So impressive!!

Your work is exceptional! I love seeing what you accomplish! So that is what i would call exotic woods, and in the u.s. fairly expensive, is that also the case for you?

It really depends. For instance Purple Heart is as expensive as Black Walnut because Africa is closer to me than America… I wrote something about my last haul here:

Red Heart and Satinwood are on top of the whole shebang in the picture with the trunk (the last picture).

And @vicious1, can we have longer bristles, pretty please? My 6mm endmill sticks out 20mm and the bristles cover the collet and barely anything else. There is nearly no sucking happening, you’ll see it in the video one it’s up. I know they bend when they are longer, that’s not a problem as long as they don’t get caught. ![]()

Did you print your own? Just do 120% on that axis!

How much longer do you want them?

Make sure your collet is up as high as you can, 2mm under the core is perfect.

It is. I think I need at least 35mm, rather 40. I can be the guinea pig that tries whether that’s working.

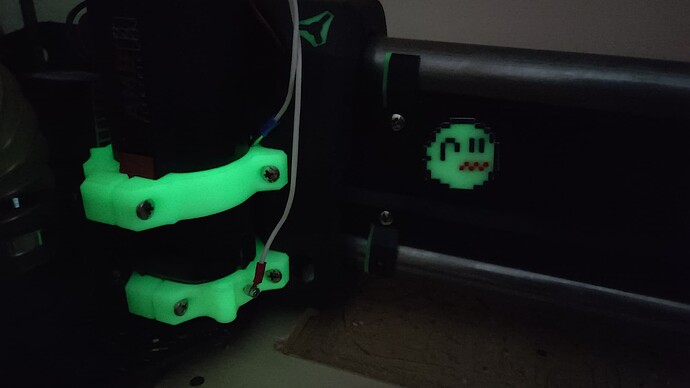

But I just remembered that I can slide the shoe down maybe. Let me check that first. ![]()

The current one is 22 if I remember right.

1- When making a new one here is some general math. To get us close. we need the gap from the top of the material to the edge of the dust skirt part. You want to make sure you factor in the depth of the first cut, and then 3-6mm of a gap above that.

So your bristles should not touch the material on your first pass just be close.

2- At full depth the bristles should not be able to touch your end mill, for obvious reasons.

If I need to make a picture let me know. Maybe I have not had enough coffee to get the right words out.

I can just make a long one and let them be cut to fit but that little triangle stiffening feature is really nice for controlling curl, without making it too stiff.

Nah, I know what you mean, I made bristles for the LR3 after all. ![]()

I was able to lower the dust shoe by 5mm, so I’d need ~32mm bristles I guess. Pretty please. ![]()

Sorry had to help a friends’ Mom with a busted toilet.

TPU Bristles 32mm.zip (291.7 KB)

Can you give that a try and let me know. I can add it to printables if it works out and doesn’t just suck under. If It does I can modify it a bit.

hahahaha, I thought that resembles a broken toilet ![]()

![]()

Printing it now. Can hopefully test it later because tomorrow I am leaving on a class trip. ![]()

/edit: Print is done, I also printed another lower part so I can just swap them depending on the endmill. What I can already say: They can’t be longer than 32mm. If I bend them inside, they roughly leave 5mm of space around them (they are not going to bend that far on the CNC, but any longer and they might).

/edit: Perfect length, does not get sucked in neither by the router nor the vacuum, though I did not test it when it goes below 0. The dust shoe on the LR3 sucked it in all the time.

That’s when it runs at 24 000 RPM and the vacuum. Slight bend, that’s about it.

Cool!

I am in the process of building a small grain mill for my wife to take with us on holidays. I am using the coffe grinder of my broken down coffee machine.

Prototypes in PLA:

MK4S overhangs anybody? ![]() Needs a bit of tuning though

Needs a bit of tuning though

Wooden version:

I am pretty excited about it. ![]()

Reuse/re-purposing. Love it.

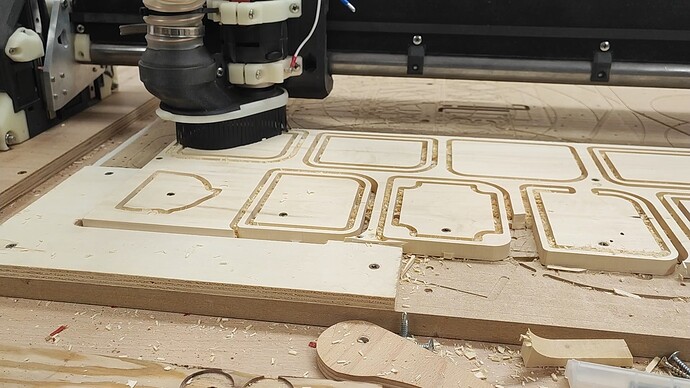

Cutting those 5mm, flimsy wood things at 3000mm/min and 4.5mm DOC with a 6mm 2-flute endmill. Would have taken me 4x as long with a 3.175… ![]()

man, i am not sure what is more impressive, your work, or your wife takes a grain mill with her on Holiday!!!

Not yet, but soon. ![]() Our kids nearly only get bread that she baked herself. Poor kids.

Our kids nearly only get bread that she baked herself. Poor kids. ![]()

![]()

That looks awesome!!!