How can I setup macros so that I can use commonly used procedures. i.e. I have a very simple code for doing keyholes that could possibly be made as a macro.

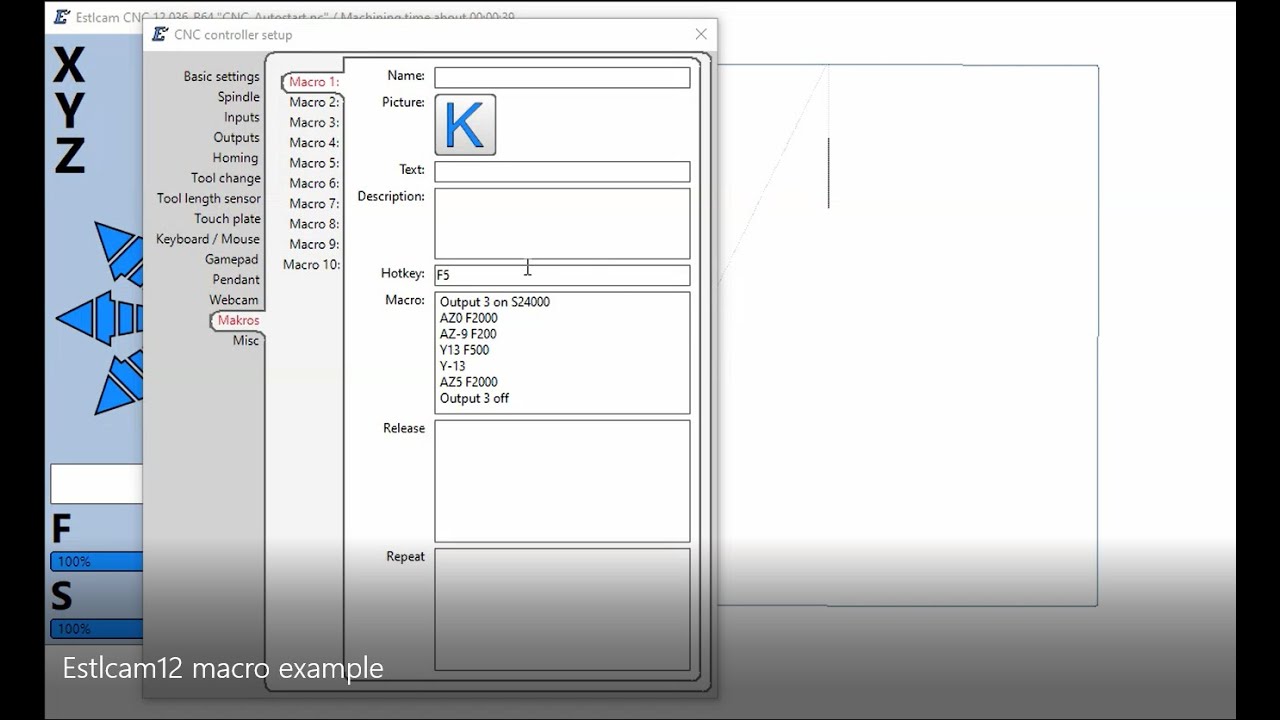

At least Estlcam 12 has got a dedicated Macro tab (see below):

Thinking about it, those might only work if you are using Estlcam as a controller as well.

Yes I found that section and have written a macro to test out, but not sure about some parts of that screen. What is Release used for and also Repeat.

The macro part is pretty simple

G21

G90

G94

M03 S24000

G00 Z5.0000

(No. 1 Engraving machining: keyhole)

G00 X0.0008 Y0.0119 Z5.0000

G00 Z0.5000

G01 Z0.0000 F200 S24000

G01 Z-9.0000

G01 Y12.9619 F500

G01 Y0.0119

G00 Z5.0000

G00 X0.0000 Y0.0000

M05

Maybe I need to add some more code to start and stop, but not sure how to do that.

No idea, haven’t tried it yet. From what I’ve just googled you can only use it if you use Estlcam as the controller as well.

I have set it up to test when I get time, but one problem I found was in making the button graphic. I used Corel Draw to make the image and saved it as SVG, but it doesn’t look quite right although it works okay.

Maybe there is some info on the best ways to do button graphics for Estlcam, but I haven’t been able to find any yet.

Estlcam controller macro, see command-line help pane for options (Spindle on/off = number of board Outputs +1).

Output 3 on S24000 (start spindle @ 24k)

AZ-9 F200 (Absolute to Z -9 @ 200)

Y13 F500 (Y back 13 from current position @ 500)

Y-13 (Y forward 13 from current position)

AZ5 (Absolute Z up to clearance plane)

Output 3 off (stop spindle)

G-code (untested, not for the Estlcam controller which doesn’t need/use G21, 90, 94, or 91)

G21 (mm)

G90 (absolute coordinates)

G94 (mm/min)

M03 S24000 (start spindle @ 24k)

G01 Z-9 F200 (Z down to -9 @ 200)

G91 (incremental coordinates)

G01 Y13 F500 (Y back 13 from current position @ 500)

G01 Y-13 (Y forward 13 from current position)

G90 (back to absolute coordinates)

G00 Z5 (Z up to clearance plane)

M05 (stop spindle)

I tried that out Dave and after some fiddling around I found that this code works okay

G21 (mm)

G90 (absolute coordinates)

G94 (mm/min)

M03 S24000 (start spindle @ 24k)

G01 Z-9 F200 (Z down to -9 @ 200)

G91 (incremental coordinates)

G01 Y13 F500 (Y back 13 from current position @ 500)

G01 Y-13 (Y forward 13 from current position)

G01 Z14 (Z up to clearance plane 5mm)

G90 (back to absolute coordinates)

M05 (stop spindle)

Tomorrow I will test it on the machine instead of simulation.

I chopped it down to this and it still works okay

M03 S24000 (start spindle @ 24k)

G01 Z-9 F200 (Z down to -9 @ 200)

G01 Y13 F500 (Y back 13 from current position @ 500)

G01 Y-13 (Y forward 13 from current position)

G01 Z14 (Z up to clearance plane)

M05 (stop spindle)

What controller firmware and G-code simulator are you using? I don’t know how you plan to use the macro, but your last G-code only works when the Y coordinate is zero. Using incremental coordinates for the Y move allows the macro to be run from any Y coordinate. The only way to do that (and start/stop the spindle) using the Estlcam firmware is with the maco I provided.

…Note: I’m not recommending cutting keyholes that way, I straight tool a keyhole shape and then use the keyhole bit (saved as a project file that I Insert/Add to projects that need them)… That AZ5 looks like its faster than 500 and needs needs an F.

The way I have been using it is by marking where the keyhole needs to be with a pencil, moving the tool to that position, zero everything and then start the code. It has been working flawlessly using code, so as I use it a lot I thought to make a macro instead of having to load the code each time I need it.

I haven’t tried in real-time yet of any as macros but will do so tonight.

Okay, I just finished testing on the machine, using Dave’s macro and it works 100%.

Thanks for that Dave.