In the beginning…

Build is in Brisbane Australia.

I’ll be building a 3000x1550 bench for it to go on. This will be a full sheet machine.

Will build stock LR4 first and get a baseline for the performance of the machine, then make a few changes to get obstructions off the bench surface to make the bench more usable as I have plans to make the bench multipurpose. But I need a baseline to know what I am losing in performance as I make those changes.

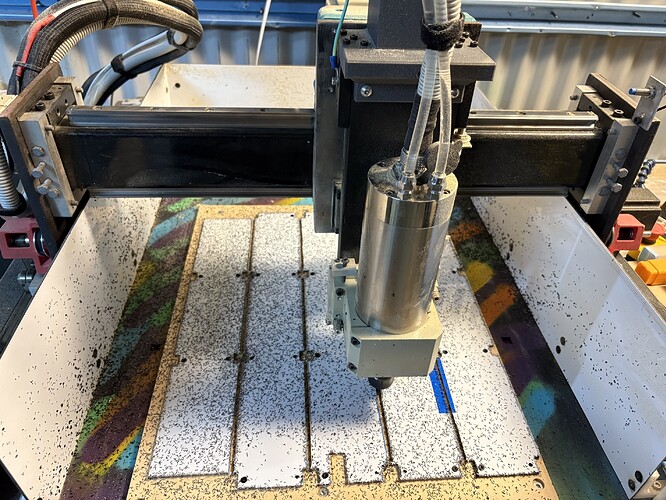

I finished my other CNC recently and was able to cut my plates out of 10mm aluminium plate. they turned out really well.

The other CNC can cut steel and aluminium with a build area of around 450x650.

-

Primary goal for this machine is to be able to cut contours in sheet stock - ply and acrylic/polycarbonate.

-

Stretch goal is large slab surfacing(may require some more modifications to get some more Z - we will see)

-

Stretch stretch goal would be to do contour cuts to process larger bits of aluminium plate - say 5 or 6mm 5083 and cut down to size to fit on the smaller metal cutting CNC.

I’ll be using a genmitsu router to start with, with the intent of upgrading to a 1.5kw VFD driven spindle down the track. I do not necessarily think I need the extra power - I have rapidchange style toolchanger on the other CNC and would like the same on this. The requires being able to reverse the spindle and have relatively fine control at slow speeds - not something I can do with the genmitsu router, makita or other clones.

Still undecided on controller. I originally purchased a 6x for this, but its in the other CNC and going great.

I have an SKR 1.3 I could use, along with a spider and some other boards. I could use those with GRBLHal however I am really liking fluidnc. I would buy a 6 pack but the only ones available on elecrow are external driver ones. May end up ordering a jackpot. We shall see…

Oh and I have a PicoBOB DLX + BOB that I can use for LCNC or GRBLHal on here until I get a fluidnc board to use. Either would work just fine, though LCNC may be excess to requirements for a lowrider…

I think this would be a better move than the SKR or Spider in the first instance.

Greetings from the Sunny Coast! I love the colour as the pic shows it - is it some sort of Vanilla Off White?

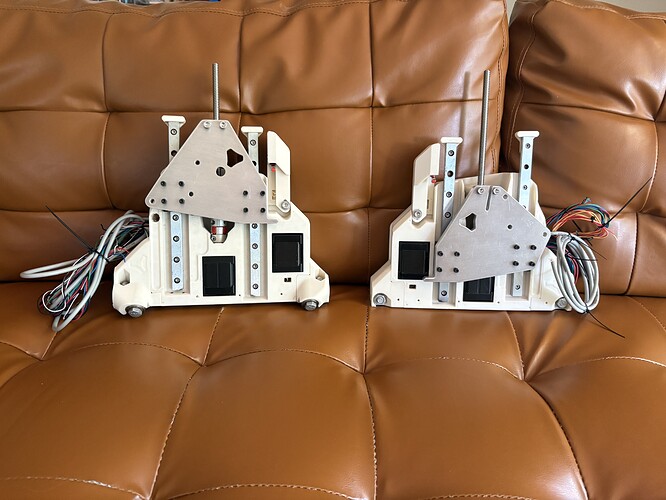

Hey Peter. Great another Queenslander! It’s Overture Natural ASA ![]()

Natural ASA is pretty much my favourite filament. I know ASA is not recommended for lowrider - but I’m happy to take a chance here…

It’s got kind of a bone finish.

My experience with this specific filament is it’s very stiff and strong. Great for 3d printer parts, functional parts around the workshop etc.

Plus it’s what had on hand.

I think that is all parts printed. Temporary strut plates cut.not a lot to do before I can start building!

You should add a touch of caramel. ![]()

The build continues ![]()

it is the caramel backdrop in the photo. Nice!

I think that’s the first larger LowRider 4 I have seen so far. Interesting. ![]()

Rail length is 1500, gives me a cutting area of 1334 on x. I will be putting a VFD spindle on here long term, as I have cloned rapidchange ATC(not for sharing, I don’t want to take away from the creators by doing that). This gives me space at the side to fit the rapidchange and a full sheet.

It probably looks bigger than it is however, as I have added extra strut braces. As beam stiffness is proportional to the cube of length, and a lot of the stiffness in this design comes from the strut plates and braces, I figured extra may help compensate for the loss in stiffness from the extra length. Long term I would like to cut or reinforce the strut plates with 5mm aluminium sheet. Also I could only source 1.2mm thick tubes so every bit of extra support helps

Quite keen to see how it performs at this size ![]()

Oh and I extended z 50mm. Mainly because those were the parts the parts bin provided and modding the endstop position was easy - and in this design there is no mechanical disadvantage to having extra z - it’s only a disadvantage to cut with extra z

Looking good!

that color, looks soooooo good