Hi there, just wanted to share my build progress and experience. I appologise if I double up or if I missed info from other posts. I am usually on here late at night to early morning.

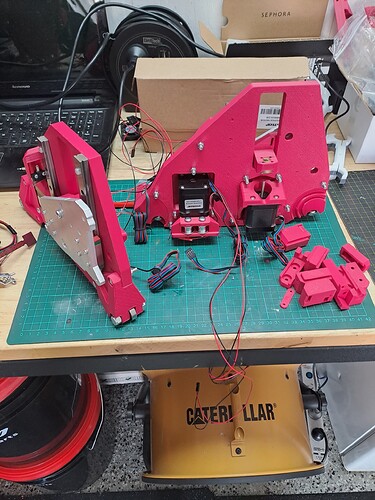

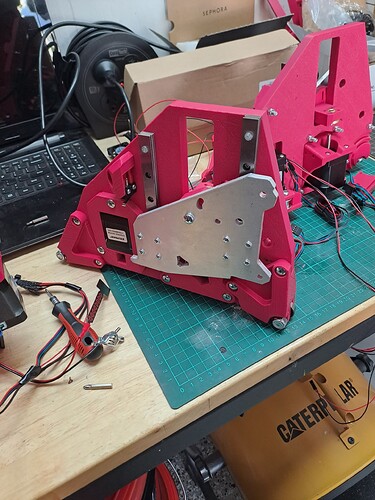

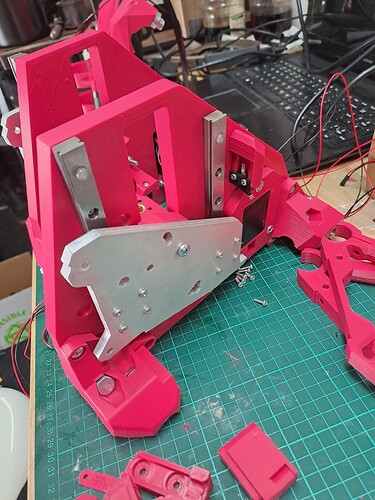

I have recently purchased the Lowrider CNC V3 hardware kit from V1 with the Metal XZ Plates, a couple of cutting tools and the Tiny Touch Plate ![]() , thank you @vicious1 . Was happily surprised with the time from placing the order on August 10 to it arriving August 28. I have help from a work mate who is currently printing the parts while I am busy trying to sort out a table for the LR3. Also have purchased 25mm aluminium tubing for the rails (3m from Bunnings, 2 of).

, thank you @vicious1 . Was happily surprised with the time from placing the order on August 10 to it arriving August 28. I have help from a work mate who is currently printing the parts while I am busy trying to sort out a table for the LR3. Also have purchased 25mm aluminium tubing for the rails (3m from Bunnings, 2 of).

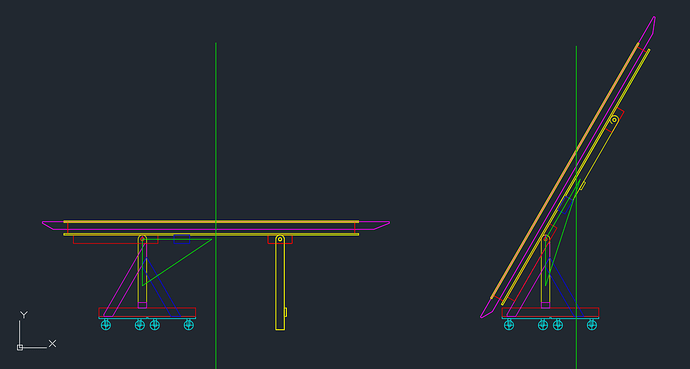

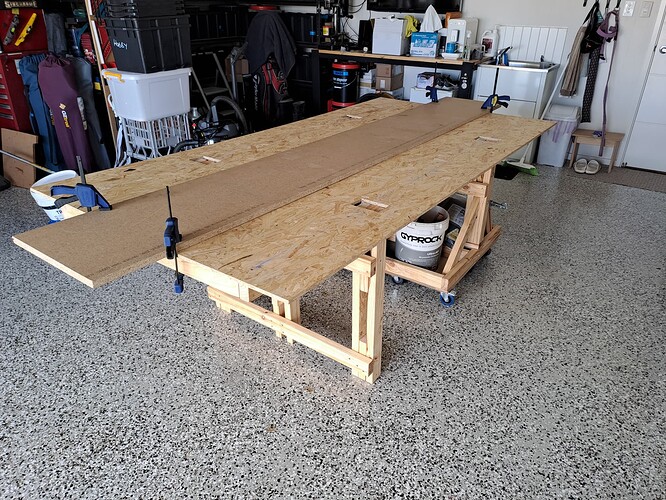

I have been keen to make a torsion box style table and with the help of @DougJoseph and his youtube videos and download files, I have the desired table design locked in. The next issue was room in the garage for the table, which will be able to accomodate a full size work sheet 2440mm x 1220mm , when not in use. I stubled accross a foldable design late one night but given the length of the table (Approx. 2900mm long) the height of the table would hit the 2700mm ceiling. So i decided on a 60° closed table that dropped flat with fold out legs at one end. Its a design that I will refine as I build it.

With the pivot point and centre of gravity of the table (Roughly 120kg + work piece and LR3) I will have 2 gas struts to assit lifting the table but more importanly assist with lowering. I will have over-centre fastners/catches to hold the table when it is stored at 60°. Found a great website to working out strut location, operation and calculator (both metric and Imperial) https://www.gasspringsshop.com/gas-spring-calculator/ if anyone is interested.

Will probably need some counterweight also. Cement bags will be standing by. I could not be bothered to round over the uprights, so I will just cut out provisions in the bottom skin of the table to accomodate the uprights.

I have used 25mm water pipe for the pivot pins (roughly 32mm OD) with 3 x ALDI Dolly Trolleys for the base. They wera a cheaper option than buying wheel casters from Bunnings or Mitre10 and I didn’t want to wait for anything else from overseas as all the other items for the LR3 have been delivered. I have installed two additional locking wheel casters on the corners of the edge where there is only 1 dolly trolley. I will also replace 2 corner ALDI casters with locking ones on the opposite edge.

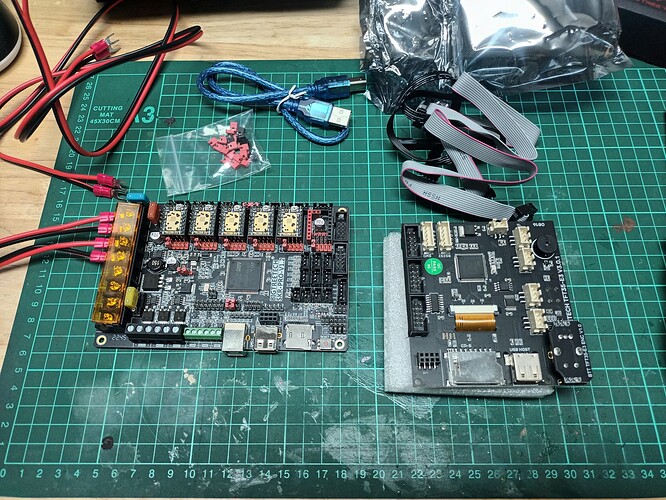

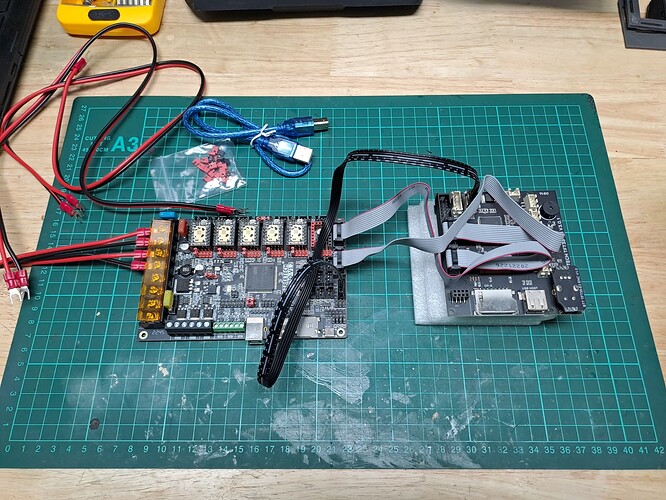

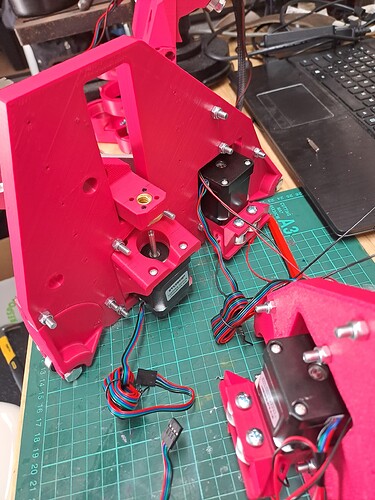

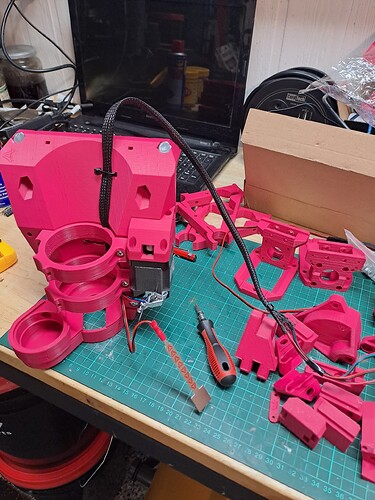

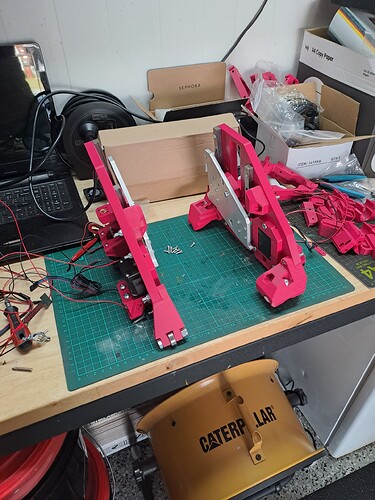

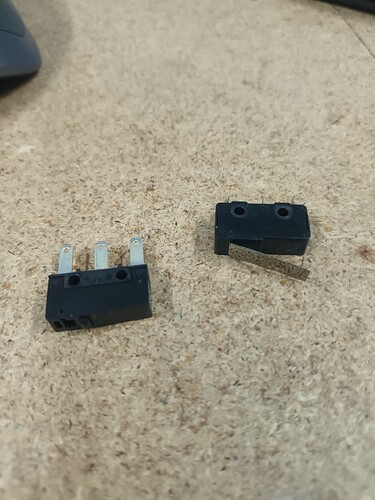

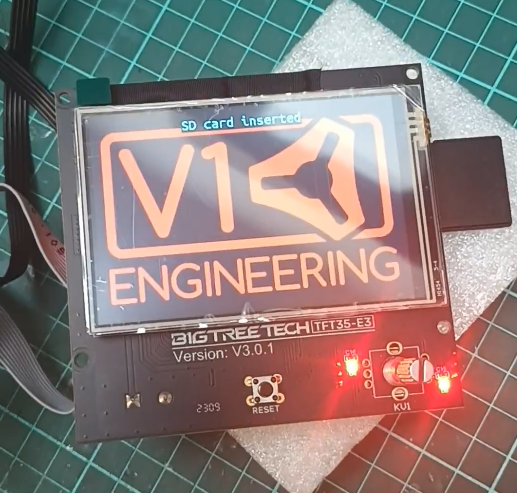

I have started working on the electronics. Those ducks though. Have preped the end stop switch wiring and have also purchased some insulated PET braid sleeving for when the wiring is run through the LR3. After bending the pin on each of the drivers they have been installed and removing the jumpers and placing one for the UART was done. I flashed the SKR PRO V1.2 before connecting the TFT35 E3 V3.0 and flashing it.

And thats where I am currently up to in the process. Plan is to have the sheets for the torsion table delivered next week and the printed parts should be close to being completed by the end of next week also. Need to source some vacuum hose and sort out the Bunnings Shop Vac and 3D printed DIY Dust seperator cyclone for a trail run. Other than that not much will be getting done this weekend being it is fathers day. I might start work on mounting the gas struts to the cross beam on the Dolly Trolly early next week.

Cheers, Sam ![]()

P.S. Any feedback will be greatly appreciated. TIA