Writing as i do: this turned out to be a long one

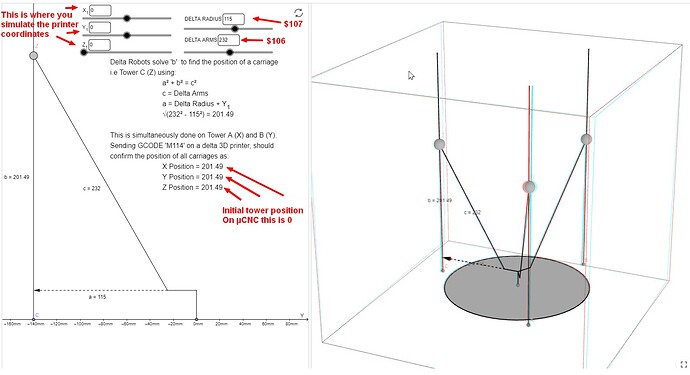

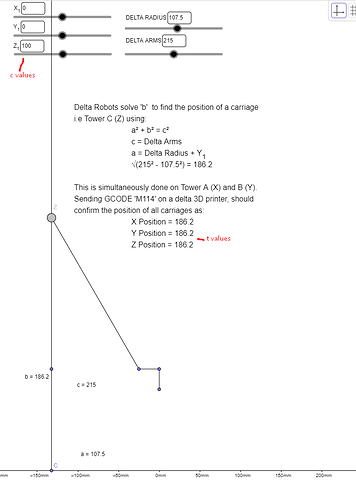

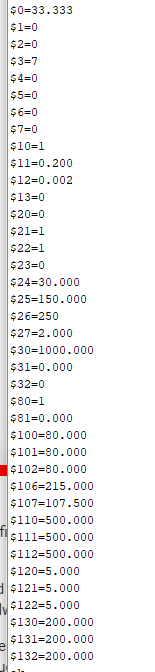

1- input the same 106 and 107 values on the printer and the sim: ok

2- Hini marked at 186.2 for each tower

3- moved the printer down with G0Z100 and positioned the sim at +100, the sim measures from the bottom where as the printer from the top atm. this might look weird in the calculations, not sure, ill see.

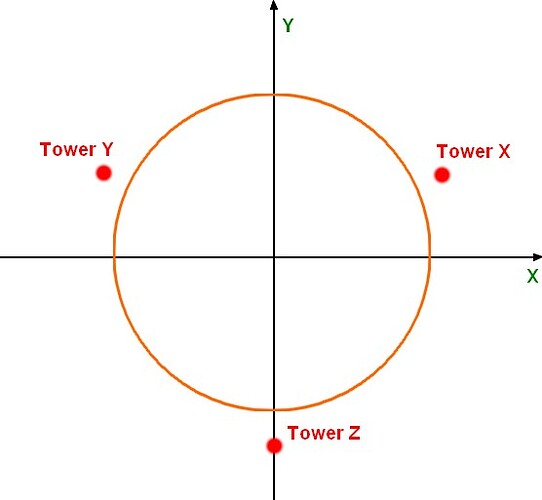

Xc Yc Zc - “cartesian coordinates” of the nozzle - what we input in Grbl

Xt Yt Zt - “towers coordinates” where the motors (more like the carriage of each tower) find themselves

this would be Xt Yt Zt, which if i move the effector down with a G0Z100 i know they are all 100mm.

i thought id have to measure with a ruler but “??” bring up an Ov:100,100,100 which seems to be the t position of each tower - i can measure both i guess, although it probably not necessary

the sim does not change the position of the tX tY tZ values regardless of where Zc is if Xc and Yc are 0.

i guess i can still measure the difference but should the Zc be the same as Zt? and not 100 vs 186.2

if its just something you didnt not add to geogebra no worries i was just wondering

up and down in the (brackets) refers to how to carriage of each tower moved from the previous point in relation to the ground

4- G0X40 sent through - seems like the effector lifted off the plane, anyways values are measured by hand because i cant bring up the Ov values with the ?? as i mentioned before

on the printer the values are: Xt: 115 (down by 15) Yt:74 (up by 26) Zt:96 (up by 4) - measured by hand

on the sim the values are: Xt:201.29 (up by 15.09) Yt: 160.07 (down by 26.13) Zt: 181.85 (down by 4.35)

the numbers are reverse either because there is a difference of the effector direction between printer and sim, G0X40 on my printer send the carriage in the inverse direction of the G0X40 in the sim.

.

btw i believe the current rotation of the overall steppers is almost inline with the stock configuration, X+ and X- face the correct way, but Y+ and Y- are opposed

a G0X-40 should create the opposing effect

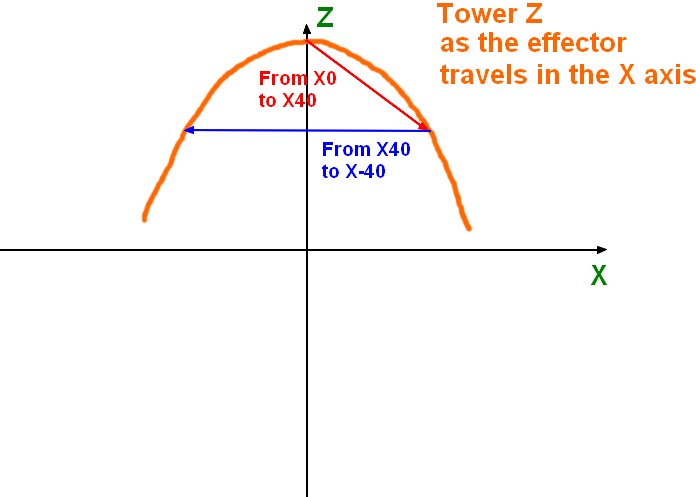

btw when going from G0X40 to G0X-40 the effector moves down and then up again - curved bottom as we said

Anyways in a G0X-40

on the printer the values are: Xt: 74 (up by 26) Yt:115 (down by 15) Zt:96 (up by 4) - measured by hand

on the sim the values are: Xt:160.07 (up by 15.09) Yt: 201.29(down by 26.13) Zt: 181.85 (down by 4.35)

in both cases printer Xt and sim Yt as well as printer Yt and sim Xt are inverted, its the Zt values that are in the wong direction.

If I input a G0X40 on the printer and a G0X-40 on the sim the Xt’s and Yt’s match, and in the inverted scenario too

I didnt catch this at first (bc the printer and sim values are inverted and it was confusing me but:

I saw it from the sim the Zt (compared to the ground surface) went down in both G0X40 and G0X-40, where as on my printer the Zt (compared to the ground surface) it went up (compared to the ground surface) this meant that there is about 4+4mm difference on the Z axis and I believe that mispositioning my effector -

1- ill measure my effector height from my desk/ground surface at G0Z100 (X0 and Y0) - call it “Eini”

2- then ill issue a G0X40 which as we know will move the effector upwards and the Zt 96 rather than 104 which the sim does, Xt and Yt should be correct - ill measure that too as “Eup” to confirm it did not move horizontally

3- ill tape the X and Y tower carriages so they dont move

4- ill switch off the power supply and move the Z carriage down 4+4mm to match the sim height of the Zt (dont know how to move only one tower in grbl)

5- ill measure the distance of the effector from the desk/ground surface once again as “Ex40”, if its the same as “Eini” we can assume the effector would have moved in a planar horizontal plane rather than the current spherical shape it does now if the Zt moved in the opposing direction

1- Eini= 138mm

2- Eup= 148mm

3- taped Xt and Yt

4- moved Zt down 8mm

5-Ex40= 146mm (not 138  )

)

seems like the 8mm on the Zt dont amount for the 10mm offset, in retrospect i dont know how i thought this would have given me those 10mm back given the delta kinematics…

lol

In the midst of this i sent the Zc up too high at some point and it the Y carriage hit its switch stopping the other axis very gracefully and without doing those awful stepper noises, so thats good!

Im trying the printer to sim comparison with a G0Y40 to see if its a Zt thing again or if it the discrepancy will manifest differently

G0Y-40 sent through - G0Y40 on the sim so they match based on effector position

on the printer the values are: Xt: 83.5 (up by 16.5) Yt:83.5 (up by 16.5) Zt:118 (down by 18) - measured by hand

on the sim the values are: Xt:193.31 (up by 7.11) Yt: 193.31 (up by 7.11) Zt: 156.42 (down by 29.8)

well i didnt expect these to be off in all direction…i was expecting to see an opposed value like before

-i was just about done here and ready to go to bed as i was confused, decided to run a G0Y-40 on both even though they effector goes in different directions

G0Y-40 sent through - G0Y-40 on the sim this time

on the printer the values are: Xt: 83.5 (up by 16.5) Yt:83.5 (up by 16.5) Zt:118 (down by 18) - measured by hand

on the sim the values are: Xt:169.61 (down by 16.59 down) Yt: 169.61 (down by 16.59 down) Zt: 204.13 (up by 17.93)

values match exactly considering i measured by hand on the printer, but they go in different directions, no skipped steps

as i mentioned before the Y+ and Y- are in opposing direction compared to the stock, i dont know if this is what could cause this but from what i understand its probably not

i guess its just the arm lengths and radii that are wrong, in that case ill revisit tomorrow for a quintuple check  aiai, sorry for the ridiculously long post

aiai, sorry for the ridiculously long post

![]() This was referenced by the reprap wiki but I guess it’s not reliable and the one from thinkyhead (Marlin) in not available anymore. I’ll try to figure out a solution…

This was referenced by the reprap wiki but I guess it’s not reliable and the one from thinkyhead (Marlin) in not available anymore. I’ll try to figure out a solution…