The LR4 is a great machine. It has solid rigidity and great functionality, and at a price point that can’t be beat.

I first built LowRider v2, then upgraded to v3, then upgraded to v4. The added rigidity of the v4 means you can increase speeds and feeds and get done faster. Of course no machine can take away bit deflection (bending of the bit under pressure), and as always, properly adjusted feeds and speeds are the key to getting good performance.

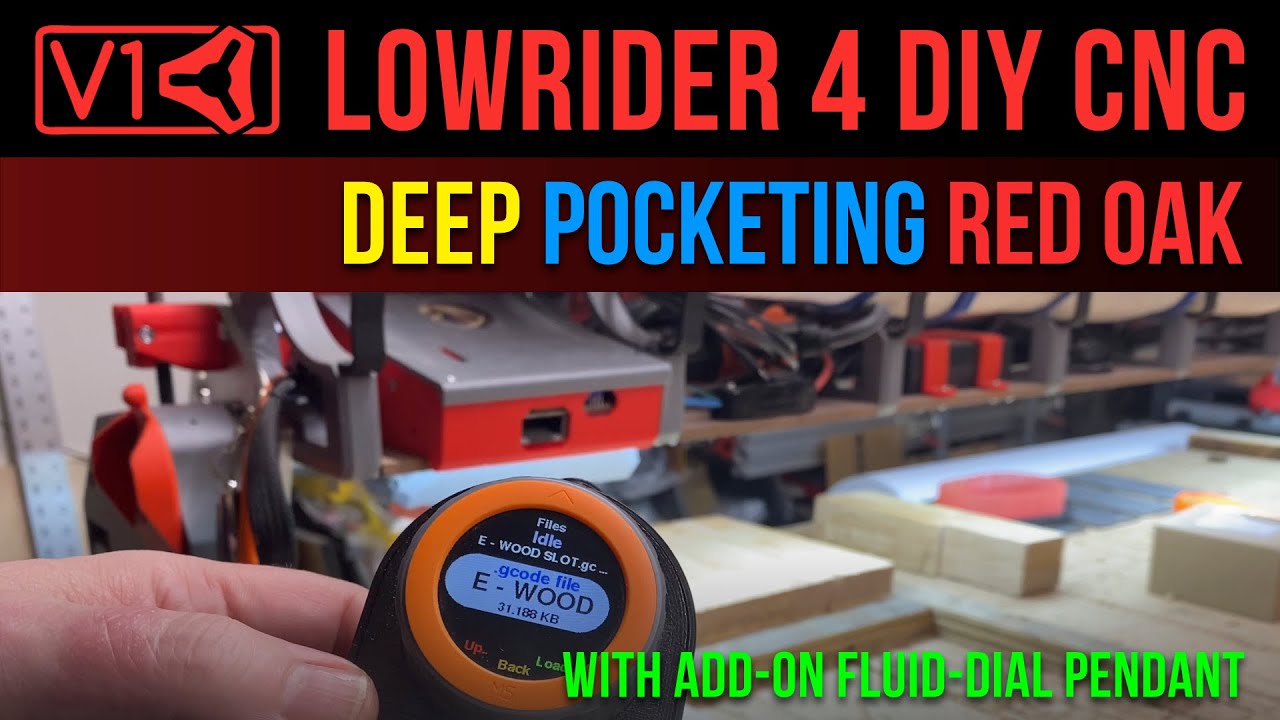

As for how long I’ve been cutting with LR4 — I was in on it early with the beta test group. I’ve done quite a few projects with it, several of which were documented either here or on YouTube.

See these:

And see loads of other stuff here:

https://forum.v1e.com/tag/gallery-lowrider-cnc

When it comes to breaking bits, if your speeds and feeds are right, you will usually just see a bit get dull over several jobs, and eventually need replaced for good sharpness.

Build stock first, and definitely do get a router with speed control, and get some way of calculating speeds and feeds for jobs — and you’ll likely be so happy you won’t consider trying to soup it up. It’s a concert package. Everything is well matched for everything else, with a view to getting good performance at a great price. As soon as you try to spice up one part of it, you create an imbalance because you did not soup up everything. I would dare say anyone thinking the NEMA17s are not powerful enough is probably either not doing speeds and feeds right, or trying to force a dull bit to keep working.

Re. comparison to a OneFinity — my LR4 has double the cutting area of the largest machines from OneFinity, and at about 1/4 of the price. The speeds I’m getting are fast enough that I don’t have any sense of needing a faster machine.

Re. spoil board: I just use MDF, and for material hold-down, I screw things directly to the MDF. Works great, would not have it any other way.

Re. how to keep clean: dust collection works surprisingly well, and I really have no issues regarding keeping chips out of the mechanism. After each major cut job, I have a very minor bit of vacuuming a few tiny chips up from the spoil board in the area around where the material was. Very minor.

Re. too slow to be used with a fixed-speed router: As I have done more and more cutting, and more of faster speeds and speeds testing the waters on the LR4, I’ve gotten to where I often run jobs with the router speed knob set on #4 if I’m using a 1/8 bit — which is pretty fast. It also all depends on the material being cut, how many flutes, how sharp the bit is, how deep the depth of cut is, etc.