Either way, that is not your issue. We need consistency, tram will be consistent.

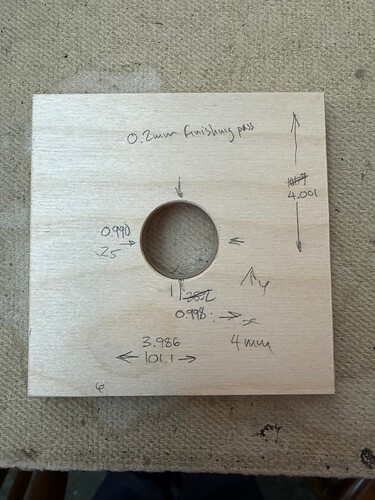

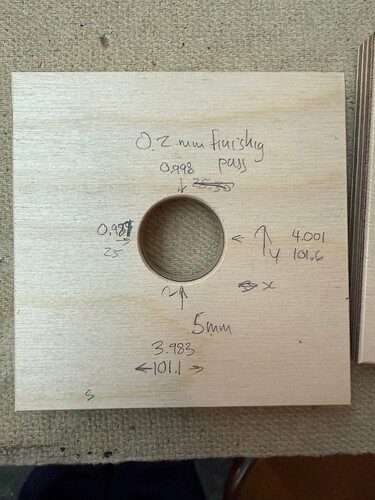

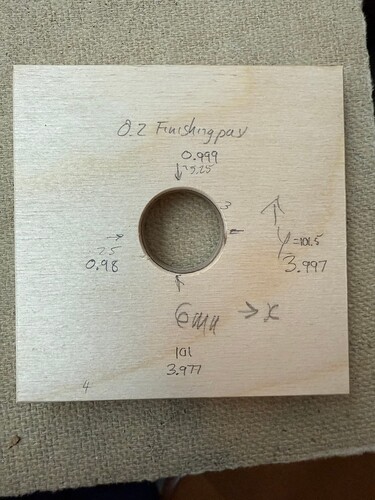

Alright, I may be more confused than before. The only changes I made to the machine last night were to level the Z pulloff from homing (pretty sure this is unrelated but still needed to be done) and changed the bit to a new 1/8 2 flute as I wait for single flutes to arrive. I cut 3 4”x4” squares with a 1” circle in the middle. The square was cut using a simple slot cut from ESTLcam at 4mm, 5mm, and 6mm DOC respectively. The circle hole in the middle was cut using the same DOC, but with a linear pocketing. I got the hold down tabs correct this time so each square and hole had a 0.2mm full depth finishing pass as well. Material is 12mm Baltic Birch. Feed speed was 500mm/min and Router RPM was lowest setting on the RT0701c which is ~10000rpm. I forgot to download the Gcode but will try to get that attached and uploaded later today when I get home. I have attached pictures of the pieces for reference

The order of operations was the 4mm doc hole was cut first, then the 5mm hole, then the 6mm hole, then the 6mm square, then the 5mm square, and finally the 4mm square.

Generally the cut sounded fine, there was some grinding that could have been missed steps on the cuts for the 5mm square but the dimensions came out fine so I don’t think it was an issue.

From these pieces it looks to me like I am within 0.003” (I am ridiculously happy with that) in the Y direction and 0.025” (less happy with that, but as Ryan has said, consistency is key here) in the X. These were consistent across all three pieces.

I guess in hindsight it makes sense that a dull bit would cause heavy deflection as the machine has to push it harder through the material - I just didn’t expect the bit to be worn out so quickly. It had maybe 5-6 hrs of cutting time on it, most of which was 12mm DOC trochoidal and 0.3mm full depth finishing pass. Perhaps I ruin it with my 1mm doc testing and have been chasing a ghost since then? What kind of life should I expect from a carbide tool, and is there some indication its going out other than pieces are dimensionally non functional?

10% bit diameter or more in soft material. I think you need 0.3-0.4mm.

I know this is silly but we all have to convert this to 8.3mm/s. The thought here is; it is far easy to visualize 8.3mm and one second than it is to do 500mm and one minute, especially if your part is smaller than 500mm.

Pedantic, maybe, but mm/s helps us help you faster.

8.3 is a good place to start for a single flute, but you need to feed a two flute, twice as much material. More flutes = faster and shallower.

Since you are using a two flute endmill in soft material you can not go any deeper or the endmill can not evacuate the chips. The reason is the flutes are tiny and the chips from wood are large.

Okay with much more ideal cutting conditions 5-6 hours is normal, but I would think 10 hours is pretty high. It varies greatly with each tool you use and what you expect out of it. You will be able to hear the difference eventually. A fresh endmill is quieter and leaves a better surface finish. As it starts to wear it gets louder and the edges are a bit more “torn” not cut.

If your cut recipe is good you leave a little on the table so if you are not on the raged edge of machine load, so as the end mill wears the load increased.

The “proper” way to do this is a roughing endmill, and a fresh one to do the finishing pass. If you want the ultimate in accuracy that any CNC can provide that is what you do. Most of us do not care enough to do that tool change to get that sort of accuracy.

- Don’t forget for a finishing pass you can also move faster or slower. If you want to chase those zeros this is another factor. I typically move at about the same speed as the roughing in wood.

Showing us a closeup of the edge of your cuts can help if you have more questions.

I assume at that speed with the two flute you actually have a bit of charring, or the beginning signs of it. (really killing that endmill just rubbing it on the edge).

Chips carry away heat, the is too fast and too slow in CNC. Kinda sucks you can’t just go as slow as you want. This is extremely noticeable in metal. Your endmill will weld itself to the material in moments if the heat is not getting pulled away, or snap if you move to fast.

We’ve had this discussion multiple times, there are also people who work better with mm/min. ![]()

Oh and it is a bummer but you can dull and end mill in moments so 5-6 hours is not the low end, seconds are.

One day you will probably cut through a screw, you will hear the difference between a good and bad endmill right then, and you will be excited that the CNC cut right through steel.

I know but the yellow brick road has everything listed in mm/s. If I have to divide everything by 60 I tend to wait and see if someone else will help instead. So if you want my help I prefer mm/s.

All my milling basics recommendations and setup is done in mm/s so that is how I have it memorized.

Makes sense. ![]()

I am using this thread to take notes for a “milling advanced”, or a “chasing zeros” page, along with some more comprehensive settings for each end mill and material.

I know we are lacking in that department but it was for a good reason. I think we are in a good enough place now with each new build we have an actual “normal” range for these settings.

Ryan - Just making sure I have everything correct here:

It is entirely possible that an end mill went out after 5-6 hrs of use, and that very well could have been the source of my problems.

I have no preference for mm/min vs mm/s other than in my jackpot controller, gcodes, and fusion its set in mm/min so that my only reference.

If I understand it correctly what you are saying is 6mm DOC is really the deepest I can go on a 2 flute, purely due to the inability to get wood chips out. Wood chips mean heat is leaving and thats ultimately what we want out. Heat = enemy and destroyer of bits.

In other words a single flute should be able to do 6mm DOC at 8.3mm/s, and the equivalent wear on a double flute would be 3mm DOC at 16.6mm/s? Or would it be better to go even deeper and faster with both? I.e. single flute is 9-10mm DOC at 16mm/s and double would be ~5mm DOC at 30+ mm/s? This is with a 1/8 endmill. How would these numbers change with a 1/4, or is that still something that needs more testing and knowledge before there’s a definitive answer?

I knew going into this that the v4 was new and likely didn’t have all this info and I’m happy to have been some kind of guinea pig for it, but to your point earlier, I waited altogether too long to ask for help. I very much appreciate the assistance. Makes me feel kinda dumb that its seems to be just a bit issue but I digress.

I don’t remember seeing any burning on the edges, but will check again when I get home today.

Just for my own curiosity and clarification as well, and perhaps others if they get confused as easily as me - in the milling basics page the DOC start point is at 1mm DOC. I recognize this is in foam, but if 1mm DOC is as bit eating as its made to sound, where do we go from there? I supposed the idea is to get a better DOC in foam before moving to wood as foam will generate very little load, so perhaps I interpreted entirely incorrectly. I read that as if 1mm DOC works in foam at these speeds then they will work in wood. But that may eat a bit in one operation? I’m guessing based on context of this discussion that that 1mm DOC is specified in foam just to make sure the machine is moving correctly then increase the DOC and speeds methodically till you reach at least 1 diameter DOC in foam before moving to wood. That is decidedly NOT how I did it…

Could be after 30 minutes if it heats up too much. ![]()

I presume a bigger bit handles heat better, and thus potentially lasts longer.

But there is the tradeoff of physically being able to move the bit through the material. Obviously running a 1” endmill 1” deep would remove a load of material and handle heat better than a 1/16” but you have to have some power to move said cutter.

It is not a big deal but another way to think of it is 8.3mm/s is a bit slow, 15mm/s might be a bit fast. 500mm/min is a bit slow, 515mm/min is still a bit slow. I think a better scale for the speeds we typically use is mm/s, if it does not matter to you yet, I suggest mm/s so you can be inline with how the docs are formatted and I think it makes it more intuitive for making on the fly CAM changes.

When cutting MDF I have hit several rocks. When in doubt, change the endmill first. Now you know, not a big deal. Your endmills are not wasted though, you can still use the dull ones for roughing if you wish.

Yes. Heat, but you are also means you are recutting chips and wasting power, packing chips into your slot and dramatically increasing the load. If you are pocketing, you can go full depth, slotting is it’s own monster.

It is not about wear. When you have the right chip load wear is very little. It is about chip size. To get the same chip size on equivalent bits (flute angle), twice the cutting surfaces = twice the feedrate.

Remeber we are talking about slotting. Pocketing is much easier and forgiving. You want to go as deep as you can while getting nearly complete chip removal. Deeper is better for tool life, recutting chips is worse for tool life.

For some this is counter intuitive. Larger endmills have the cutting edge moving (swinging) faster at the same RPM of a 1/8” So you need to move a 1/4” faster. 1/4” also has a giant chip evacuation flute so you can take bigger bites and still get them out of the hole, and is much more suited for fast cutting in wood. The material removal rate should be a little better for the same tool load. (and a 1/4” is more rigid….but not sure how often we get into the rigidity limits in wood for our CNC) You can look at my old cnc race video, I take a suggested ~2+minute cut down to like 40 seconds with a 1/4” single flute.

Shoot, CNC operator is a career that takes a lifetime to master. You built, wired, created a design, did the CAM, and ran the machine….mistakes will always be made, every cut can be done a million different ways. You are doing great…but yes ask sooner!

My advice is find a recipe that works for your machine and just stick with it. I stopped trying to cut things as fast as possible, I just want to cut things once and know they will be as I expect. Now I only do speed tests to see if my new machine is better than my old one!

Burning where is slows down for a corner, more ripped than cut. It can be very fun to do a simple test cut with your old endmill and then with the new one and look at the difference. Then down the road when you have 20 endmills you can recognize a dull bit instead of trying to keep track of cut time on each one like the pros do.

Some people have a hard time with the building aspect and can not immediately go to 4mm DOC. The basics page is just that, basic, first time ever operating a CNC. We need to see if a machine can handle 1mm before you go more. test cut test cut test cut. 1mm is not a bit killer, unless your setting are really bad. If your setting are that bad you would have killed it at 4mm DOC as well, it would have just taken 4 minutes instead of 1 minute.

It is not just heat, but if you ever see heat marks on your endmill, it is 100% dead.

Just an FYI for MillMage. The new version has mm/min and in/min. They removed mm/s for some reason. I haven’t seen an official reason for it yet on the forum.

Yea, there is a topic on their forum about this.

Awww man. It’s fine either way but it is a personal preference, I can not imagine how having an option takes much more than a few lines of code. Even at superfast speeds, to me smaller units make sense, but so do large. We have been over this a lot of times but for me I have a decent handle on mm to inch conversions, above that I think in feet, below that mm. I understand that is probably very unique to me.

1000mm/min = ~17mm/s

2000mm/min = ~33mm/s

+1 Not just you

Another +1 on that.

Yes, but the outcome of the latest discussion where someone offered to write a plugin to have hover-bubbles with unit conversions, was that you (and 49% of others) were just thinking wrong. ![]()

The plugin sure would be nice.