/edit: In case you didn’t notice, I really like fingerjoints on everything… ![]()

But it looks reeeaally nice!

Isn’t there enough photo, video, and information on the forum to showcase a primo or lr3 in 20 different color combos, various stages of construction and show projects and tool paths to illustrate what they can make and are capable of (drag races)? For an overview “community sponsored” marketing tool, it might be worthwhile to simply compile something from the galleries. My YouTube skills have plenty of complaints regarding poor audio, so I’m not likely to be nominated brand ambassador, but it might be a fun diversion to give it a try… don’t hold your breath.

I thought so too until I put one up. It didn’t look like something I spent $160 on for Baltic birch

I am doing my best to keep an eye out for unique and decent quality videos I can sprinkle throughout the site and shop. If you do decide to make something, make sure to post it here and tag me, so I see it.

Maybe have videos for every part so you can see their purpose in action? It does not add anything for a knowing user, but you can then watch a short video of what the touchplate does. Maybe even only a short gif.

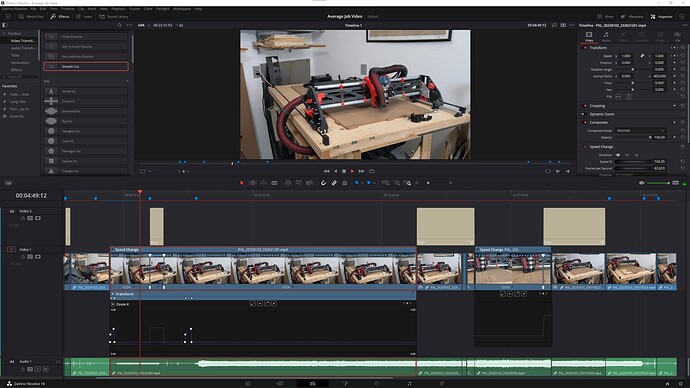

I have added Darwins touch plate video to the shop page, and I am editing a video now that shows me using it twice. This video is average job, start to finish. That should really clear things up. Time stamps will be added to highlight and link specific sections. I am just kinda stuck playing with all the settings. As I learn I keep changing things to improve it. So I should be done soon, or maybe not but I am still actively working on it.

On the video subject, it will definitely help to have the CNC showing in “unrelated” videos as a useful tool, once people see it, it sparks interest … On my last video mainly about making a board with the MPCNC, with most time not showing the machine, i had a bunch of people asking about it, i sent them all your way

Sometimes you just keep going down that rabbit hole… Started over a few times. Learned a lot, a whole lot. Need to add the text back in. Then add some sort of opening and closing screen or transition.

Oh, and some sort of background noise of some sort.

Sorry, this has been fun but it is tedious. Just when I think I am close, I learn something else.

If I find out anyone edits videos and I hear them complain about CAM…I will ring their necks. There are so many options. This is crazier than CAD, by far, real far.

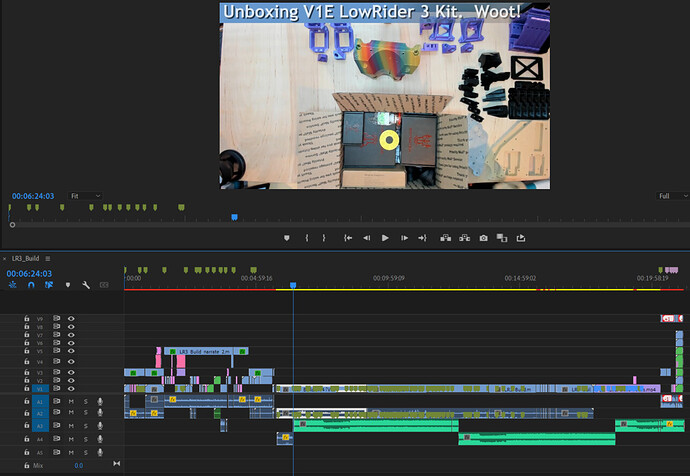

Yep, will get as deep as you let it. Probably spent as many hours learning/editing and futzing with Premiere as it took to build LR3. No idea how people churn out great content frequently. Curious to see what a professional sequence typically ends up looking like, here’s my mess (many of the longer green clips are nested sequences of clips)…

Lots of regurgitation of previously created video is how I do it

For background noise, Youtube as a free music library, so you’re sure to not run into copyrights issue.

https://www.youtube.com/audiolibrary

Still been hacking away at the list.

Rendering out a re-edited video, should be live at some point tomorrow. I will link it here.

No aluminum LR XZ plates anymore, less choices to make for the kits, and a bit less expensive for steel.

More complete LR bundle options…still needs work but less choices.

Updated the new domain, it is live but not public yet.

Have a new shirt design just about ready.

Published a RMRRF update the main page.

Been taking notes for a MP3DP BOM.

Made minor improvements to the MP3DP so I guess we will have aV4.1

updated the docs landing page

A few minor updates all over the docs.

Updated all the milling basics gcode section, separate LR and MPCNC

Peter has been working on a Kiri:moto guide, I just need to add a docs page

Added a few extra screws to the LR kit for board mounting

Made a new TFT case for M5 screws, TEsted, need to add to printables.

Started cleaning and consolidating the shop.

YEAH productive to the max!

Beast mode!

If they sell badly, you could also just have a note saying that they can be made by third party suppliers if somebody really wants them. I found a manufacturer in Germany for instance.

They sold okay but the Steel ones were $5 more, so a vast majority bought the steel.

And in the printed parts kits they were an option to add on, I think I might have sold 2 sets of printed XY parts, so now the plates are standard. Trying to make it easier, like everyone is suggesting here. Now I need to work on the descriptions and stuff.

Video is up.

Interesting, I had the option to go steel, but I chose Aluminium because it can’t rust. ![]() Stainless steel on the other hand…

Stainless steel on the other hand… ![]()

…is a lot more than aluminum. Also looked into powder coating, not as much as aluminum but well see if there are any complaints about paint/prime.

You were out of plates when i needed mine so i had a local shop cut them out on a water jet. (twice as much as your plates btw). They came directly from the water jet to me. I sanded them and sprayed with metal primer. then brushed on 3 coats of paint that matched my printed parts. in less than a week it was showing small signs of rust. Florida humidity isnt friendly at all. Thinking about taking them off and putting them in my dads blast cabinet and have a friend power coat them for me. We will see how bad they are when i get back in town after its sat for 2 weeks