That speaks words to me.

That’s something I didn’t account for.

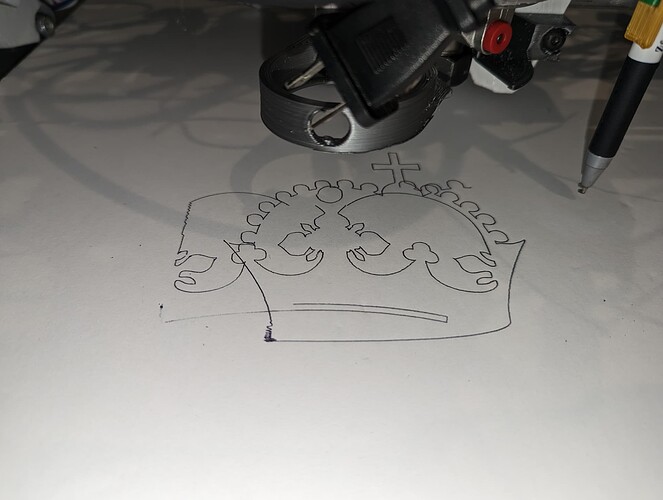

From my start I done thee crown art without this issue I simply left it 1mm from the stock and press print that was it here’s the results from that test run.

Now Im having the machine bottom out and I’m still not certain to what exactly is going on how can I go about of getting this corrected ?

Please tell us more info of what you mean by bottoming out?

Possible causes I can think of:

- Z height not homed to the top of the material properly

- Loose grub screw

- Table not flat

- Drawing intended for one pass, but more than one pass (with later pass at deeper depth) got programmed. (I think we ruled this out.)

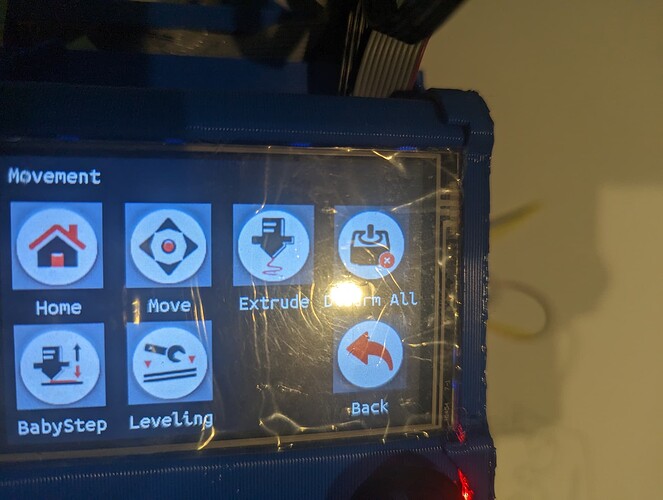

I’m checking my program settings and I’m using a skr pro so I selected the Marlin program

The machine does not even get to run before any commands are done.

It just starts to bottom out of I send this to you you can have a look at it when you get a chance.

I just don’t know how I would send the gcode

That image was my first try for the crown you can see my starting position and how it came out besides there was an update that I’ve just done but I’m just very unsure of what the problem is if I’ve done everything that doesn’t seem to occur when doing the troubleshooting.

If so please let me know.

This is on my second attempt but I’m not getting any results

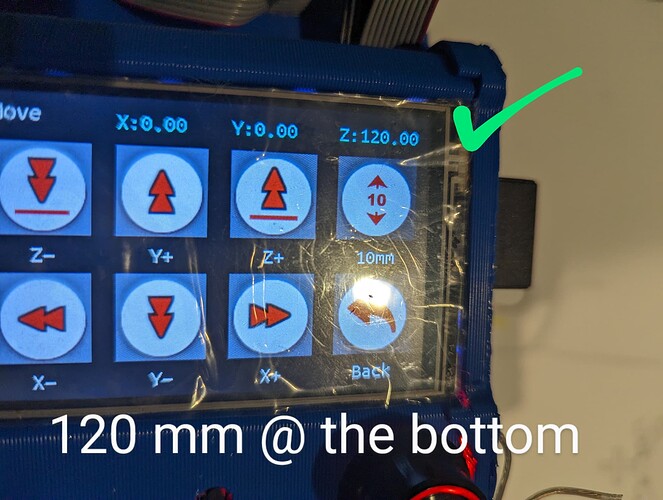

Are you setting your Z height with the pen’s tip on the height of the paper? or close? If you “move” the LowRider 3 to Z height = 0, the pen should be resting on the paper with a light pressure.

Correct just above the paper

When I asked “Are you setting your Z height…” I am referring to “zeroing” the Z at the correct height, which should be an option on the TFT under the “Home” options screen.

OK. So in the short list I thought up…

- Z height not homed to the top of the material properly. (We’re sure this is not it.)

- Loose grub screw

- Table not flat

- Drawing intended for one pass, but more than one pass (with later pass at deeper depth) got programmed. (We ruled this out.)

Could you explain, exactly what you expect to happen, and what happens instead?

Nothing has moved since my last sketch also I’ve move the z axis and they all reach and touch the end stops but please I’m listening to instructions

ARE we sure this is not it?

It’s not enough just to move the CNC down to the right height. Once you do, you must click on “Home” screen and tap the “Zero Z” button, to tell the machine that’s the new 0 for Z.

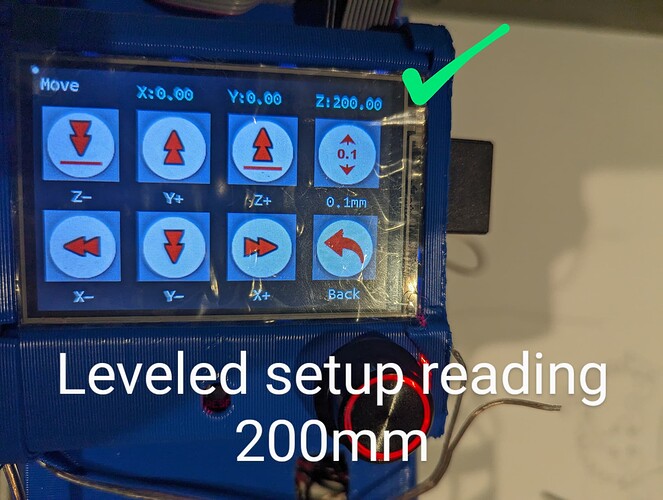

Okay you literally have to let me know where z zero must show . Here’s what I did I hit home and for the zero axis

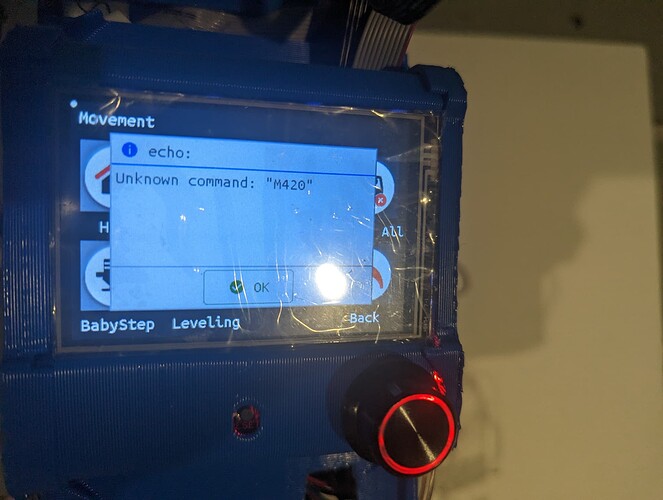

Ugh. This is now the second time today I’ve read about someone hitting an error of “Unknown command: M420”! Please check out the discussion beginning at the link below, and continuing onward. (Hint: they are still working on it!)

Okay thanks

OK, so for info for future sake, assuming you were not getting the M420 error when you home…

The normal workflow is:

- Home the machine Z

- Home the machine XY

— these two steps get you to the machine’s 0,0,0 origin, which is likely not the “work piece origin” that you need for a cut job.

- Move the CNC’s tool head / bit / pen tip in the X and Y axes to the desired location for the “work piece origin” (the 0,0 you need for X and Y for the cut job).

- Zero the X and Y at that new location.

- Move the Z height down until the tool tip is on the top of the material.

- Zero the Z at that new location.

- Optional: Raise the tool up by about 10mm or so for a safe height for XY movement.

- Optional: Turn on the router/spindle (if needed for the cut).

- Start the cut.

Okay will do I will have to wait for the solution for the problem to be solved I appreciate it

You can just disregard the error, I don’t think it will affect anything. We will figure it out, just not sure why it is happening.

@sway1 : So, can you just tap “OK” and then get into the Home screen’s options? If so, you could go ahead and try to do the workflow I typed above.