So I’ve played with a couple different cutter holders and all of them are too floppy in x and y. I can see them flexing when running a cut. What’s everyone’s experience with cutting vinyl?

I think you might be well off with the one Doug created.

That’s the last one I’ve been playing with. Also tried the one that zip ties straight to the router body. They both are basically the same compliant mount.

Hmm, then I am out of ideas. I know, that was fast… ![]()

I used the one I made.thst ties.to the router.body with success, but it is a bit picky that you do not press hard on the vinyl. Light pressure, and it is stiff enough.

I did make a completely overbuilt one that holds the drag knife body enclosed in a 65mm shell, and then spring loads the drag knife downwards. I found it very tricky to fine-tune the body of the cutter to exactly size to the drag knife, and just barely allow it to float, but not to wiggle. That one fit into the LR2 using the Makita router body… I never did publish it as a printable, because it was too picky. I had re-planned it based on a milled design. 2× 65mm circles, with a 14mm hole in the middle, milled from 12mm plywood or MDF and flued together to hold the drag knife, and one more to hold a spring?

Wait… no good, the drag knife needs.to extend downwards from the router body position… still.I bet I can do this with better repeatability with milled wood…

Reading, watching.

Do I have the CAD up for mine? Which machine do you need it for?

If I make the arms wider, not thicker, it should add more XY stability…that does start to add to the “spring” to make it stiffer though. If you look at the ones I bring to the shows, those are one or two layers thick in the spring, and a bit wider. But you probably need the CAD to dial that in for your printer.

In the LR3 printables pen mount you will see I have a few versions to try and get just the right stiffness and rigidity.

Trying to run this on my lr3. I’ll take a look at the pen plotter parts.

Hmmm, I need to find the CAD. Printables there is a .9 and a .6mm thick arm. I use the .6 for a pen and a .9 for the cutter.

I can make a wider set for you or send post the CAD.

I think that would really help. I also have one that mounts directly to the core instead of the router. That should be even better.

Better one,

Pen mount Deluxe.3mf (24.5 KB)

Wire holder.3mf (25.6 KB)

I have not saved these in printing orientation so the bendy arms should touch the table.

Yeah with a one wall arm you need to mess with slicer settings to get that right, it will work though.

But that is more for a pen, if you are suing a drag knife 2 walls is probably better.

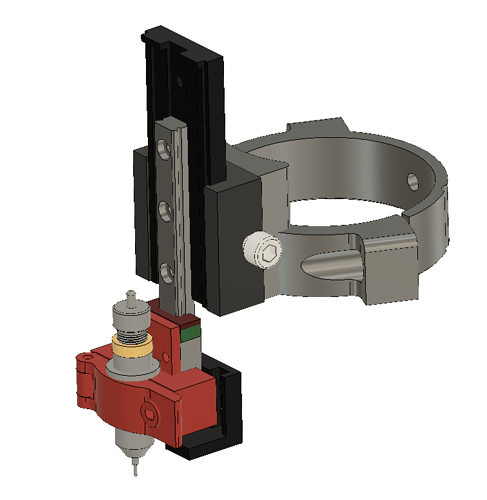

I am in contention for the slowest LR3 build ever, but have been working on a provision for a pen / drag knife along the way. The concept I am moving forward with was to integrate a feature in the router clamp that I attached a Neje laser mount (A40640) clamp to and then built a pen/knife attachment that could easily be installed into that laser mount.

Independent of how it is attached, I am trialing a design built around an 100mm long MGN9C linear rail. It has a spring loaded clamp for the tool and a light pressure spring to give a some resistance to the vertical float beyond its own weight.

I have finally established motion with my LR3 (after starting about a year ago) and made a test crown with a Sharpie a couple of days ago. It worked well enough that I’m going to call it good enough for me.

I can share the design if anyone is interested - the only real downside was the $17 rail, but that’s still $$$ less than my wife’s Cricut and my workspace is easily 50x bigger, so I coughed it up.

Absolutely!

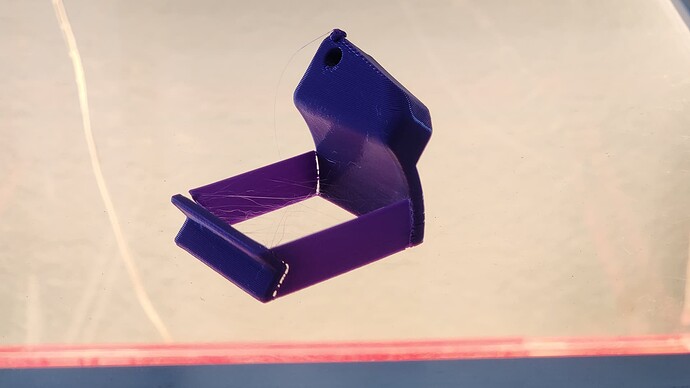

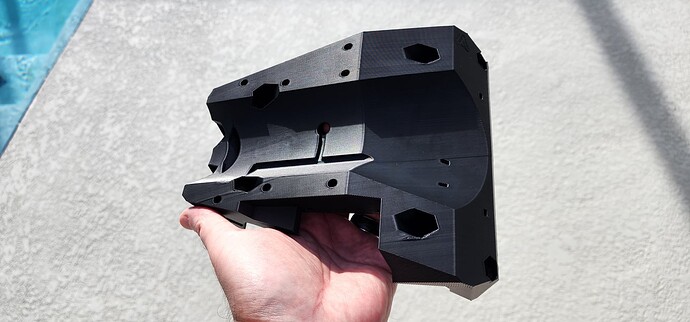

Okay, lets start with a couple pictures. If I figure out how to upload it somewhere I’m sure someone can refine it:

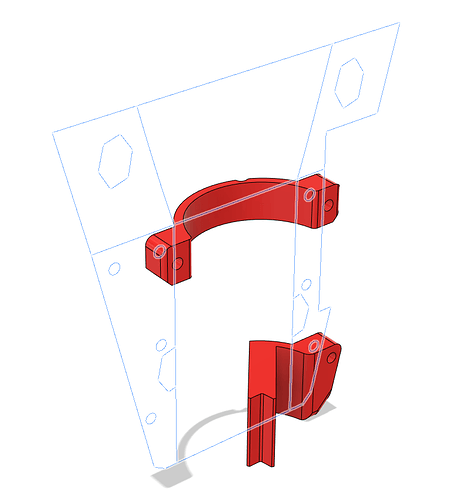

Lots of black parts though, so here is the cad model:

There is a feature in the mount to lock the drag knife from sliding up in the mount.

I didn’t buy any springs - I just used what I had laying around. There is a screw running through each so the pre-load can be adjusted.

Nice! I’m having to reprint the core because I spun one of the nuts that holds the bottom dust shoe in place.

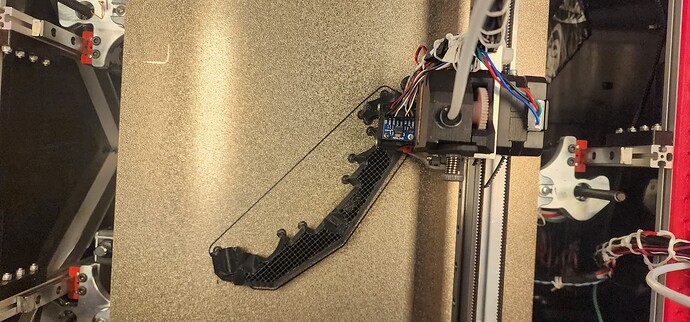

Testing it in HIPS because I’m out of PLA and am impatient. ![]()

I think it will be fine!

welp, new drag knife mount kinda works? I think my issue is the blade rotation. I guess what I’m trying to cut is too fine and the difference between where the last cut stops, and the next starts can overlap.

Also took this thing apart and put it back together about 5 times this morning. ![]()