Hi all - and no, I have not run away…

It is just that “life” has decided to make things “interesting” for me - and my ADSL provider… well, lets just leave it there.

I figured out that the aluminium j-bracket that the extruder mounts on is bent so I printed a new one - my first imperfect design on modern CAD.

The only problem is that the space between the 2 top bearing blocks I made bigger thinking that the further apart they were the better control there would be - but guess what!!! Now Alison has a usable width (left to right as viewed from above) which is significantly less that the 200mm she used to have - dhaaa!!! My bad. Not thinking things through properly…

I fixed up some temporary fans and ducting to cool the extruder tube (which work maybe a little bit too well - she battles to hold 180 degrees even when set to 200 degrees in the software) and the work-piece (possibly the same over-cooling issue!)

Now don’t laugh but this is what the “Christmas Tree” looks like right now.

[attachment file=58453]

The cooling “system”… A TOTAL MESS! But I was sitting without an internet connection so I had to make do with what I had - being a drawing for a cooler duct which I had downloaded just to see.

So I printed one - which melted on the bed - next print I used a hairdryer on a shoe-box next to the printer to give some cooling and although still a disaster, it was more or less usable - so I printed another one.

Mounted the fans to the ducts and hung them on the best I could just so that there was positive cooling going on.

This involved a lot of Dremel, odd bits of plastic, even a piece cut out of a soft drink can - but now the heater tube and the work-piece were getting cooling even though it looks like something the cat dragged in - it works!

MAYBE a bit too well!!!

The extruder simply would not get to 180 even when set to 205 - so for startup I put a piece of paper over the fans to “choke” them and give the element a fighting chance.

“Why not simply switch them off in the software?” I hear you ask…

Well, for some reason or other the fan control no longer operates so I had to wire them directly into the power supply.

OK. Now she was able to get the heater block up to 180 degrees and extrude plastic - well sort of anyway…

But while I had been sitting around with no Internet and fiddling around upside down on the extruder assembly (difficult!) I came up with an idea:

Seeing as I was going to have to re-make the whole extruder mount . bearing plate why no make it a “quick release” design?

So I designed a plate for the bearing to mount to (and made the shaft spacing a full metric size, not the weird “not metric / not imperial” dimension it is currently with a V-lip at the bottom and a placement stop on the left so that an “extruder mount plate” could fit in and be secured accurately.

All necessary wires would have to get plugs but I have some of them - even heavy duty ones for the heater.[attachment

Then I drew up the extruder mount plate as well.

Now to print them to see if everything worked together and fitted.

So the first “job” with the new cooling setup was these 2 parts - DISASTER!!!

[attachment file=58454]

The basic idea I feel is good but the quality of the print is terrible!!!

So I started changing the settings - and after 2 attempts decided to get a test model that was a lot lighter on filament and time.

Chose a hollow, open on 1 side, letter “W”. Only a few grams and it has enough surface area to write the settings and notes on - trying to keep track of things.

And by the way, I was now using a piece of glass as the print surface because the heated bed was bowing up to a millimeter depending on the temperature - at least she now has a stable, flat print area.

I sort of eventually figured out that there is now too much cooling going on.

This is the kind of artifact issues I am getting:

[attachment file=58455]

In my opinion definitely related to temperature in some way - either filament too low or part too cool.

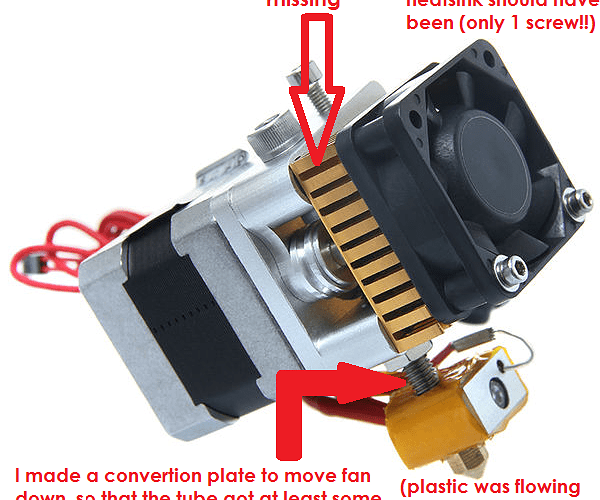

While waiting for these prints I did an updated extruder mount plate that incorporated a fan with duct to cook the extruder tube.

So just before I hit Alison with a hammer I decided to print my updated design - just to see…

[attachment file=58456]

This is the 2nd attempt - the first one was even worse!

I has downloaded a NEMA17 model from somewhere and I printed that so that I could see if the clearances were all OK and it is a good thing I did because it would not fit so I modified the design again and printed the one in the picture.

It came out pretty bad, better than the first one though and the motor now had enough clearance and there is enough place to mount almost any configuration of part cooling fan ducts.

That was at about 2am last night - totally disgusted I decided not to work on Alison today and guess what - woke up today and I had Internet again…

CHANGE OF DIRECTION:

So I went onto Youtube and got a message from a buddy about the Lowrider and so I went and had a good look at them - both here on V1 and on Youtube - pretty impressive!

Yes it can be built to handle a 1.2 x 2.4 meter sheet BUT I don’t need that sort of size.

1 meter x 800mm with a 150mm Z travel will be more than enough for me at this point so I am seriously considering the change.

And here is the other thing:

I will be needing to put on a rotary axis at some point so cutting a hole in the bed and mounting it there parallel to the X axis is an option that will allow me to machine pieces up to 300mm in diameter and maybe 800mm long - more than enough!

I’ll have to give it some serious though but like the fact that the longest axis is not a piece of tube but a solid table top - much less flex and harmonic vibrations for a start…

Oh - and by the way, how the hell do I turn off filament retraction on the Slic3r that is part of Repetier Host?

I have looked everywhere - know I turned it on at some point - now I cant find it and especially on the “W” the artifacting seems to be originating at the point where extrusion starts again after a long move and the associated filament retraction operation - seems like the first bit of extrusion fails/is dicey and that starts the process which then gets amplified and worse every layer.

Thanks for reading this people - what do you all think?

All the best,

Aubrey.