First project with the new LR3.

Nice! I’m getting ready to start a Les Paul for my son. If you have any workflow tips you wouldn’t mind sharing, I’d love to hear them.

Oh you tease, is that all you’re gonna show us?

At first glance I thought you’d done a glue up then I looked closer at the grain.

Sure. Watch everything you can find on YouTube (I don’t mean watch all of YouTube, just the good stuff). Two Cherries Instruments is a great place to start. Also Highline Guitars.

I need to do a walk through of my approach. You absolutely need to become proficient in a tool like Fusion 360. Both in the CAD and in the CAM side - almost equal amounts of work in both.

Yep. Sounds like we’ve been headed down the same path. I’ve been watching both of those channels, and I’m getting there with Fusion 360. I made a LP by hand for him three or four years ago, so I’m interested to see how the CNC changes things - for better or worse. I’ll be doing some test cuts in foam this weekend, and watching your progress!

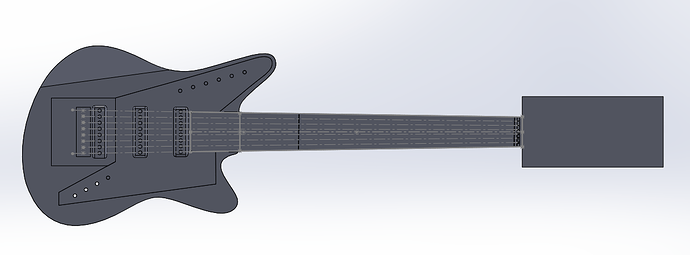

Oh man, awesome! I want to CNC a guitar design I made up a few years (I think?) ago and just found.

I think it’s a Vox Invader/Fender Jaguar cross - if I end up milling it I’ll try match the Invader tilted neck pickup and fretboard. I also wanted the bridge pickup as close as possible to the bridge for as much twang as possible…

I’m not sure where I was going with the pickups, I have a hunch that it’s some weird brain fart from wanting it to be a 9 string like the 9 String Vox Teardrop, and then I wanted each polepiece to have individual volume control, so each polepiece was an individual coil.

I wound some pickups even longer ago, matched to my old 1960s vox phantom, very few winds and very loosely wound, they worked out great - they screamed and were almost untameable.

The excess of controls was for inbuilt distortion/treble-booster/repeater and e-tuner/tone/drone

This is so cool? Do you have the Fusion File, by Chance? I’d love to do a guitar as well, but need some pointers on how to draw it. Also, depths and stuff for the electronics.

Sure, I’ve put the file on a google drive here: https://drive.google.com/file/d/1dpK8njr6CawH1c_xbRYrGQaejnAONrBD/view?usp=sharing

I didn’t do anything to clean it. There are remnants of a patch I routed out to recover from a router bit failure. The overall dimensions came from drawings from here, Fender Telecaster Guitar Templates | Electric Herald

I just recorded and uploaded an unedited walk-through of the model. I’m a software engineer explaining mechanical design, so your mileage may vary. Telecaster Design Walk Through - YouTube

Thanks so much, going to have a look tomorrow.

John it’s beautiful! I did several Telecasters on a home made CNC router about 10 years ago. I used a design by Chris Cockran and I believe the files are still available to download if anyone is interested. Chris Cockrum's Guitar Building, DIY, CNC, Electronics, Shooting, Reloading, and Mathematics Page The files are listed at the bottom.

BTW, I just started the process of printing the parts for the LR3 and ordering the electronics from V1Engineering and you can bet I’ll be making some more guitars in short order!

What is the process of making a guitar neck like?

Would it be possible to perform it with a LR3?

I imagine the neck radius would be tricky/time consuming…

If you have a 3D model it’s just the click of a button.

I was under the impression 2.5D Milling took a long time… I’m very tempted to give it a try

I have too many projects in the pipeline though!

Edit: Woah! Repetier Host is telling me it’s about 1.5 hours…I’m surprised that it isn’t much longer!

My experience is there is a whole lot of cursing before during and after too.

With luck, the after is “Hell, yeah! This f***in rocks!”

The during is pretty standard. I assume we all just start muttering and mumbling profanity as we get closer to our machines in anticipation of needing it. Gotta get limber to really curse well. Going in cold leads to really weak “expletives” that will get you serious side-eye from the neighbors, and pity from the dog. And the truce you finally, grudgingly, forged with the cat? Gone; it knows you’re a push-over, and you’re dead the next time you fall asleep on the couch…

I lived in Korea for a bit and was completely broke - I ended up renting a shared workspace and made a vox phantom clone from bits of scrap plywood I found around the place and a jigsaw - pickups were 3d printed (first time I’d seen a 3d printer in action!) and wound on a drill, it’s still one of my favorite guitars I’ve owned - The finish was charred plywood sealed with a can of polyurethane I found.

Pickups wound to 4kOhm while tensioning the wire with cotton work gloves, dipped in the same polyurethane used to finish the guitar, it screamed if the volume got too loud, but it sure was cool sounding!

Sadly, I lent it to a friend who ended up chucking it out.

I will see if I an find the old pictures of how i did the neck and post them here. The Neck files that I used had the basic radius in the CNC files and I finished the final radius using a radius block, which I also made on my old homebuilt CNC router. Let me find those pictures and post them it will probably help make sense of how it was done.

I just about have my LR3 completed and I will probably do a body neck (Telecaster) once it’s complete and document the process with pictures and post it here in the near future.