It’s now at the doing something useful stage.

Congrats! That has been a heck of a project. Looks like it is working perfect, and how cool is that unique sound!

Thanks, it’s getting there, it took a while for my dumb ass to realize I was trying to spin the servos faster than the data sheet said they would go.

But once I did the math (doh!) to know the limit’s it’s behaved itself.

I don’t have any decent pictures of the results yet, I’ll share when I have.

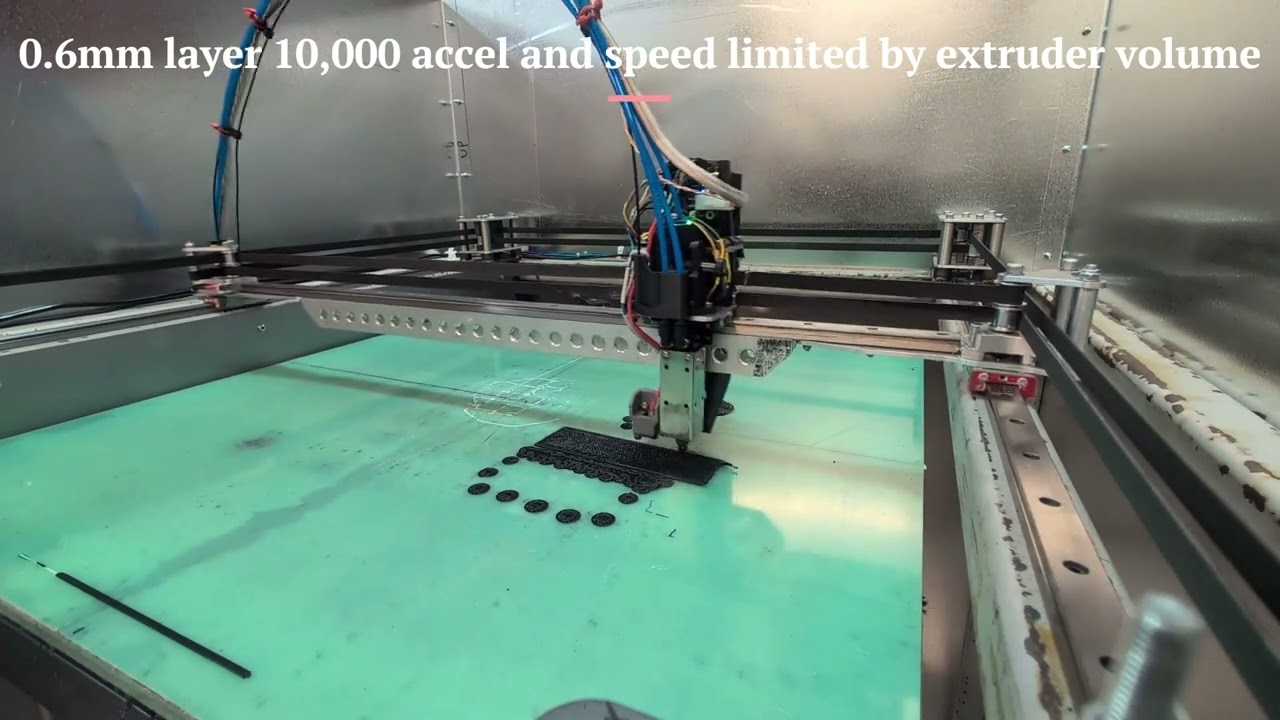

I thought I’d give you all an update on where I’m at with this.

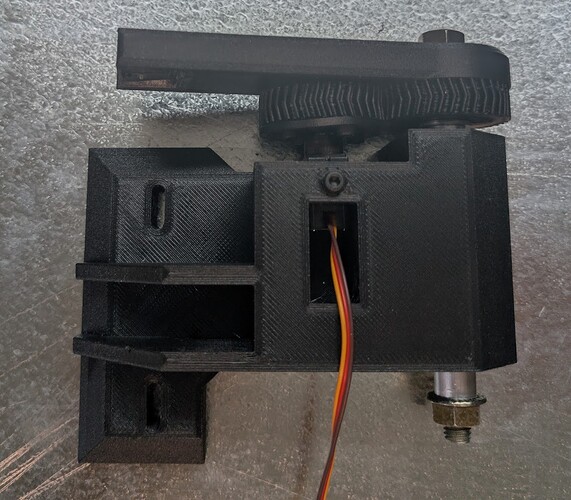

The servo arrangement for the Klicky probe was changed to this:

Which has proven to date to be much more reliable, the arm spins on a pair of roller skate bearings in true MPCNC style

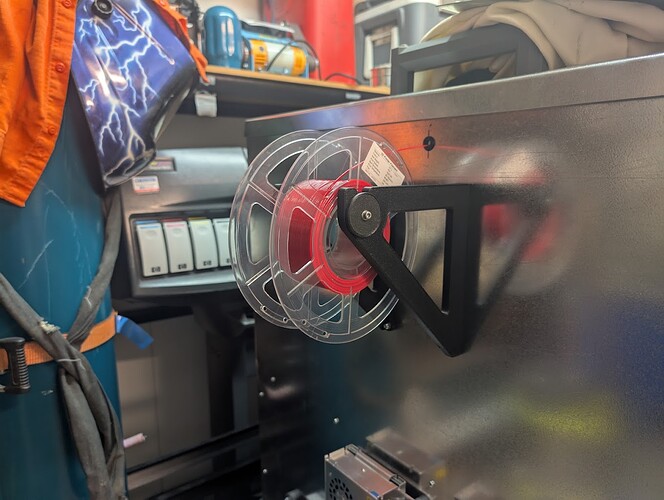

Where I had the filament going in at the bottom of the machine was not working so I did this:

Which is crude but so far has worked very well.

I realize I’ve not photographed it, but the machine is now enclosed in steel panels.

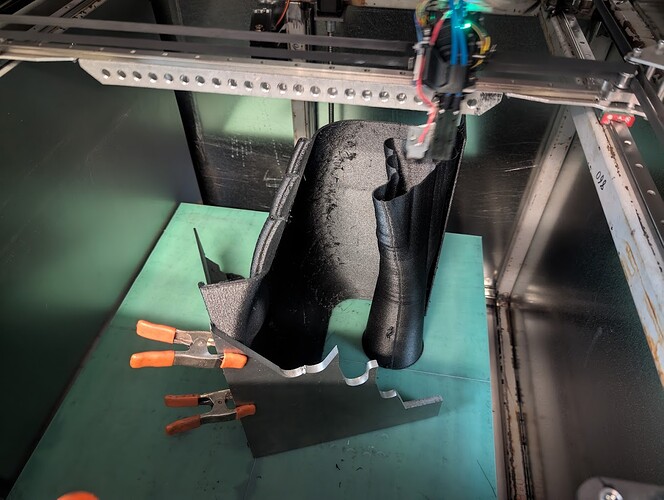

I’ve been doing a bunch of test prints and smaller stuff, but eventually I need to get on with trying to do something big, as I realize the issues that show in doing big stuff are different to doing small stuff. So this is the first big ‘real’ thing off of the machine:

2L coke bottle for scale.

The aluminium plate was clipped there during the print as that side was flexing too much.

The final part weighs 1.7kg and there’d be another 200g or so in the supports. This was printed in 14 hours.

Looking at the part there’s some settings still to work out:

There’s stringing to resolve and the supports won’t separate

About halfway up there’s a change in colour due to the spool change. the horizontal line a bit further up is from where I clipped on the plate to stop it wobbling.

But as far as I can see, I see no Z wobble or similar artifacts.

The part is use able as is, so we carry on, I’ve some ideas on settings to play with though, hopefully without losing any speed.

Dang that is a huge print! Congrats, looks like the only thing to work on is slicer settings, that means you made a heck of a printer.

So what us that giant thing you printed? Looks like you could print car bumpers and mirror mounts… Or darth vader helmets.

The part in question is the ‘real’ version of the orange bit from below:

Which was a prototype done on normal size machine a few years ago, I forgot to say the new part is in PETG-CF.

I realize now the major source of the current issues is part cooling, nowhere near enough of it. I’d planned on mostly printing stuff that didn’t need cooling but at that time I’d no experience with PETG which I realize doesn’t like being printed enclosed (The 1.5kw bed heater is keeping everything too toasty in there) and fans on the hot end are far too small. I’m going to test this theory next.

I’ve got a blog on the overall project at: 28 March 2025. It’s been a while… | 1TG - Design & Build of the One Tonne Guerilla that I keep up on a random basis, if you’re wondering overall what the heck I’m up to. This project is why I built and MPCNC in the first place.