed: 150 mm/s. (percent speeds below are from this number)

- Perimeter speed: Internal 100%, External 62.5%

- Travel Speed: 150 mm/s

I also disabled machine limits in the slicer. I sliced the model with 0% infill, 2 perimeters, 3 bottom layers, 0 top layers. In Klipper, max velocity was set to 300.

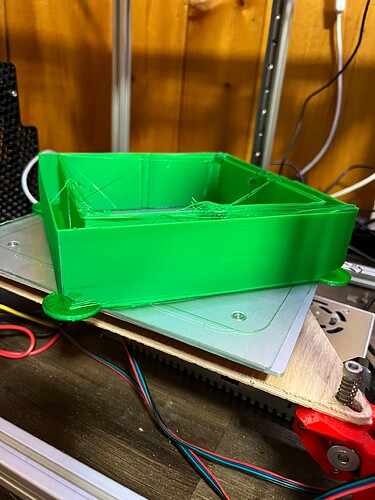

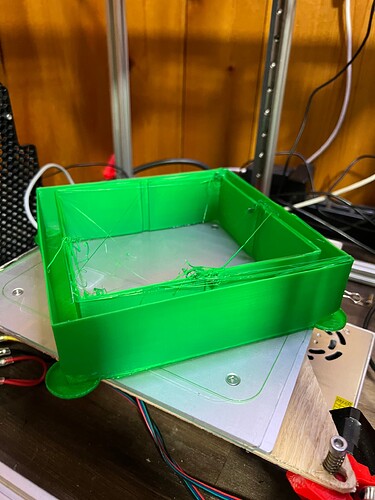

Once the 3 base layers were done, I increased the speed to 110%. I was seeing actual speeds of 165 mm/s for traveling, and around 83 mm/s when printing straight lines. 83 doesn’t sound like a lot, but it looked like it was flying. In the picture, the corners at the lowest layers look like absolute trash. I’m not sure why. Also the sides bulge out some. I suspect that is because I was using PETG with thin walls, and it’s often suggested to print PETG slower than PLA. But this is a test, right?

The corners cleaned up when I got up to 150% and I starting seeing print speeds in the low 100’s. When I kicked it up to 175% the corners look even tighter. Even at 200% things still looked pretty solid, and klipper was reporting back print speeds of right around 145 mm/s. I thought the damned hot end was gonna fly right off the rails.

At this point, the UI was telling me that I couldn’t increase the speed factor anymore because I had hit the limit configured in the printer config. I did find a way to change the printer config mid-print, so I kicked the machine limit up to 600 mm/s. Having done that, I set the speed to 250%. This is where things went off the rails. It was probably too big of a jump. I tried to bring it back to 225%, but by the time I got the change made, it had already printed 2+ layers. I think at 225% (so ~337 mm/s) the print would have held and been OK. Not great, but good enough for a prototype.

This is the first time I’ve ever tried something like this, and I pretty much guessed my way through it. Next time around, I’ll probably do some research to make sure I understand the slicer speed settings properly, as well as the klipper settings.

Update: The corners look so bad on the bottom because of the model. It was printing a corner in mid-air. The model obviously wasn’t designed to be scaled like that.