I vaguely remember that now. I guess the belts will let the bed drop easier as well. I’ve only had one power recovery print so far. With our printer since the bed doesn’t move when the steppers lose power, we assume the z hasn’t changed since the last layer, so we only have to rehome x and y.

Yup the belts let it drop a bit. I haven’t had a power outage in a long time so I kinda about that feature.

Here’s my G34. Is this normal?

13:10:35.722 : G34 Iteration: 1

13:11:08.485 : Z2-Z1=1.17 Z3-Z2=0.07 Z3-Z1=1.10

13:11:08.831 : G34 Iteration: 2

13:11:40.921 : Z2-Z1=0.42 Z3-Z2=0.06 Z3-Z1=0.36

13:11:41.179 : G34 Iteration: 3

13:12:13.668 : Z2-Z1=0.21 Z3-Z2=0.11 Z3-Z1=0.10

13:12:13.791 : Decreasing Accuracy Detected.

13:12:13.910 : G34 Iteration: 4

13:12:46.399 : Z2-Z1=0.05 Z3-Z2=0.27 Z3-Z1=0.22

13:12:46.512 : Decreasing Accuracy Detected.

13:12:46.642 : G34 Iteration: 5

13:13:18.989 : Z2-Z1=0.03 Z3-Z2=0.10 Z3-Z1=0.13

13:13:18.989 : Decreasing Accuracy Detected.

13:13:19.228 : G34 Iteration: 6

13:13:51.685 : Z2-Z1=0.11 Z3-Z2=0.15 Z3-Z1=0.26

13:13:51.686 : Decreasing Accuracy Detected.

13:13:51.816 : Decreasing Accuracy Detected.

13:13:51.936 : G34 Iteration: 7

13:14:24.422 : Z2-Z1=0.37 Z3-Z2=0.36 Z3-Z1=0.01

13:14:24.423 : Decreasing Accuracy Detected.

13:14:24.556 : G34 Iteration: 8

13:14:57.048 : Z2-Z1=0.06 Z3-Z2=0.07 Z3-Z1=0.01

13:14:57.161 : Decreasing Accuracy Detected.

13:14:57.274 : Did 8 of 8

13:14:57.274 : Accuracy: 0.07

Yes and no.

Sometimes it misses and uses up all 8 tries. 0.07mm across your bed is still great.

Things you can try to get that better is, make sure your BLT touch is in the correct offset range, make sure there is no external forces on your print head. Filament is not pulling on it, wires are extremely free to move, the block itself is not sloppy loose, and most important that we just found out that Z belt tension plays a significant role in this. It needs to be fairly taught to get the subtle movements in. Too loose and it does not adjust as well as it could.

If it always takes 8 tries, something needs to be adjusted. My typical is 3-4 tries and then it is within range.

I hardly ever get the “decreasing accuracy” message now, but I had a bad time of it for a while.

One of my Z belts wasn’t tight enough. I had moved some stuff around, and one of the belts was loose. Not enough so that it was terrible, but just not quite tight enough to get accurate enough motion. It was just one, but it did some really wonky things. Once I tightened up the belts, it has been all good.

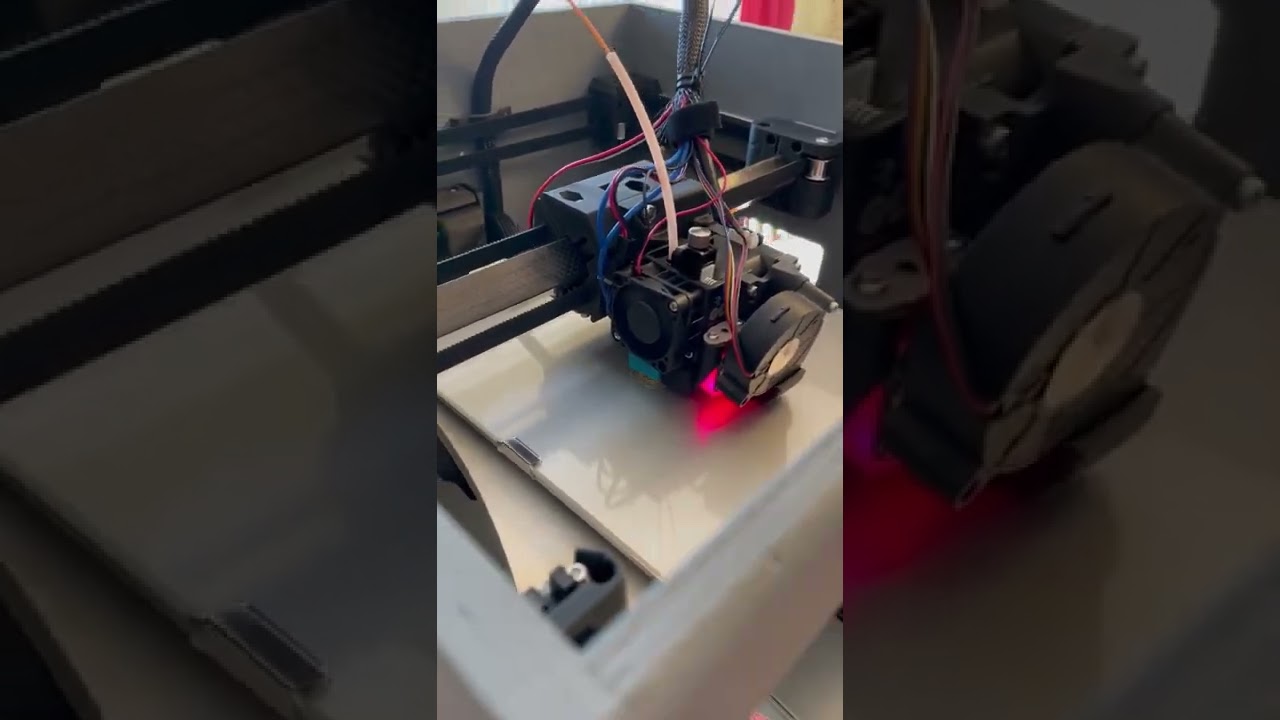

Alright, slow moving progress on this. I have everything moving properly so now time to try printing something. The first thing I did was check the Estep calibration. I measured how 3in on the filament and put a mark and extruded 3in and it was spot on. So that’s good. Time to try printing.

Here is how the print turned out. Not great. Seems like it is severely under extruding. I use Cura as my slicer and Repetier as my interface with the machine. Is there anything I should know? Does anyone have recommendations or suggestions as to why this is performing this way?

FYI, this is PLA running at around 225deg hotend and 65deg bed temperature.

225°C seems to much for PLA, especially looking at all the blobs and the bi-color print. That caramel color looks like an overheated white filament. I would try 195°C/200°C.

Also your first layer doesn’t look to be pressed enough on the bed, you should try to level your bed a bit closer.

Edit: I see you have a BL Touch attached, have you done the automatic Bed levelling, and does the mesh is load at beginning on your Gcode ?

Is it possible you have the filament diameter set to 3.0mm instead of 1.75?

Good call! Just checked and it was set to 2.85mm filament. I would have figured 1.75mm would be default so I never thought to even check that. Hopefully that changes things a good bit. I would think it would. Might be able to test it later, might have to wait until tomorrow. Ill let you know if that helps. Thanks a lot.

The filament color is orange so I don’t believe im burning it. I run 225C on my Ender 3 with PLA so I think it should be fine. If I still experience issues I will try coming down on the temp and see if that helps. Thanks for your input!

These thermistors are pretty good from a relative perspective (5C higher is close to 5C higher). But poor on absolute (a nozzle at 220C could be 210-230C on the sensor). They are consistent though.

Given that, I wouldn’t assume the same reading will be the same on different printers. They each need to be tuned. I wouldn’t worry about it just yet though.

After changing my filament diameter to 1.75mm I had immediate success! Here is my very first print on the MP3DP Repeat. Overall, I am quite pleased with the first print. Now just to tune it a bit.

I am not sure what caused the odd lines on the vertical pillars on the boat cabin. Ill have to tune things up and print again to see if its a common error.

I am still getting “decreasing accuracy” on my G34 but I let it continue with the print anyway and it turned out fine. This was small footprint print so it didn’t really pick up on bed unlevelness to much anyway. I think I need to tighten up the belts a bit and see if that helps.

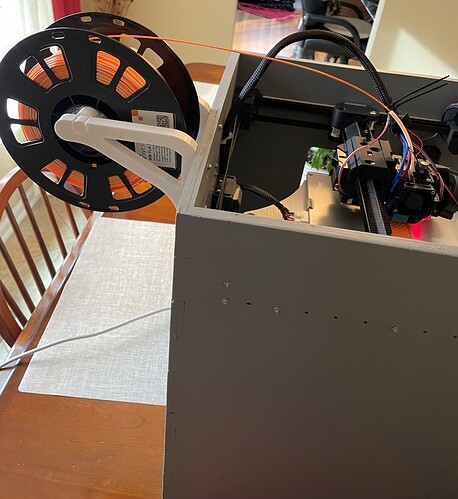

Also, I didn’t want to have the filament mounted to the side and have it travel up and then back down so I rigged up my own little spool mount for the back of the machine so that filament has a direct path to the extruder. Not sure if it was really necessary but I did it anyway.

Nice !

I am not sure what caused the odd lines on the vertical pillars on the boat cabin. Ill have to tune things up and print again to see if its a common error.

I already experienced similare with under extrusion when sometimes filament got “stucked”/doesn’t come nicely from the spool

Extend the filament “reverse bowden” tube all the way and mount it securely at the wall or spool holder. Tugging on the filament will cause decreasing accuracy, and some print inconsistencies. These are things I never noticed before, I think print quality is so much better now I am seeing all the small stuff.

I don’t think that is your issue here, I would actually bet your retract settings are off. Not far enough and it will drool (not seeing that here) too far and the filament heats up the Extrder too much. I set my retraction to 0.6mm I believe and at 30-40mm/s. Too fast and it will nto retract, too slow and it will drool.

Got it. Ill run the bowden tubing to the frame and secure it there. My only thought on this is that the tube obviously has to be long enough to reach the extruder when its farthest away, so then when the extruder is at its closest (right up next to the spool holder) then the bowden tube will be pretty bent with a large loop. Do you ever find that to be a problem?

Oh wow, my retraction distance was at 6.5mm at 25mm/s. Going from 6.5mm to 0.6mm seems like a pretty large change but ill give it a try!

That is right where the surface area goes down to a very small amount. It might be that the layers are not cooling enough to be solid for the next layer. You can increase the fan or increase the minimum layer time, or drop the print temp. Just a guess.

The retraction is a good guess too.

On a direct drive like you have your retract is very short compared with a Bowden setup where the extruder is far away from the hotend. So yes a retraction distance of 1mm or shorter should be all you need.

As you all can see, I have a pretty clear space between the bed and the bed plate where it is mounted. Are you all putting some sort of insulation sandwiched in this space or is it okay to leave exposed?

I use some insulation but I have never tested to see if it helps much.